Pole Line Hardware

Pole line hardware is also named pole line accessories or pole hardware fitting, it is an important component of pole line construction. According to the application, it can be divided into telephone pole hardware, utility pole mounting hardware, or utility pole line hardware.

The pole line hardware is joined together to make the installation come true, it is not only supporting the power line but also protects the power line from flowing. The full line of the hardware needed for power utility applications includes anchor rod, guy clamp, pole band, secondary clevis, secondary rack, stay rod, street light arm, yoke plate, etc.

Utility pole mounting hardware is a quality utility power line part and accessory for the electrical market all over the world.

For different raw materials, there are different processes. For the angle steel, the process involves cutting, punching, welding, and bending. For the steel rod, the process is hot forged.

Pole Line Hardware: Strength, Durability, and Safety Guaranteed

Be in any major city in the world, or any place that has modern amenities like electricity and communications, utility pole hardware is necessary, which ensures the smooth functioning of these facilities for the modern man.

Rax Industry utility pole hardware has the features as below :

1)Hot-dip galvanizing according to ISO 1461 with no ribs, no lumps, and no omissions.

2) Raw material carbon steel which is new and no recycles.

3) Uniform on the size and high breaking load to guarantee the stable. When you work with Rax Industry, the specialty and service will impress you so much.

Rax Industry doesn’t only sell pole line hardware to you but also supplies you with the best solution to make your business take off.

Pole Line Hardware: The Complete Guide

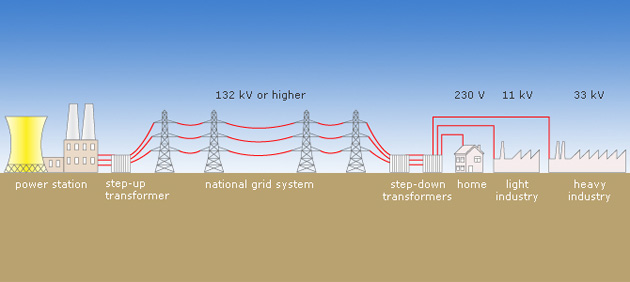

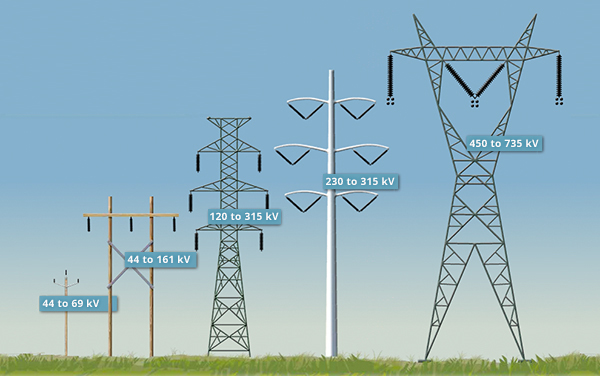

High voltage power transmission

Are you looking for suitable hardware needed for power utility applications on high-voltage or low-voltage power transmission? If yes, then this is a must-read guide for you. Because I am going to take you through every aspect of the utility pole hardware. From basic definitions, classifications, consideration, materials, installation to applications of pole line hardware – you will learn everything you need to know here. Just keep reading to be an expert in pole line hardware.

- Chapter 1: What is Pole Line Hardware?

- Chapter 2: Why You Need Pole Line Hardware?

- Chapter 3: Classification of Pole Line Hardware

- Chapter 4: Key Consideration when Buying Suitable Pole Line Hardware

- Chapter 5: Pole Line Hardware Materials

- Chapter 6: Types of Pole Line Hardware

- Chapter 7: Installing a Pole Line Hardware

- Chapter 8: Your Premier Manufacturer in China

- Chapter 9: Conclusion

What is Pole Line Hardware?

If it’s your first time buying or import pole line hardware, then possibly you wouldn’t don’t know sufficient information about the same. And this is probably one of the daunting questions that could be running in your mind as you read this guide. Essentially, pole line hardware refers to the different types of parts and components used commonly in the aerial construction of overhead lines.

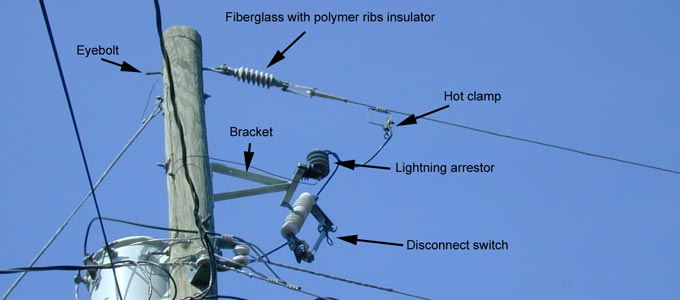

Example of pole line hardware – Photo courtesy: Power Line Hardware

Power pole hardware is widely used in connecting, handling and holding various overhead line systems, insulators, wires, and other untilites. They come in different types, sizes, and designs. Of course, this uniqueness is a result of the fact that their purpose is also different.

Nonetheless, it is the particular application that determines the type of utility pole hardware you’ll require for your needs. These pole line accessories are vital in various aspects of overhead line construction since they ensure efficiency, safety, and convenience.

As you’ll come to realize later in this guide, several types of pole line hardware play a distinct role in their specific applications.

For now, though, let’s shift focus and look at some of the reasons that would possibly acquire pole line accessories worthwhile.

Why You Need Pole Line Hardware?

Quite evidently, the use of pole cable accessories is widespread. It is a clear indication that people need it for different reasons. So let me describe to you a few beneficial reasons why you would necessarily require accessories for pole cables;

a) Safety

You see, the power lines are ordinarily hazardous. These are not the usual things you would wish to gamble with at any cost. So necessarily, most of the pole line hardware is needful as a way of enhancing the safety of the power materials.

