Industrial Fasteners Manufacturer

Rax Industry industrial fasteners are also called hardware fasteners and electrical fasteners. These fasteners are just one small part of the steel fasteners. Rax Industry only pays attention to the industrial fastener used on overhead line construction.

Rax Industry industrial fastener includes double arming bolt, eye nut, forged eye bolts, hex bolt and nut, pigtail bolt, square head machine bolt, thimble eye bolt, u bolt, upset bolt, washers, etc.

Rax Industry Industrial fasteners are mainly used on pole lines, power transmission lines, and overhead power lines. They are ideal to connect the pole line hardware or ADSS/OPGW accessories.

Industrial fasteners are made of carbon steel. The finish is hot-dip galvanized.

As a professional industrial fastener manufacturer, Rax Industry has successfully developed many kinds of eye bolts and eye nuts, including square washers.

Rax Industry is a leading industrial fastener manufacturer, based on longtime experiences working with different market customers. Our industrial fasteners have different standards. We have made the ANSI, BS, and GB standards according to different customer requirements. Rax Industry knows the standard, knows the technology, and knows your needs.

All the Rax Industry industrial fasteners are hot-dip galvanized according to ISO 1461 or ASTM 153. The main process in making the industrial fasteners are hot forged, in this way, these fasteners are working well on the overhead line. Rax Industry is a faith industrial fastener manufacturer, unlike some suppliers to do cold-forged industrial fasteners to lower the quality. And Rax Industry has its own secret to making the thread smooth after it hot-dip galvanized. Rax Industry pays attention to every detail and every step.

Industrial Fastener: The Definitive Guide

- Chapter 1: What is Industrial Fastener?

- Chapter 2: Types of Industrial Fasteners for Tower & Pole Lines

- Chapter 3: Industrial Fastener Material

- Chapter 4: Industrial Fastener Standards

- Chapter 5: Industrial Fasteners Terminologies

- Chapter 6: How to Install Industrial Fasteners in Pole Line

- Chapter 7: Conclusion

- Chapter 8: FAQ

Whether you are working on transmission or distribution pole lines, you’ll obviously secure other hardware.

That’s why you need high quality and reliable industrial fasteners.

They come in different shapes and sizes, made from different materials.

Today, I want to walk you through everything you need to know about industrial fasteners.

From terminologies, material, dimensions, quality standards to types of industrial fasteners.

Keep reading to learn more.

What is Industrial Fastener?

An industrial fastener is a device that affixes, attaches, or joins other pole line hardware on the transmission line.

In most cases, they form a non-permanent joint.

Industrial fastener is known as hardware and electrical fasteners.

Fasteners in a transmission line

Generally, industrial fasteners include oval eye bolts, double arming bolts, square head bolts, U bolt, square washers, thimble eye bolts, hex bolts and nuts, pigtail eye bolts, and others.

These fasteners are used mainly on power transmission lines, pole lines, and overhead power lines.

You can use them to attach pole line hardware or OPGW or ADSS accessories.

Types of Industrial Fasteners for Tower & Pole Lines

As I mentioned earlier, there are many types of industrial fasteners for tower and pole lines.

They include the following:

· Eye Nut

Below is what we refer to as an eye nut:

Eye Nut

Eye Nut

Eye nuts are pole line accessories that are used for back-guying, dead-guying, and connecting pole head guys on threaded ends of cross arm bolts.

They do not offer many benefits when you use them on overhead power lines and pole line construction.

Eye nuts mostly include:

- Eye nuts

- Angle thimble eyelets

- Oval eye nuts.

The thimble eye nut mostly includes:

- Thimble eye

- Twin-eye

An oval eye nut is designed for ½ or 5/8 inch threaded end machine bolts, vertically passing via cross arms to connect dead-end clamps.

The design of eye nuts makes installation easy and simple.

Eye Nut

Eye Nut

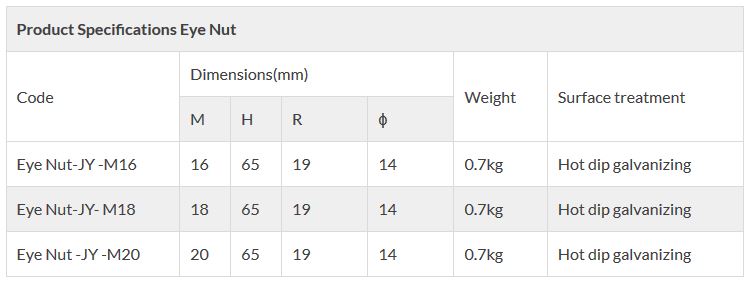

Eye Nut Technical Specification

Thimble eye nut is brought together with thread end of ½ or 5/8 inch eye bolts.

These go across wooden poles to aid strain insulators to dead-end clamps.

In most cases, we use drop forging to make eye nuts and they are made from steel rod.

Eye nut technical data

· Double Arming Bolt

Well, below is a picture of this hardware accessory

Double arming bolt

Double arming bolt

Double arming bolts also are known as double threaded bolts or double ended bolts.

They are used mainly for pole line and overhead line construction purposes.

This is why you see them more on such construction sites.

Double arming bolts are used mainly on cross arm and pole line constructions.

Normally, the threads go through the pole, while the two ends are locked or secured with washers and bolts.

The design of the double arming bolt is mostly in a straight form.