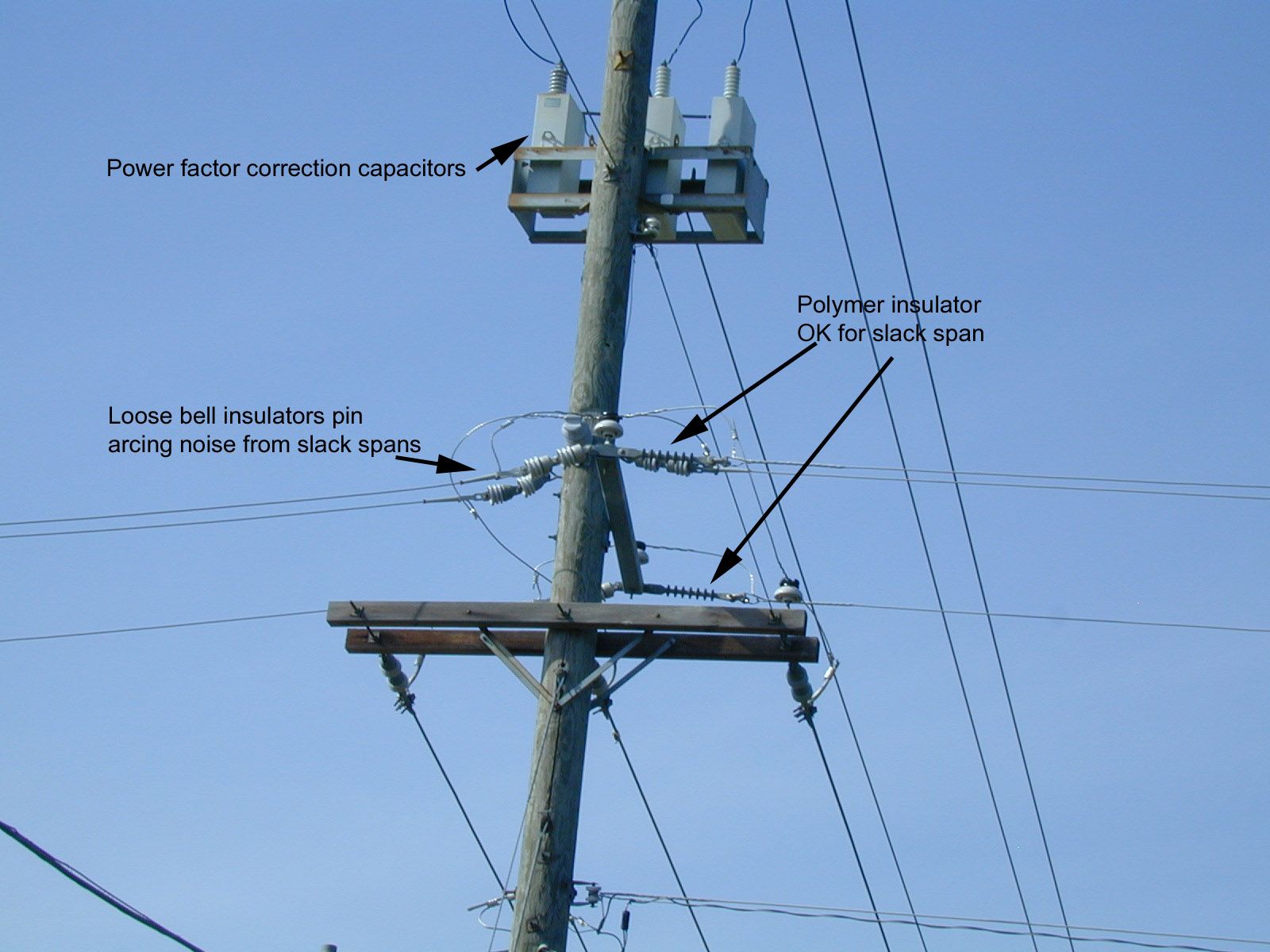

Power line safety

In most instance, such hardware help to hold the various cables, insulators, transformers or many other elements in position. They also assist in safeguarding many critical components from falling or causing a threat to the user in one way or the other. A bigger picture in this case, therefore, is that you require these accessories as a way of safeguarding the lives and properties of people.

b) Compliance

Ordinarily, pole cable hardware is extremely under strict regulations posing to the nature of the role they play in the respective application. What I mean here is that it’s entirely impractical to merely use any type of this accessory that doesn’t meet the standards of the industry.

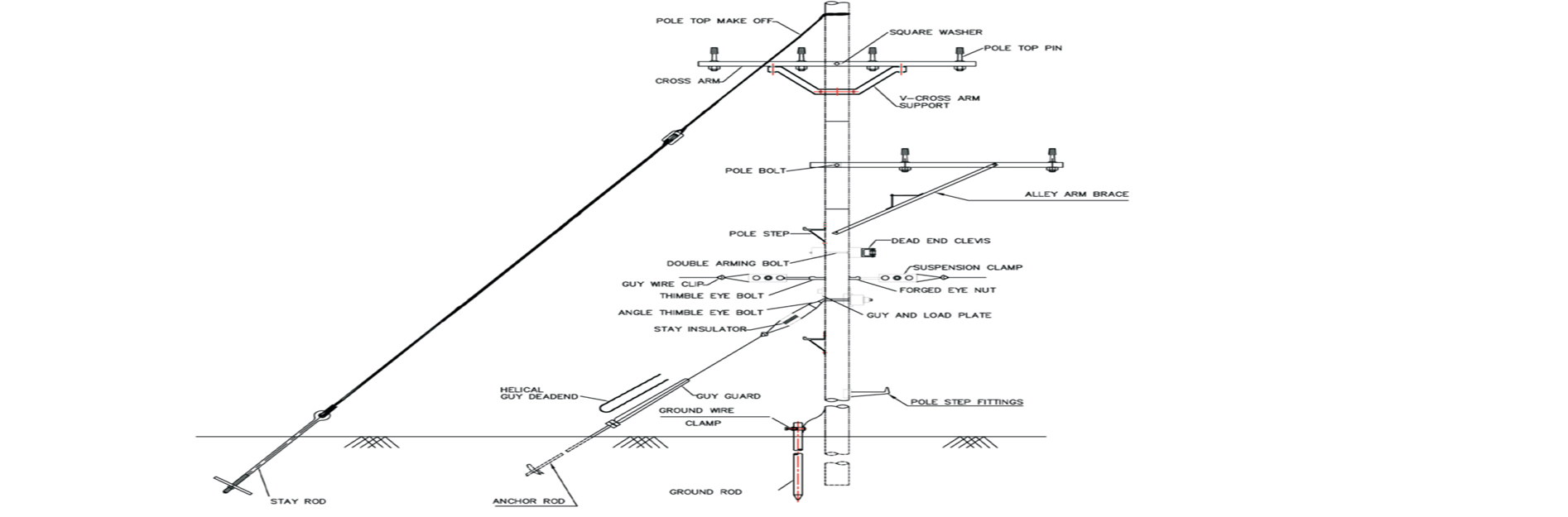

Installing power line hardware

So you’d seemingly require these components as a way of complying with the standards that the regulators have put in place. Indeed, there are various instances where you cannot install a specific type of overhead line without using particular pole line hardware. And for that reason, it becomes vital to comply with the industrial standards possibly as a way of enhancing safety too.

c) Easy Maintenance

There is something vital that you ought to know regarding these items and so let me explain briefly; It is relatively easy to maintain an overhead line as opposed to an underground line. You see, what you got to in most cases is merely to climb the poles and make the necessary adjustments and repairs.

So you need these types of hardware because they make your work easy, faster and convenient. It is also easy to monitor the status of pole line hardware from time to time and determine the specific ones which require repair or replacement. And for that reason, you’ll attain the necessary efficiency in whatever application you’re handling.

d) Convenience

Like I have mentioned in the earlier point, pole line hardware offers the suitability of the highest level. This is obvious in the aspect of installation, maintenance, replacement, and repairs.

Different types of pole line hardware

What happens in most cases is that you’ll spend the relatively short time to do all the things on overhead lines. All you got to do is making sure that you have the right tools for the tasks, relevant knowledge and experience.

e) Efficiency

And lastly, you also need pole line accessories to enhance effectiveness. What I mean here is that depending on the particular application, it’s at times challenging to accomplish most of them without these items.

Pole line hardware

In such a manner, the performance or effectiveness of the line will be adversely affected. And what follows is poor service and complaints or dissatisfaction from the end-users. So primarily, the use of these accessories help to improve the efficiency of the application, which results in better service delivery.

Classification of Pole Line Hardware

So far we’re moving on well. And in this section, the focus is to discuss the most common categories of pole line hardware in the market. Interestingly, in as much as most of these accessories fall into different categories, you’ll find that they are applied interchangeably in most occasions. Or in some cases, they’re all used together to accomplish a particular task in an overhead line structure. So let’s describe these classifications on a one by one basis;

§ Pole Line Fasteners

This category of pole line accessories refers to the group of items commonly used for mounting wooden cross arms to poles. These fasteners are also common in mounting line construction specialty materials. They come in different sizes, designs, and shapes which is vital since it helps to match the specific application. It also allows you to have open options for the particular task you want to perform.

Pole line fastener

Pole line fastener

Some of the typical configurations of pole line fasteners include rods with threads, headed bolts, bent bolts, etc. In many instances, these fasteners often have a semi-cone point and also use square nuts and galvanized to resist corrosion and rust. Examples include brace bolts, carriage bolts, hex head bolts, oval eye bolts, straight thimble eye bolts, angle thimble eye bolts, etc.

§ Insulator Hardware

This category refers to the materials whose internal electrical charges do not necessarily flow spontaneously. Precisely, they are the types of elements that only allow a restricted amount of electric current to flow through under the electric field’s influence.

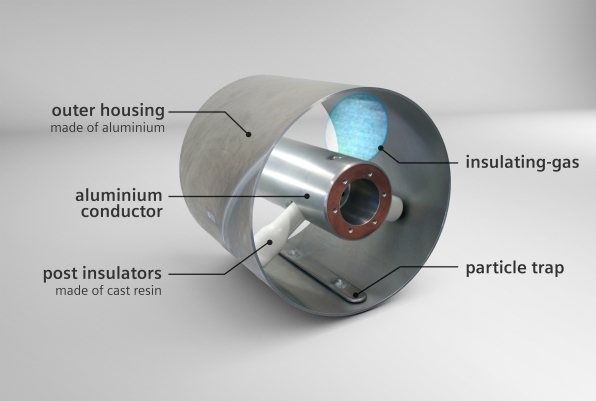

Gas insulated transmission line – Photo courtesy: SIEMENS

Better still in layman’s language, they are types of materials that do not conduct electricity efficiently. Some would refer to them as poor conductors of heat or electricity. Pole line insulator hardware comes in different types, sizes, designs, and importantly, materials. Typical materials include porcelain, plastic, rubber, and glass, among others. Examples of pole line insulator hardware include clevises, spool bolts, line post studs, cross arm pins, and porcelain knobs among others.

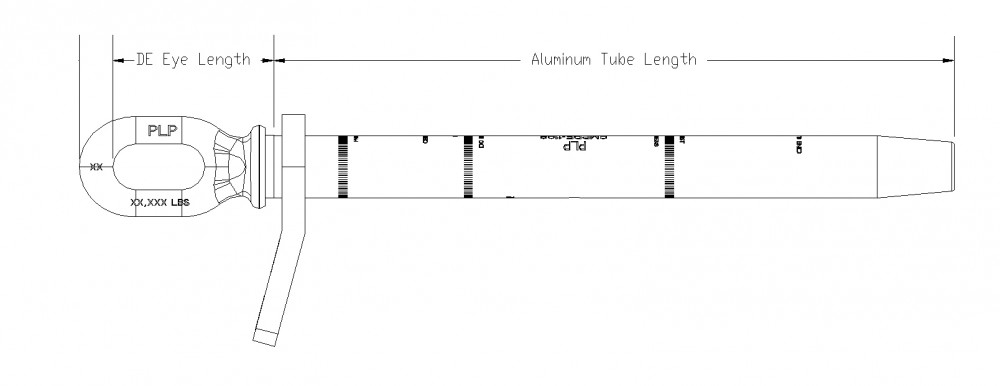

§ Dead-end Hardware

This category refers to the types of pole line hardware which do not allow live current to pass through or beyond that point. Necessarily, the design of this equipment is to prevent the transmission of a current or similar element from going beyond it.

Dead end hardware

In the pole line structure, the dead-end hardware is seemingly ordinary and widely used in various applications. Of course, they also vary in size, design, shape as well as material. They’re also significant in providing the necessary amount of tension, especially in large industrial applications. Examples include clamps, insulators, hooks, pins, shackles, eyelets, rope clips, and rope thimbles, among others.