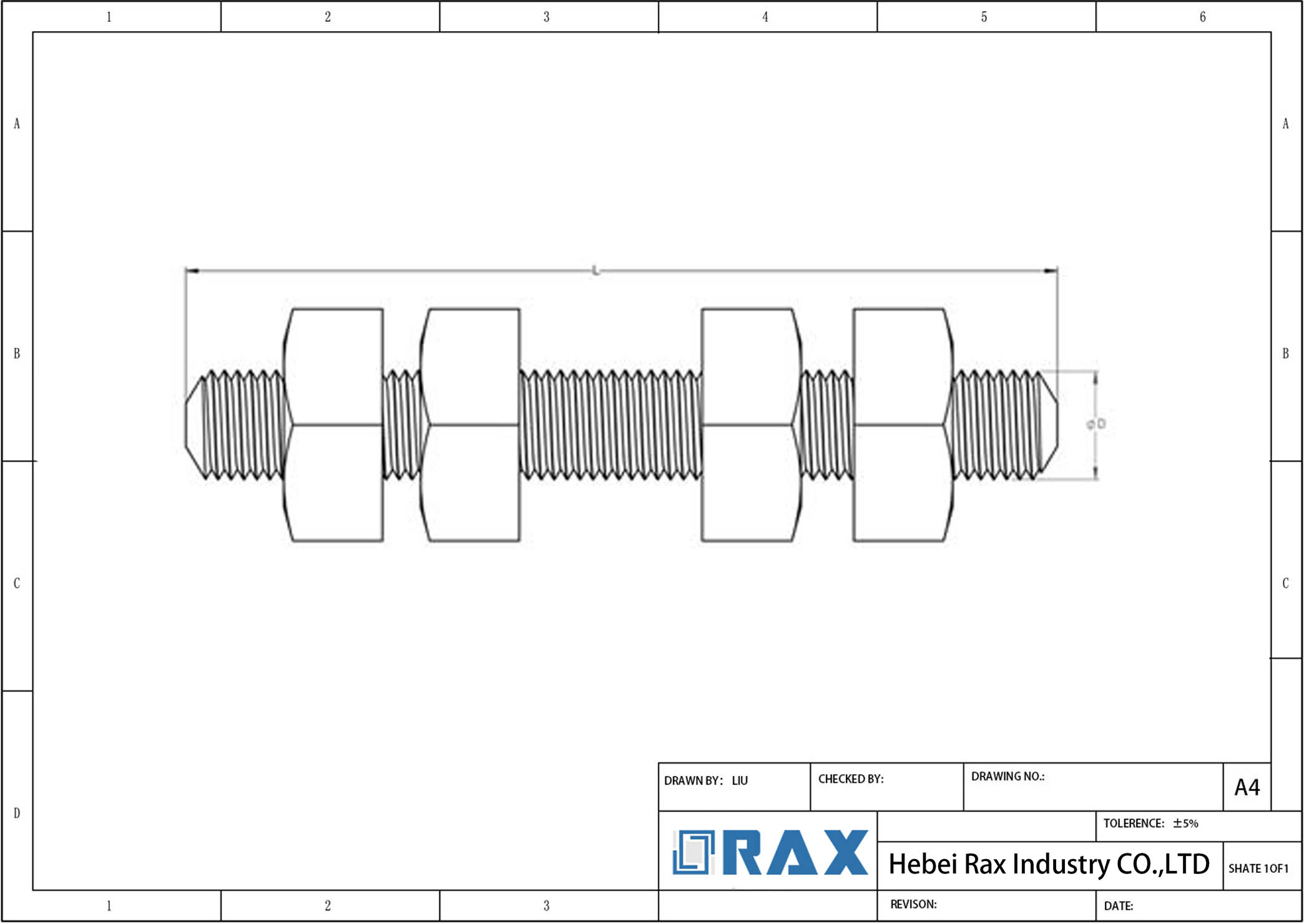

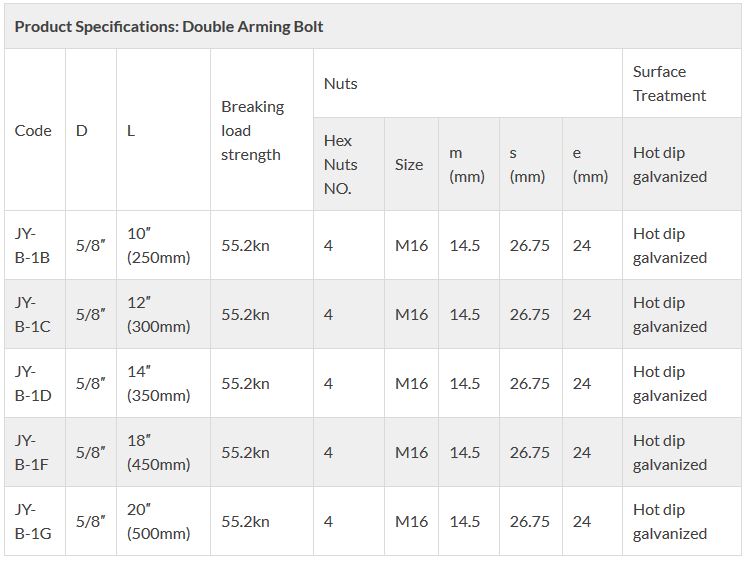

Technical specification of double arming bolt

Technical specification of double arming bolt

Double arming bolt technical specifications

Some of the main specifications you need to consider include:

a) Length

The length of double arming bolts is measured from its last thread, end to end devoid of cone length.

Based on the length of threads, double arming bolts will include double threaded bolts and all thread bolts.

The length of these hardware accessories will always differ from one user to the other.

Just make sure you choose right.

b) Strength

You must know that its strength levels also differ.

Double arming bolt weight is rated 12400 pounds of tensile strength.

Knowing this will help you to benefit in many ways especially when you decide to make choices.

c) Sizes

They come in different sizes.

You can find full thread double arming bolts and two end thread double arming bolts.

Their sizes are mostly ¾ inch and 5/8 inch.

d) Assembling

Each double arming bolt comes with hex nuts or four square nuts.

e) Design

All double ended bolts are designed to come with chamfered round ends or semi-cone ends.

These cones point at all ends of the bolt.

It helps you drive and remove it from poles with ease with no damage to the thread.

f) Diameter

It comes in different diameters.

However, the most used diameters are 5/8, 1/2, and 3/4 inches with diverse lengths.

Most double arming bolts are made from hot-dip galvanized stainless steel.

Technical specification of double arming bolt

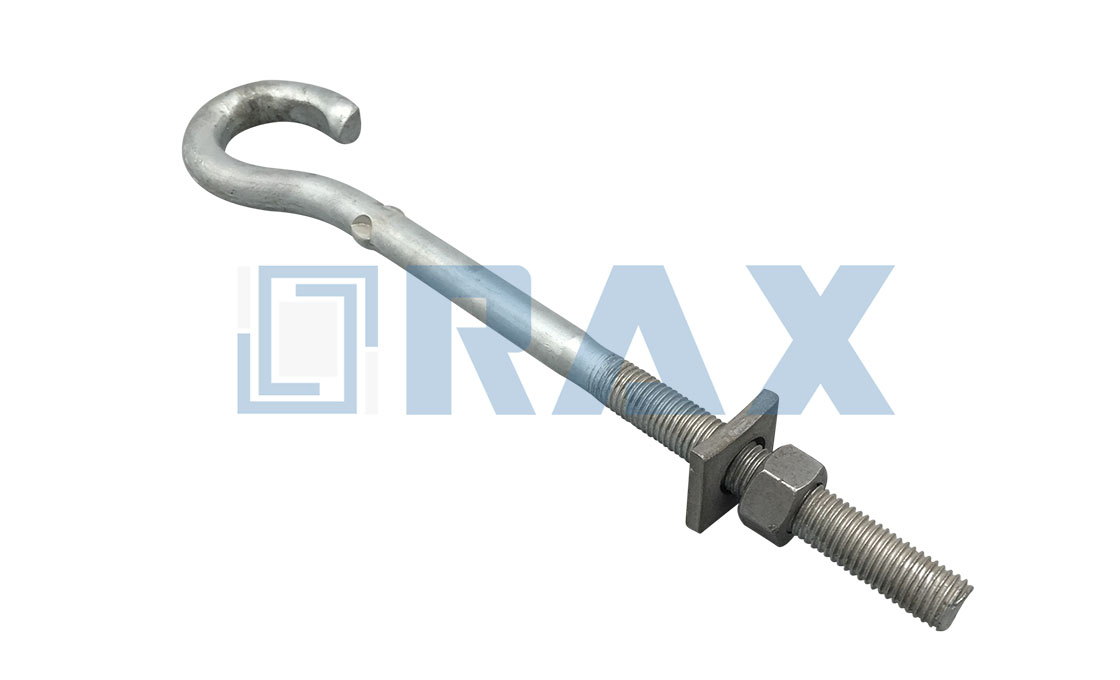

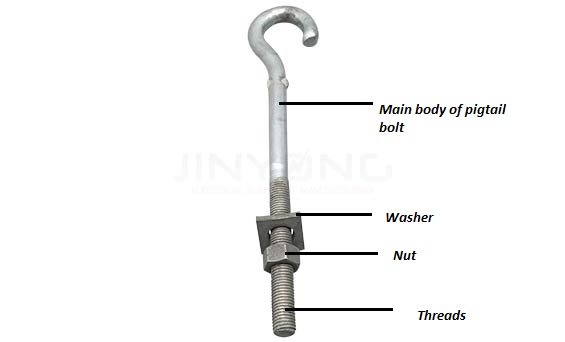

· Pigtail Bolt

Pigtail bolts also are known as pigtail eye bolts, pigtail screws, pigtail hooks, pigtail fasteners; is unique pigtail hardware.

Pigtail bolt

Pigtail bolt

Pigtail bolts are also unique industrial fasteners that are designed for use on concrete, power line, or wooden poles.

They are used on these to hang dead-end clamps or suspension clamps.

The applications of pigtail bolts are mostly on wooden poles, concrete poles, and other power lines.

This is to ensure suspension and dead-end clamps are hanging right.

This is because the helical ends of these bolts are just like pigtails.

This is why it is called a pigtail bolt or a pigtail hook.

Look at this:

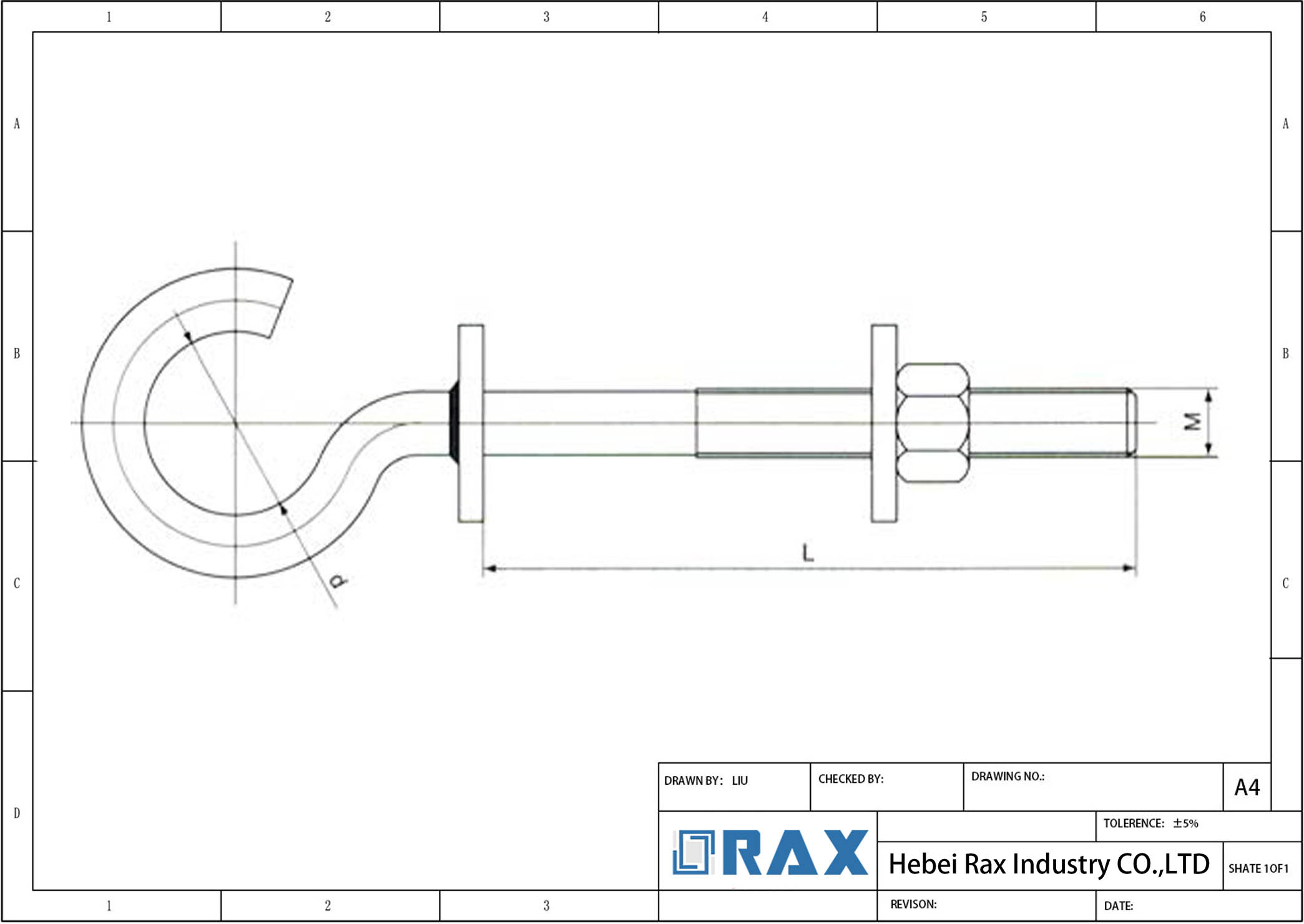

Technical drawing of pigtail bolt

Technical drawing of pigtail bolt

Pigtail bolts that are used in Kenya and Zambia are made with a square or round washer on the pigtail hooks neck.

Below is one different look at the pigtail hook:

Pigtail bolt design

Pigtail bolt design

Pigtail bolts that are used in Malaysia come with additional two forged points.

This is mostly on their left and rides neck sides close to the hook.

The unique design helps to prevent it from falling off or dropping off.

· Pigtail bolt technical specifications

When you purchase pigtail bolts, it comes with:

- One piece of pigtail hook main body

- Two hex nuts

- Two washers

Also, when pigtail screws are installed on wooden or concrete poles, hex nuts and washers are used to fasten the end on pole sides.

Other pigtail ends are used in linking suspension clamps.

There are also pigtail bolts that have no screws.

It is only with round ends.

There is no major difference between pigtail bolts and pigtail screw hooks.

The difference is just with the shape of the end.

Pigtail screws have sharp ends.