§ Tower Hardware

These refer to the types of hardware that you commonly use for holding and tightening different components of overhead line structures. Mostly, the use of tower hardware is common, especially in fixing and supporting the components at the highest point of the poles. They’re vital since they help to support even heavy parts rendering them safe and enhancing the efficiency of the overall structure.

Tower hardware

Some of the common ones include socket eyes, thimble clevis, turnbuckles, and ball clevis among others. The materials for manufacturing the tower hardware also vary, and the use of each is dependent on the specific application.

§ Drop Hardware

The drop utility pole hardware refers to the items designed for keeping your aerial installation secure and safe. They essentially hold the relevant components in an ideal position hence preventing loose connectivity that might result in danger or inefficiency.

Clamp

The aerial drop hardware comes in various forms, and some of them include wire clips, drop wire clamps and span clamps. Also, the house brackets, cable clips, staple and steel banding are the other types of common drop utility pole line hardware materials.

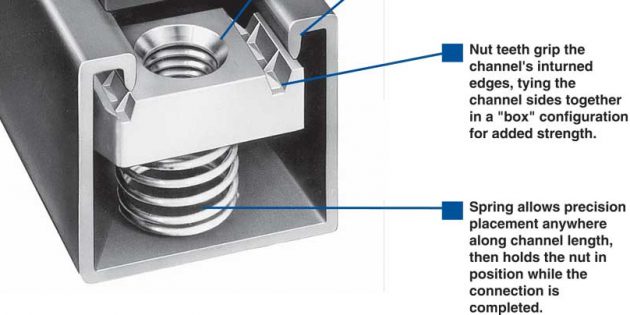

§ Strut System Hardware

It is the category that functions in the form of a suspension in the overhead line structure. The strut system consists of various components that also play a fundamental role in accomplishing the effectiveness of a particular application. Some of the strut system hardware can be quite small, but they still play integral roles in the entire overhead line mechanism. Examples of some of these components include channel nuts with springs, channel nuts without springs, and combo nut washers.

Channel nuts

Also, stud nuts with springs, without springs, and channel nuts with plastic cups and studs are among the strut system hardware.

§ Quick Release Pins

Also, a common category of utility pole line hardware these items firmly help in aligning and fastening two applications. What happens when using these pins is that once you insert them into a particular application, it becomes difficult to remove them. Incidentally, it’s only removable upon depressing a button on top of the T handle or sunken grip.

Quick release pin

These products are available in different sizes, lengths, and also designs. So it becomes easy for you to merely choose the appropriate one accordingly.

§ Distribution Hardware

Now, there are common types of hardware applicable in a wide range of overhead structures for transmission systems. They’re specifically designed to assist in enhancing the transmission of various elements from one point to another. These items could be as many as possible in a particular transmission system, but they all play unique roles in every application.

Transmission line

Some of the widely used types of distribution hardware include cut out arrestor brackets, strain yokes, and transformer mounting. Significantly, those are the key categories and examples of utility pole line hardware. However, you should always have in mind that there could be more depending on the type of overhead line structure.

Transformer mounting

The bottom line here, nonetheless, is that the uses of these accessories are unique. Therefore, you got to ensure you make the right selection for the right task.

Key Considerations when Buying Suitable Pole Line Hardware

As we move to this point, the primary emphasis that I’d like to put across is that this hardware is nowadays all over the market. You can simply get online and make your order from a particular online store, and within a short period, you’ll have it. Alternatively, you can get to a physical vendor and make your selection of the actual pole line accessories then leave with them. But tentatively, something that should always cross your mind is the fact that not all these pole line accessories are suitable for your needs. It thus implies that you have to figure out appropriately and identify the particular properties which you require from a certain accessory. For that reason, let me take you some of the general factors that you should look into when buying a fitting pole line hardware;

I. Type of Material

Without mincing words, this is arguably the most significant factor to consider when looking for a suitable pole cable accessory. You see, all these accessories are made of a wide range of materials including steel, plastic, rubber, and glass, among others.

Cross arm made from steel

Cross arm made from steel

Therefore, when purchasing, it is indeed ideal for determining the type of material that the item is manufactured with. Also, you need to figure out whether or not that type of material befits the purpose of the hardware in discharging its duties.

II. Design of the Accessory

When I talk of the design, I also mean the shape, size, diameter, finishing, and color of the hardware if any. What happens is that some pole line accessory manufacturers often use this factor to gain leverage in the market. So they manufacture the products with different or unique designs to stand out and attract users in various ways.

Different designs of socket clevis

Well, this could be an added advantage to some extent, but the bigger picture is whether it affects performance and efficiency. And while you’d be thinking of buying a particular accessory due to its design also consider knowing whether the design improves effectiveness. Furthermore, you must also ensure that irrespective of the design it has to fit and conform to the necessary standards.

III. Safety Rating

When selecting suitable pole line hardware, safety ought to be a top priority. Remember, this is an item you’re using to construct or fix a component that many people and properties will be using. So first it’s of utter essentiality to safeguard these lives and properties before anything else. This is to means that you must find out how many accidents have been as a result of that particular model prior to if nay. For the likes of the distribution pole line hardware, you must also establish safety measures that they provide before purchasing. And finally, you have to ensure that they meet the regulator’s safety standards before purchasing.

In fact, a suitable brand shall always make sure that it goes above and beyond to put all integral safety measures in place. If you’re a novice in this sector, you might as well consider getting assistance from an expert who understands the aspects.

IV. Type of Application

So far, I’ve spoken about the type of application quite broadly, but I am still emphasizing the same regarding selection. You see, the design for this hardware is specifically for particular applications. Of course, there are a few exceptions where some apply to different uses. But even though you have to verify their suitability in each and whether they have any effect on performance.

Pole line hardware for different applications

Essentially, determining the type of application is an ideal way of ensuring that you’re selecting the right pole line hardware for the task. It is incidentally the typical way of attaining the best accessory that guarantees performance, efficiency, and convenience.

V. Resistance to Various Conditions

Ideally, all the pole line hardware is fixed in a manner that exposes them to a wide range of environmental and physical conditions. What I mean here is that even the ones in some form of enclosures are still put outside where weather conditions can be unfavorable. And it’s for that reason that you need to ensure you go for a pole line accessory that has ultimate resistance to such conditions.