Pigtail bolt specification

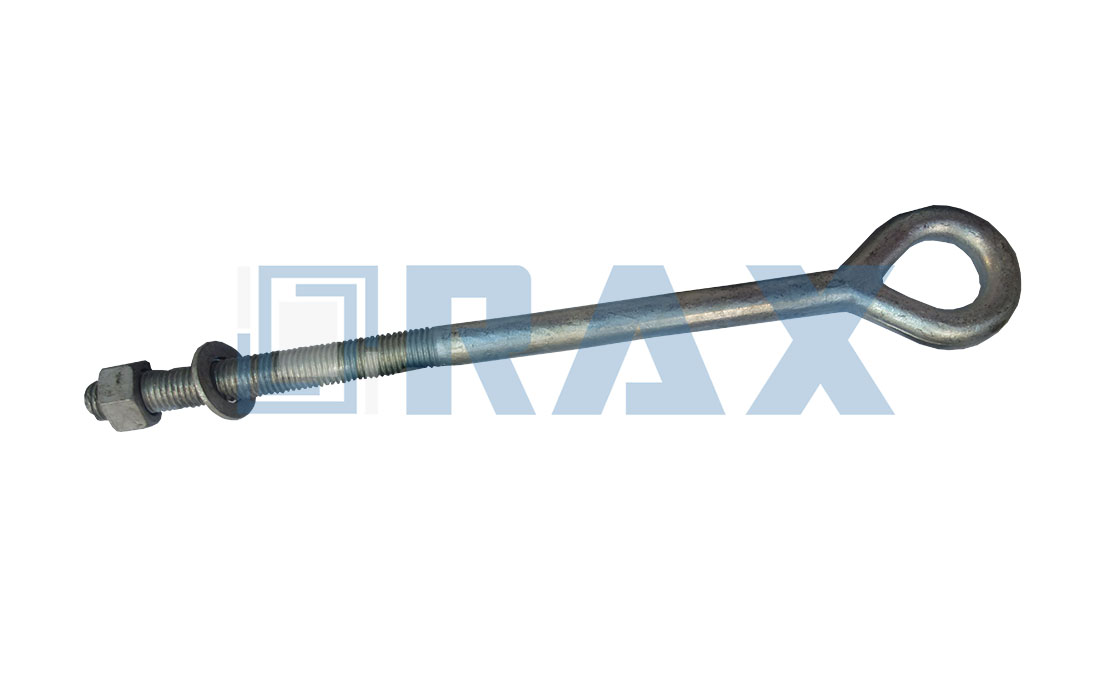

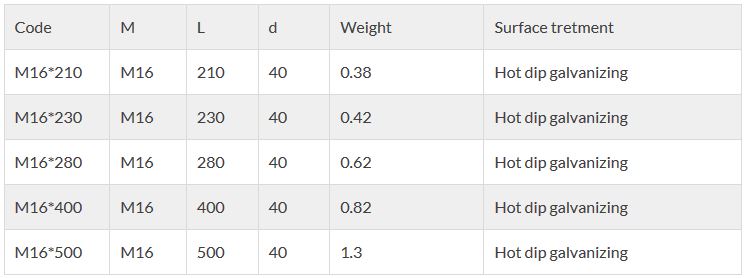

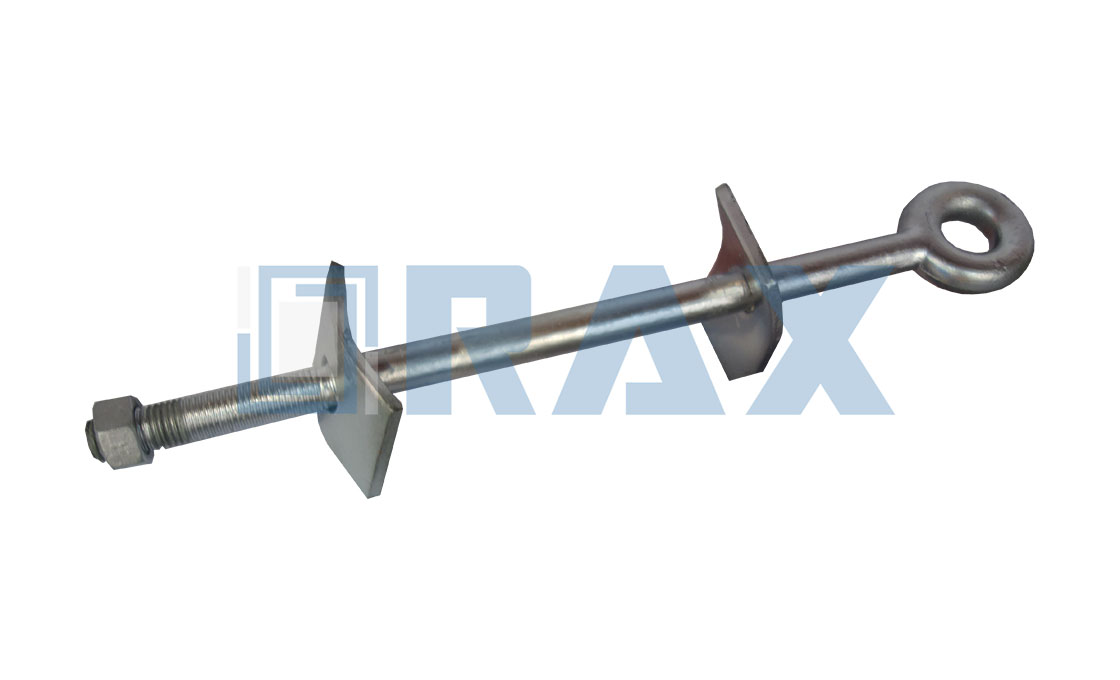

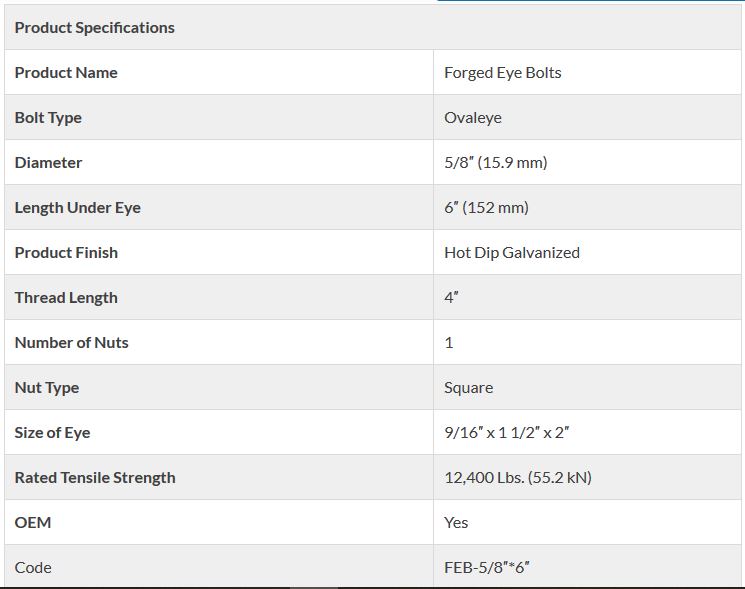

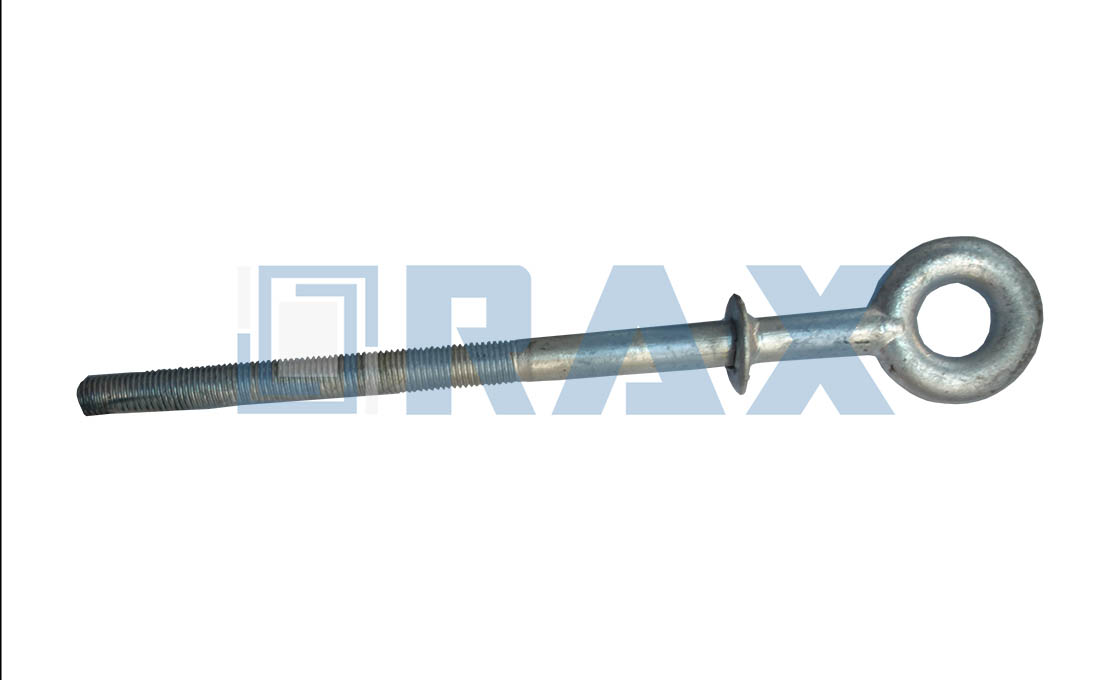

· Forged Eye Bolts

Have you ever seen this before?

Look at this:

Forged eye bolts

Forged eye bolts

Forged eye bolts are also known as forged eye-bolt or drop forged eye bolts.

They include oval eye bolts and round eye bolts.

Forged eye bolts are used in electrical and overhead line dead-end insulator connections.

Forged eye bolts come in oval and round eye bolts.

Oval eye bolts are used mainly on wooden poles to connect dead-end insulators in electric power or overhead lines.

Oval eye bolts are mainly designed with over thimble heads known as locked circles when they are linked with dead-end insulators or clevis.

It doesn’t easily drop.

Technical drawing of Forged eye bolts

Forged eye bolts are assembled with square or hex nuts.

This fastens over eye bolts when going across wooden poles.

· Forged eye bolts technical specifications

Forged eye bolts are mainly hot drop forged.

Dropped forged eye bolts do not have welded points.

Load breaking; forged eye bolts are highly resistant to load breaking than welded eye bolts are.

Forged steel eye bolts always have a breaking load of 50kn for 5/8” and 55kn for 3/4″.

Diameter; this diameter mostly includes 3/4″ and 5/8”.

Thread length; the thread lengths under eye are 6”.

What is the surface treatment for forged eye bolts; the surface treatment for forged eye bolts is the hot-dip galvanized method.

This treatment method has no zinc blocks on screws.

At times, manufacturers may sprinkle oil on threads for a smooth installation.

Forged Eye Bolts

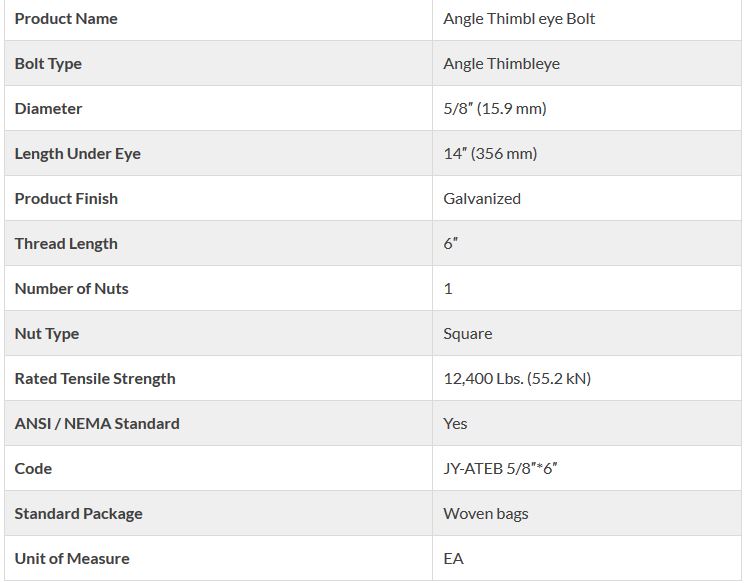

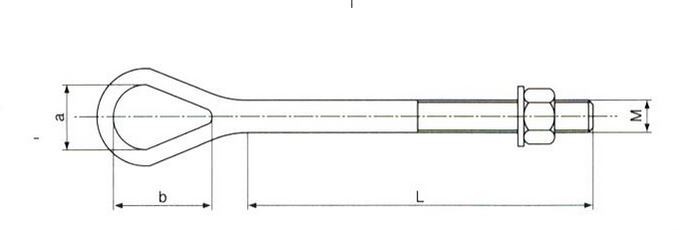

· Thimble Eye Bolts

Have you seen it before?

This is how thimble eye bolt:

Thimble eye bolt

Thimble eye bolt

Thimble eye bolt is a unique eye bolt type that is used mainly on pole lines or overhead line constructions.

Thimble eye bolts are used together with thimble eye nuts for all projects.

They are suitable for overhead lines, communication lines, and electric lines.

Thimble eye bolt mostly includes straight thimble eye bolts.

The angle thimble eye bolts are a bit curved.

The smooth curve within the middle of thimble eye bolts is a perfect design to have the link of guy grip loops achieved.

Thimble eye bolt

Thimble eye bolt technical specification

The process involves hot forging metal.

Then, you can go ahead to hot dip galvanize the final product.

When steel rods are heated by electric furnaces, red rods are taken to friction punch machines.

These machines press them to have the thimble eye shape you see.

Some of the main parts of thimble eye bolt include:

Thimble eye bolts do not come with welded parts.

Strength; the tensile strength level of 13550 pounds for a 5/8” diameter bolt and 20050 pounds for a 3/4″ diameter bolt.