The electrical transmission line in the sea

Corrosion and rust are some of the major weather conditions that often affect the suitability of this type of product. Also, they have to be durable in the sense that irrespective of the extent of unfavorable conditions, they could still endure and perform excellently. And for that reason, it’s always advisable to go for reputable brands that have stood the test in the market.

VI. Cost of Buying

Well, this is the other relatively sensitive element that you need to consider when purchasing these items. On many occasions, you’ll find that the pricing of a particular accessory varies from one dealer to another vendor. Significantly, the cost of buying different models also depends and it’s the reason you need to determine your budget first. And if you want a better deal, especially when buying these items in bulk, it’s recommendable to do a broader search before settling on one. This way, you’ll have to choose the one that suits your budget and the quality standards that you require. And talking of quality, let us now find out the type of materials you’d necessarily go for in choosing pole line hardware.

Pole Line Hardware Materials

What usually happens is that manufacturers understand the particular requirement for specific pole line hardware. And that is the reason you’ll find materials for such components vary depending on a number of factors. Remember earlier on I’d state that the type of material for the hardware is unquestionably a significant factor to consider. In line with this, you have to understand that manufacturers often use several types of material to create these products. Some of the conventional materials for manufacturing pole cable accessories include the following;

§ Carbon Steel

This is apparently the highest rated material for producing various types of pole line accessories. It is essentially an alloy of carbon and iron or better still you refer to it as steel with carbon content. This material is vital for manufacturing various forms of pole line hardware as it contains some suitable properties. One is that carbon steel is hardy and resistant to numerous environmental aspects, including harsh weather, rust, and corrosion. For a fact, carbon steel becomes even harder and stronger when subjected to heating, which arguably makes it the best option for these applications. The good thing carbon steel is an ideal material for such hardware because it’s available in a variety of qualities. Now this means that you can find it in lower, medium, and higher qualities. So what this translates to is that the steel becomes more brittle and stronger if it contains more carbon. Again, it’s an indication that you can regulate the level of carbon to use in manufacturing a certain part of the pole line accessory.

Steel electrical cross arm

Steel electrical cross arm

This material is utterly suitable for most robust utility pole line hardware, especially those that hold heavy loads. It follows that carbon steel hardly breaks or becomes weak, so that’s a considerable property making it suitable for utility pole line hardware.

Furthermore, carbon steel is also resistant to heat, corrosion, and rust. And since most of the overhead line hardware is always exposed to different conditions, it becomes a suitable material for these items. Some of the notable pole line accessories made of carbon steel include fasteners, dead-end components, towers, and aerial drop hardware. Of course, not all of these are manufactured using carbon steel material. So let’s find out some of these types of materials too.

§ Polycarbonate

This is also the common material common for manufacturing different types of pole line hardware. You see, one underlying factor of any material befitting pole cable accessory is that it has to be resistant to various adverse conditions. And polycarbonate is one of these materials that will never let you down when it comes to high resistance and durability.

Insulators are the common hardware that widely uses polycarbonate material. Also, some components such as pole line electrical enclosures like the meter box and similar parts are also conventional with polycarbonate. In other instances still in pole line hardware, polycarbonate is used in making dead-end equipment and many more.

§ Aluminum

Aluminum

Aluminium is the other suitable material for manufacturing this type of hardware. This metal is light, durable and functional, making it one of the key materials for manufacturing various types of pole cable accessories. If you’re keen enough, you’ll notice that other than carbon steel, most of the hardware for overhead line structures is made of aluminium. Some of them include lashing clamps, cable lashes, suspension clamps, tap brackets, cable straps, cable dampers, and clevis, among others. It is also reliable, strong, and stable making it an ideal choice for manufacturing these types of hardware.

Evidently, you’ll find some parts made from other relatively unknown materials. However, you should always ensure that such materials meet the necessary standards, especially from the perspective of safety. Right now, though, we want to move a step further in this guide to find out some of the various types of the pole line hardware.

Types of Pole Line Hardware

In this guide so far, it’s quite clear that indeed several varieties of this equipment are available on the market. The most important thing that you, however, need to do is identify the particular type that you require for your specific needs. Of course, we can’t necessarily discuss all the types of pole line hardware available today because they are in the hundreds. Nevertheless, let’s describe a few key ones that you’re likely to need or come across;

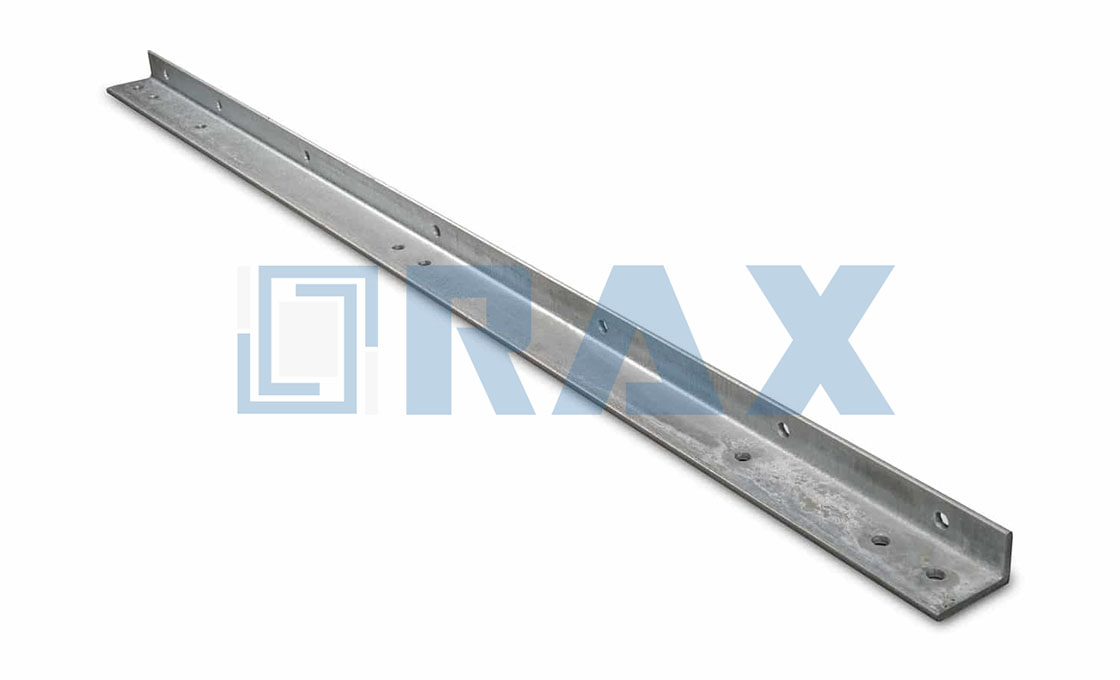

1. Steel Cross Arm

It refers to an engineered piece of composite equipment mounted on an overhead line pole to hold the electrical components or power lines. It is an essential component since it helps in anchoring and supporting the conductor along with the overhead line infrastructures.