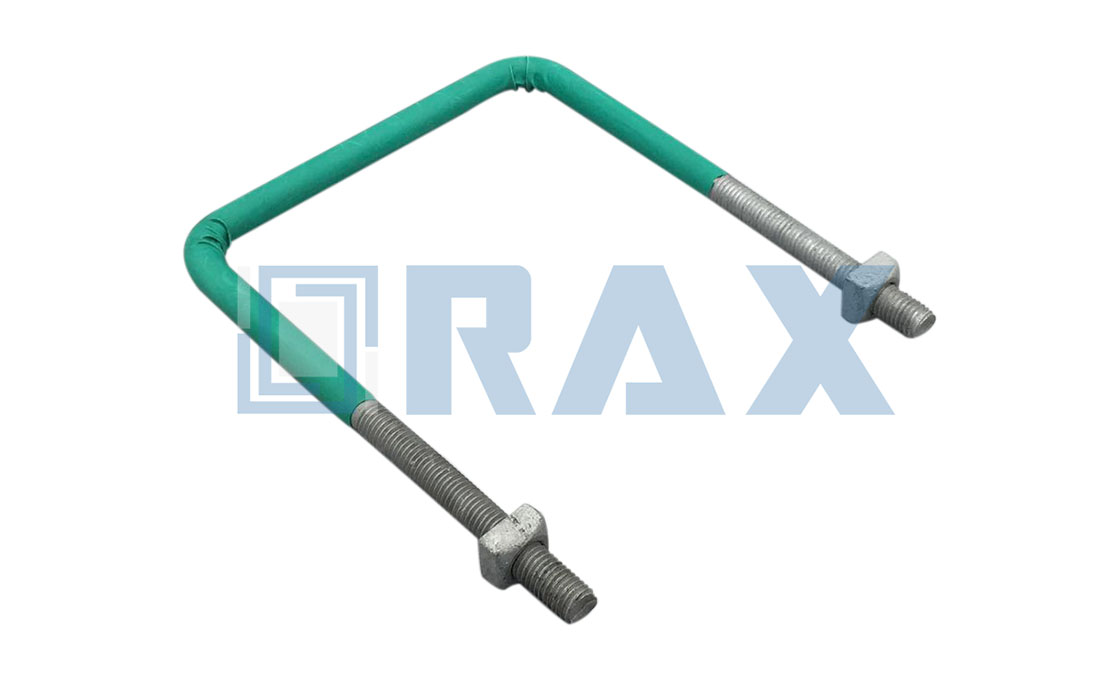

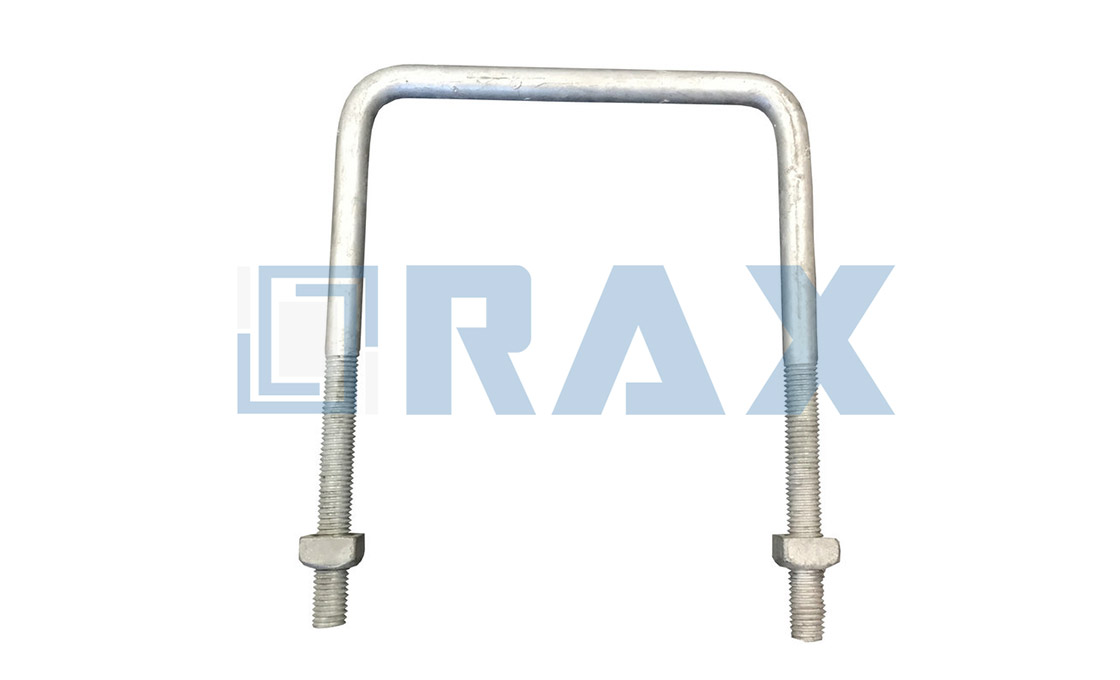

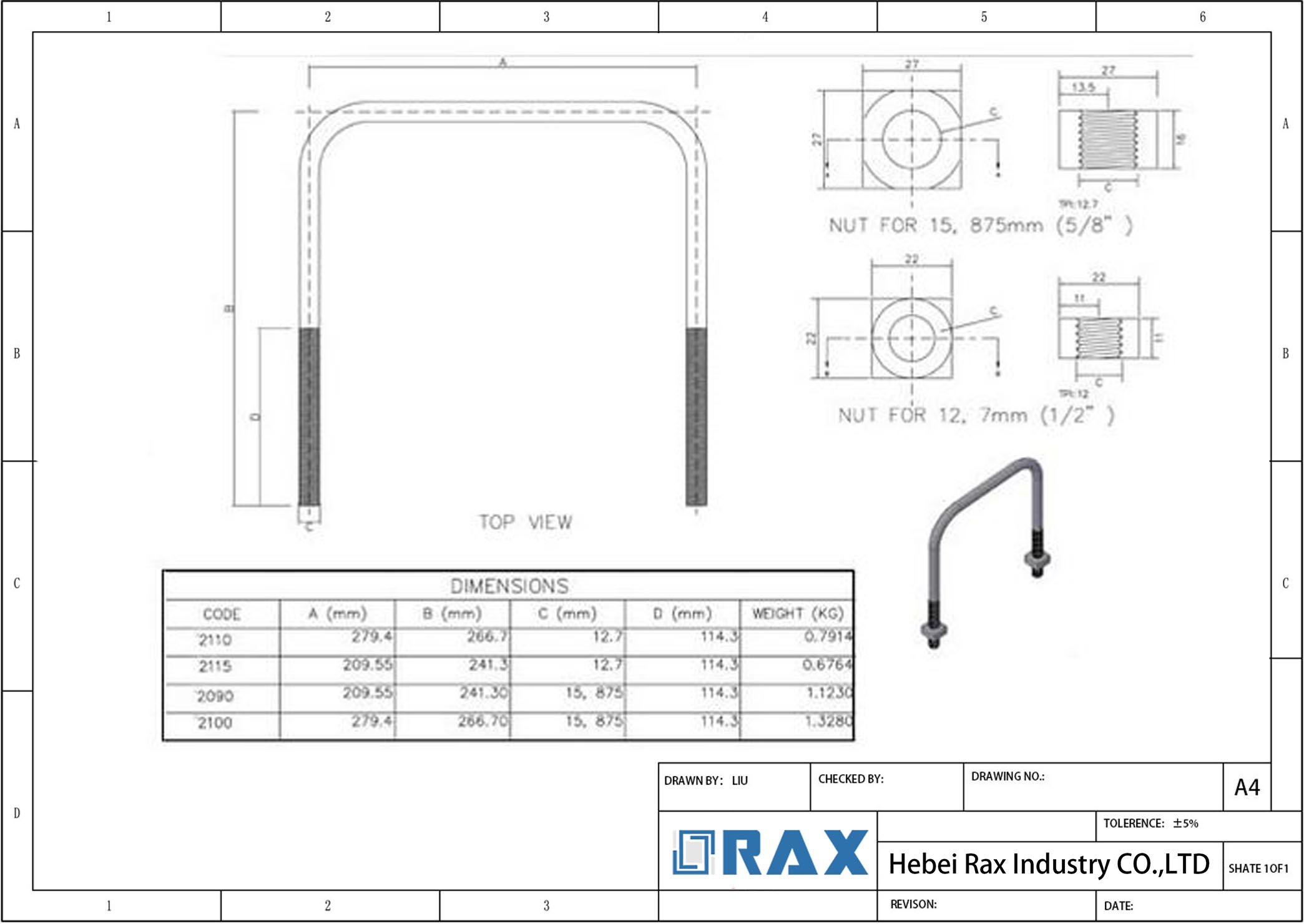

· U Bolt

Here is an example of a U bolt.

U bolt

U bolt

U bolt is mostly used on electric power lines, concrete lines, and pole lines.

Technical drawing of U bolt

U bolt comes designed in both big and small types.

The small type is used in linking ball sockets and tension clamps on transmission lines.

There are quite a number of designs of U bolt.

This is because different countries tend to use different designs of U bolts for projects.

You will find square U bolts and middle bandage U bolts.

They are both installed on concrete poles to have cross arms fastened.

A small U bolt is however used in linking a tension clamp and ball socket on a transmission line.

U bolt technical specification

U bolt treatment; U bolt surface treatment is hot-dip galvanization.

The thickness of zinc protects the surface from rust. T

Thread; U bolt thread is made by rolling machines.

These threads come in 1/2″, 3/4″, and 5/8” diameter screws.

Strength; High-quality U bolt is hot forged and not cold bent.

Hot forged types guarantee the highest loading strength when used for overhead lines.

Oil is sprinkled on high-quality U bolt to ensure a smooth installation process.

· Hex Bolt and Nut

You might be wondering or asking yourself what hex bolts and nuts are and what they look like.

Well, below is a picture to settle this confusion you have in your mind.

Hex bolt and nut

Hex bolt and nut

So, now that you know what this hardware accessory is, what is it used for?

A hex bolt and nut is also known as hot-dip galvanized bolt and nut or galvanized bolts and nuts.

They are used mostly on overhead power lines and power transmission lines.

Additionally, hex bolts and nuts are used to fasten pole line hardware or power line accessories.

Hex bolts and nuts are hot forged.

Steel rods are heated to become red-hot with an electric stove.

After that, red rods are punched to become the hexagon head design that they come in.

Its screws are made from rolling machines.

· Hex bolt and nut technical specifications

Material; hex bolts and nuts are made from steel rod.

Diameter; The most common hex bolts and nuts diameter include 1/2″, 3/4″, and 5/8”.

Thread; Hex bolt and nut thread run from a 100m – 400mm range.

Hex bolt and nut surface treatment are hot dip galvanized.

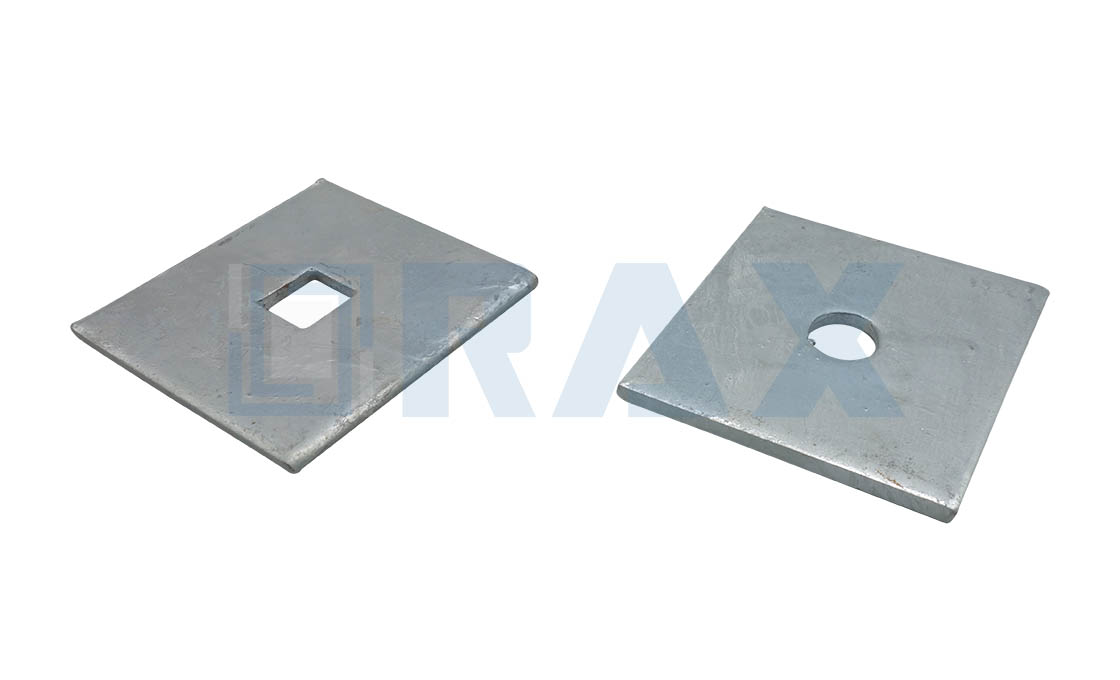

· Square Washers

Below is an example of square washers:

Square washers

Square washers

Mostly, when you purchase square washers they come with curved washers, spring washers, and square washers.

You can use these washers with pigtail bolts, square bolts and nuts, oval eye bolts, hex bolts and nuts, and thimble eye bolts.

Flat square washers are used more on concrete pole lines.

They are used to stop eye bolts from dropping off.

Curved washers are used more on wooden poles.

Curved structures are ideal for raised surfaces of wooden poles.

Square washers come in different designs for a range of applications.

As you have seen from the above designs, square washers have holes in the middle.

The diameter of that hole mostly depends on the eye bolt diameter.

Square washers’ technical specifications

Sizes; flat square washers come in different sizes for different uses like 50*50*3mm, 75*75*6.35mm, 60*60*4.75mm.