Steel cross arm

Steel cross arm

This type of cross arm is often reliable, strong, and durable hence ideal for both new installations and replacement of aging utility equipment.

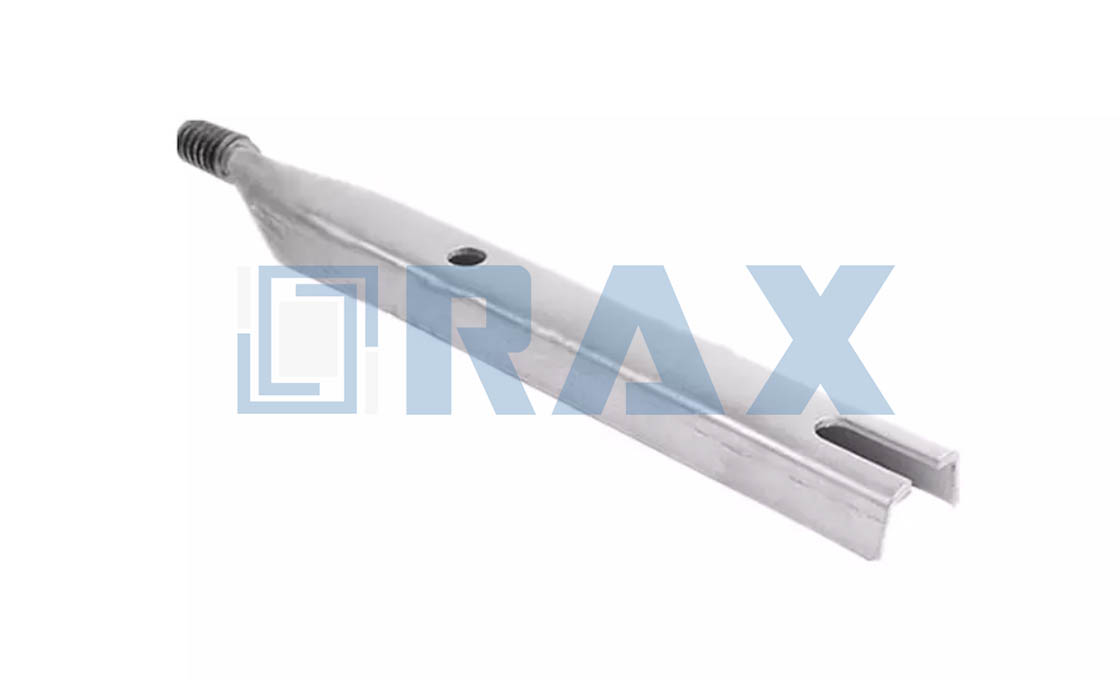

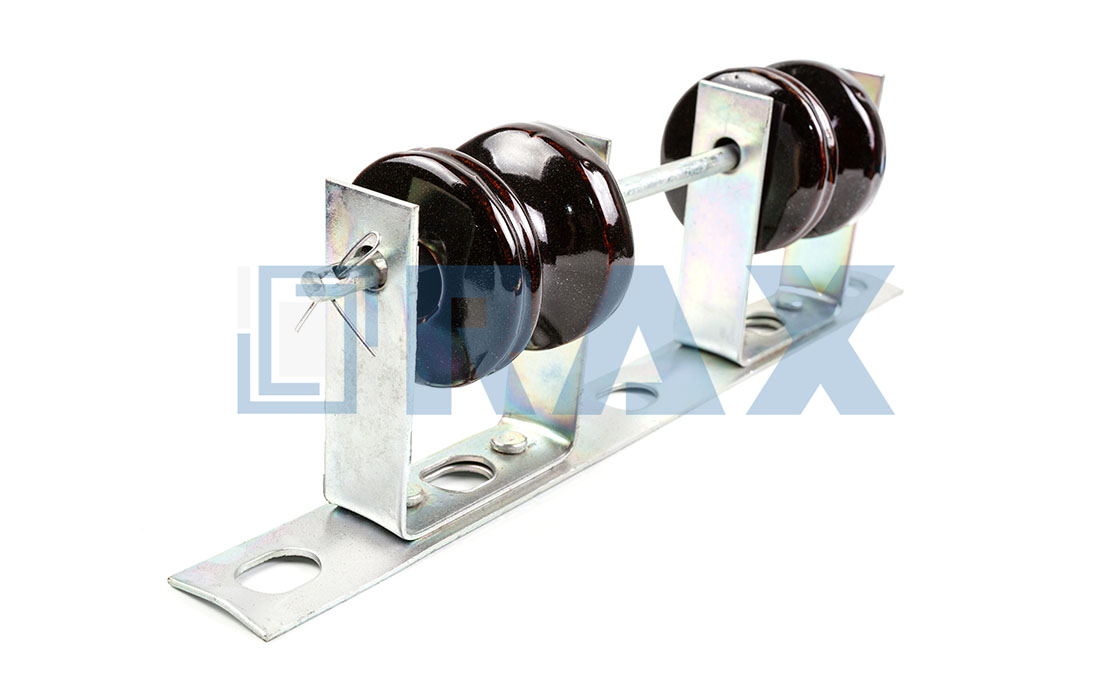

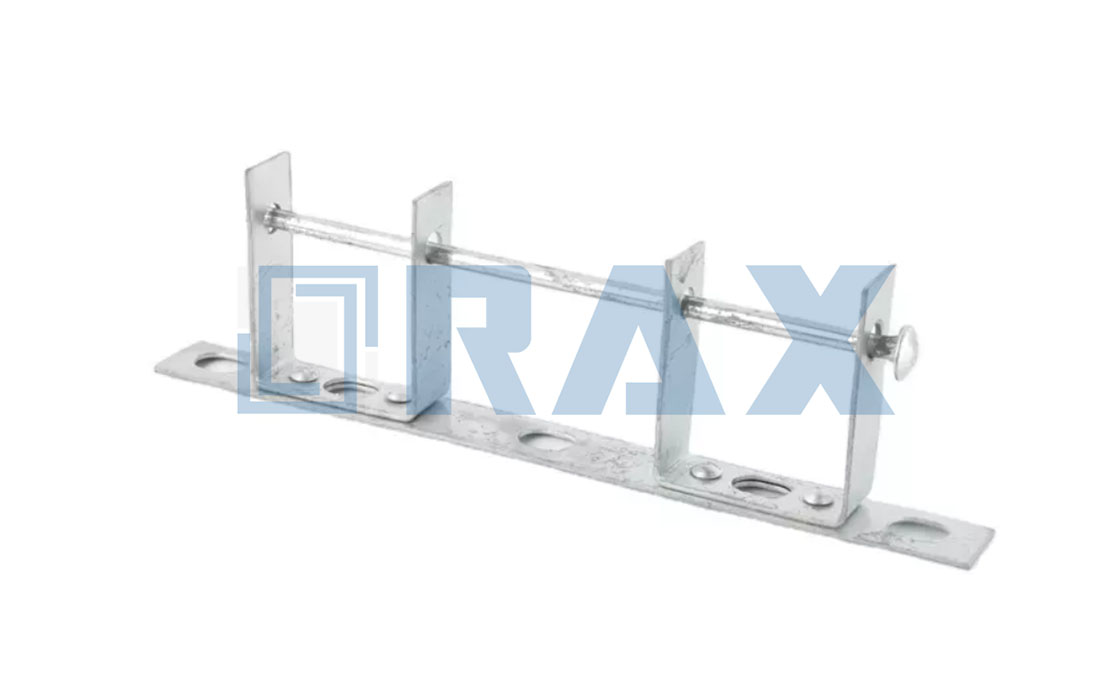

2. Secondary Rack

It is the component mounted on a pole line for stringing the secondary conductors. They come in different sizes that would be able to accommodate two to four conductors.

Secondary rack

Secondary rack

It is mounted on the pole by fastening it using lag bolts on a straight line.