Raw material; the raw material for making a square and curved washer is flat steel, flat steel that is cut into its ideal sizes.

Assembling; spring washers are mostly assembled with bolts and nuts.

Spring washers make fastening extra tight to keep work intact.

Galvanizing method; square, spring, and curved washers are hot dip galvanized.

Galvanizing is done to protect them from rust.

Industrial Fastener Material

You must consider the types of material when choosing an industrial fastener.

It should be a material that will withstand the loading capacity.

Fasteners are made from different materials such as steel, aluminum, bronze, stainless steel, copper, brass, nickel, titanium, and some other non-ferrous metals.

Also, they can be made from plastic and other exotic materials.

With this in mind, there is more you should know.

Hot dip galvanized industry fastener

The selection of materials depends on:

- Strength needed

- Weight

- Stresses

- Corrosive environment

- Electrical conductivity

- Magnetic properties

- Reusability

- Coatings / platings needed

- Expected or anticipated life

Moving on, you must know that more than 90% of industrial fasteners are made from steel.

This is due to the inherent strength properties of steel, its absolute cheapness, and ideal workability as compared to all other materials.

There are mainly 3 types of steel used in manufacturing industrial fasteners.

They are:

- Low carbon steel

- Medium carbon steel

- Alloy carbon steel

Below are some more details on these unique steel materials.

· Carbon steel industrial fasteners

Carbon steel mostly contains lesser than 0.25% carbon.

It comes with its unique ductility and strength.

It is machined and welded with ease and is moderately reasonable in price to manufacture.

It has tensile potency of between 60,000 psi to 80,000 psi.

· Stainless steel industrial fasteners

Stainless steel industrial fasteners are alloy steels that come with less than 0.5% chromium content.

Chromium presence is what creates chromium oxide which is an invisible surface film.

This film is what resists oxidation and ensures metal is resistant to corrosion or passive.

· Aluminum industrial fasteners

Aluminum is a metal that is light in weight.

It, however, has a high level of strength to weight ratio.

Aluminum has the best corrosion resistance in many environments, and ideal electrical and thermal conductivity.

Generally, aluminum is very popular in the world of industrial fastener materials.

· Bronze industrial fasteners

Often known as silicon bronze, it is an alloy that is made more of copper and tin with fewer silicon amounts.

Most times, aluminum or manganese are included for strength.

Lead is included to make it easy to machine.

Based on its make, silicon or bronze has a high level of tensile strength.

It is mainly used for marine purposes due to its high corrosion properties, non-magnetic features, and its ability to resist saltwater corrosive action.

· Brass industrial fasteners

Brass industrial fasteners are compositions of copper and zinc.

They are the most common copper based alloys.

Brass industrial fasteners resist corrosion and are highly conductive (conduct electricity).

However, its use as an industrial fastener is limited due to its unique softness.

Also, it is popular due to its unique and elegant look.

· Non-metallic industrial fasteners

Non-metallic industrial fasteners are mostly used for their appearance and non-corrosive properties.

They are, however, used for specific purposes only.

And by the way, even as you shop for a suitable industry fastener, you need to control all the dimensions.

Industrial fastener dimensions

Some of the main dimensions you should consider include:

- Nominal size

- Body diameter

- Head thickness

Of course, the dimension will depend on the type of industrial fastener in question.

I hope you can remember what I discussed earlier.

Industrial Fastener Standards

A high-quality industry fastener must meet certain quality standards.

These may include:

· American National Standards Institute (ANSI)

The American National Standards Institute is always responsible for endorsing industrial accessories that are of the right quality.

This is why you will find many brands interested in obtaining their endorsement.

· International Organization for Standardization (ISO)

Most online manufacturers of various electrical products and accessories require ISO or International Organization Standardisation to produce and sell.

This should tell you how important their standards are.

· DeutschesInstitutfürNormung (DIN)

When a manufacturer has the DIN endorsement, it means they mean business.

This is why you will find many brands interested in obtaining their endorsement.

· Japanese Industrial Standard (JIS)

Like other quality standards, a good industrial fastener must conform to the JIS.

It is only through this that you can trust it for any industrial application.

Industrial Fasteners Terminologies

These terms are mostly heard a lot when industrial fasteners are been used.

Industry fastener

Check them out so that you aren’t surprised at all when you hear any of them.

· Bolt length

This is mostly the length of bolts used in the installation.

These lengths always vary depending on the fastener being used and the sizes involved here.

· Thread length

Threads are used more in ensuring assembling and fastening are done right.

Their length is also something that always comes up as a very important part of industrial fasteners and their use.

· Head

Head is where force is exerted for installations.

For instance, bolts have a head that is hit to enter into holes or points.

· Thread

It is these threads that allow you to assemble and tighten industrial fasteners.

· Nut

Nuts are used to hold and keep bolts fastened.

Also, nuts help in keeping the entire installation process intact.

· Point

This is used mostly where the bolts are installed to fasten wires and other cables.

How to Install Industrial Fasteners in Pole Line

There is always a lot of confusion when the issue of installing industrial fasteners in pole lines is talked about.

Well, this guide is here to help.

Installing industrial fasteners in pole lines always differs from one person to the other.

Below are some important specifications to know when installing industrial fasteners in pole lines.

Step 1: Choose the right industrial fasteners. Therefore, you should consider appropriate dimensions, quality standards, and type of material.

Step 2: Have all the necessary safety gear in place. These may include helmets, industrial boots, gloves, etc.

Step 3: Pick appropriate tools for the task. You may need holding and fastening tools or accessories.

These may include pliers, screw drivers, drilling machines, holding equipment, etc.

Step 4: Now assemble the equipment you want to assemble. Put them together, insert faster and tighten.

NOTE: The installation process will depend on the type of industrial fastener you’re using.

For example, the process of installing eye nut or U bolt may vary slightly.

Always check the technical information an industrial fastener comes with.

Conclusion

So, you now understand the uniqueness of industrial fasteners.

All industrial fasteners come with unique features and specifications.

This makes them very important and needed in various pole lines, electrical, and communication projects worldwide.

Due to this, I believe you will want to make high quality and yet affordable purchases always.

That is where Rax Industry comes in.

Compared to the other manufacturers on the market, we at Rax Industry stand out to deliver and provide high-quality industrial fasteners at the best prices.

Rax Industry delivers different types of these accessories with regards to size, design, colors, etc. worldwide.

Talk to us today – we will help you choose a suitable industrial fastener.

FAQ

What are industrial fasteners?

Industrial fasteners are a series of fasteners which used to fasten and connect the pole line hardware and power line fitting.

What are the production standards of industrial fasteners?

Production standards of industrial fasteners are different in different markets, such as ANSI, BS, DIN, UNI, and GB. We only manufacture industrial fasteners based on the standards ANSI, BS, and GB.

What industrial fastener dimensions can you supply?

The widely used Industrial fastener is 3/8, 5/8 and 3/4. We can also manufacture other sizes according to your required details.

Are you a manufacturer or a trading company?

We are an industrial fastener manufacturer located in Hebei China.