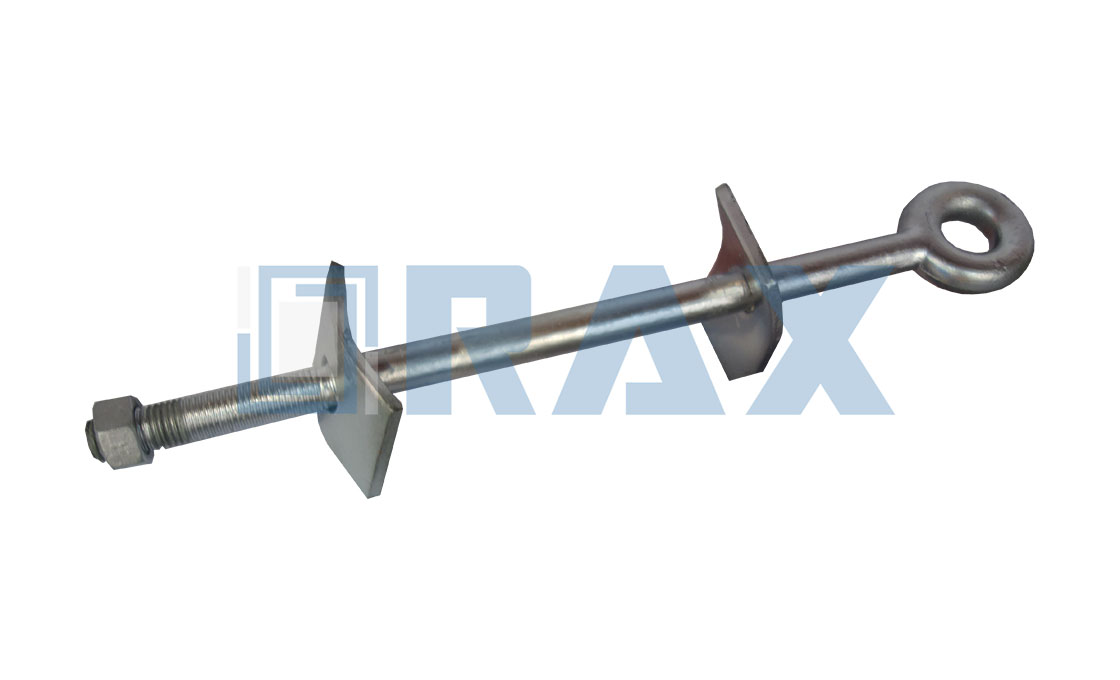

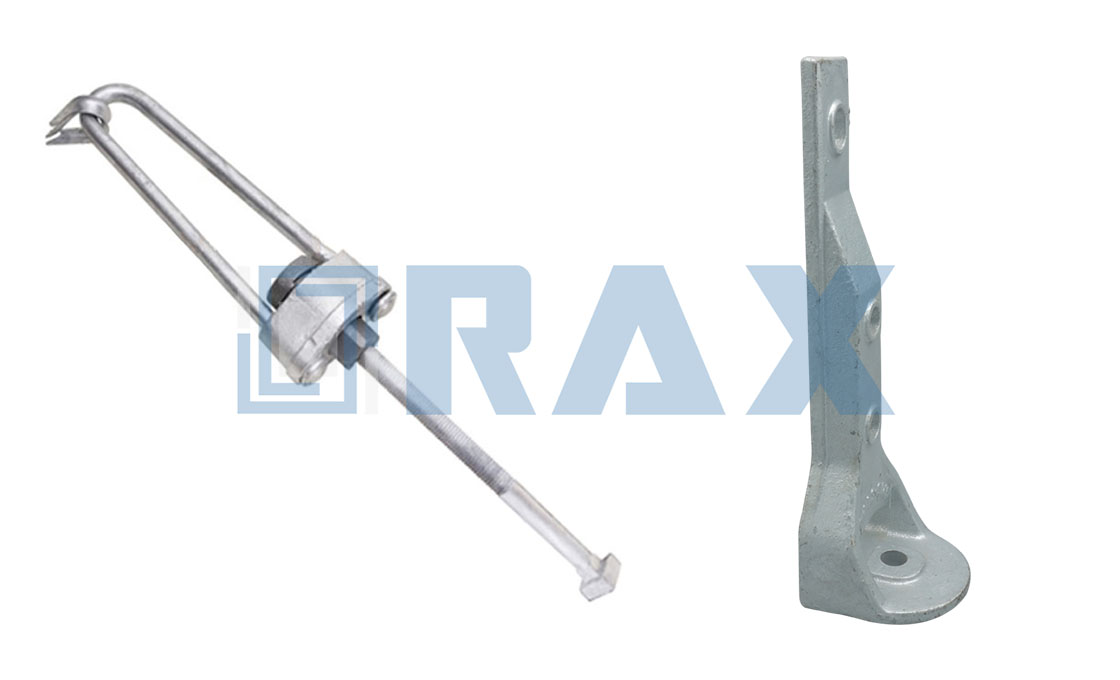

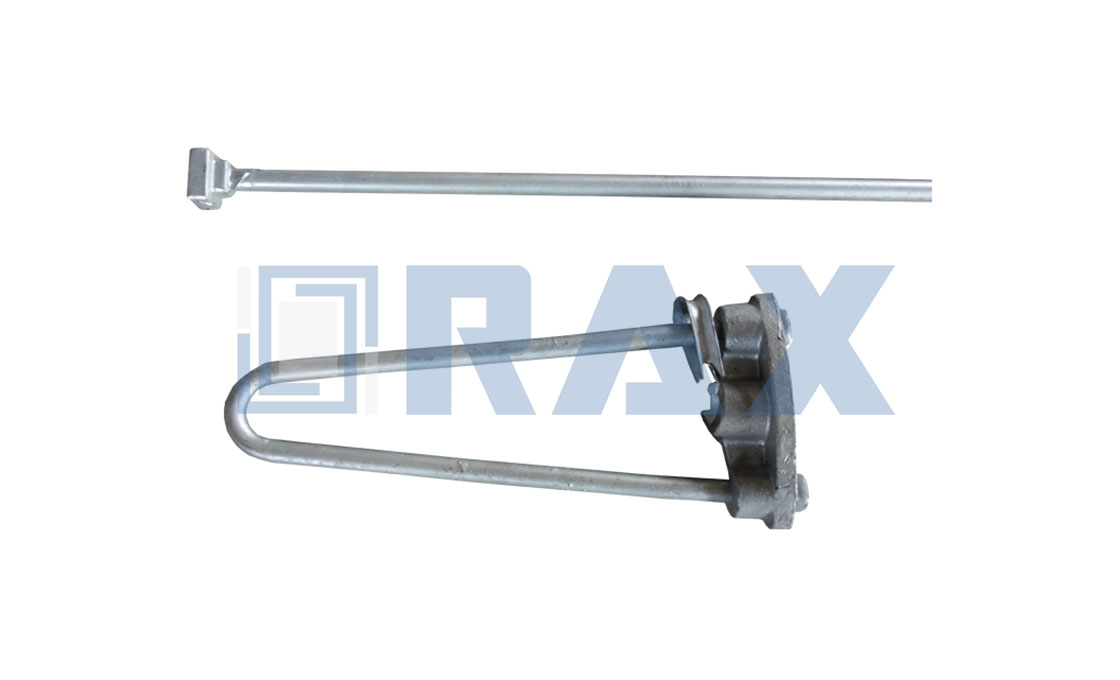

3. Stay Rod

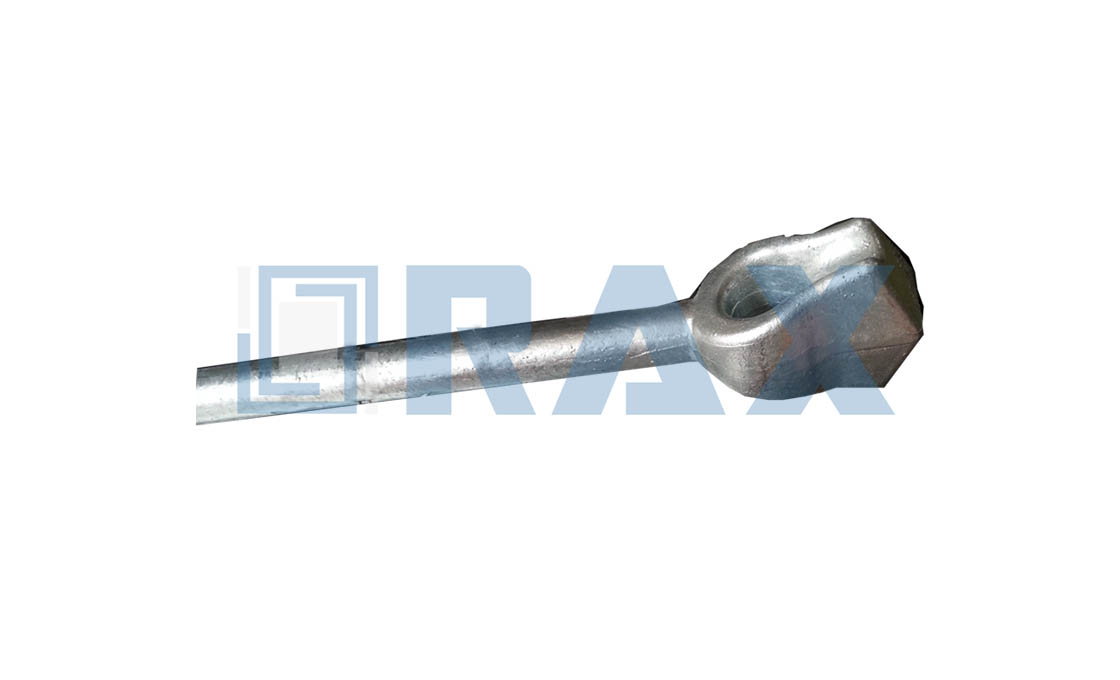

It refers to a galvanized steel rod that is used for connecting the stay wire to the ground anchor.

Stay rod

Stay rod

It is available in different types, sizes, designs, and lengths and may or may not come already fitted with thimble eye nuts and washers.

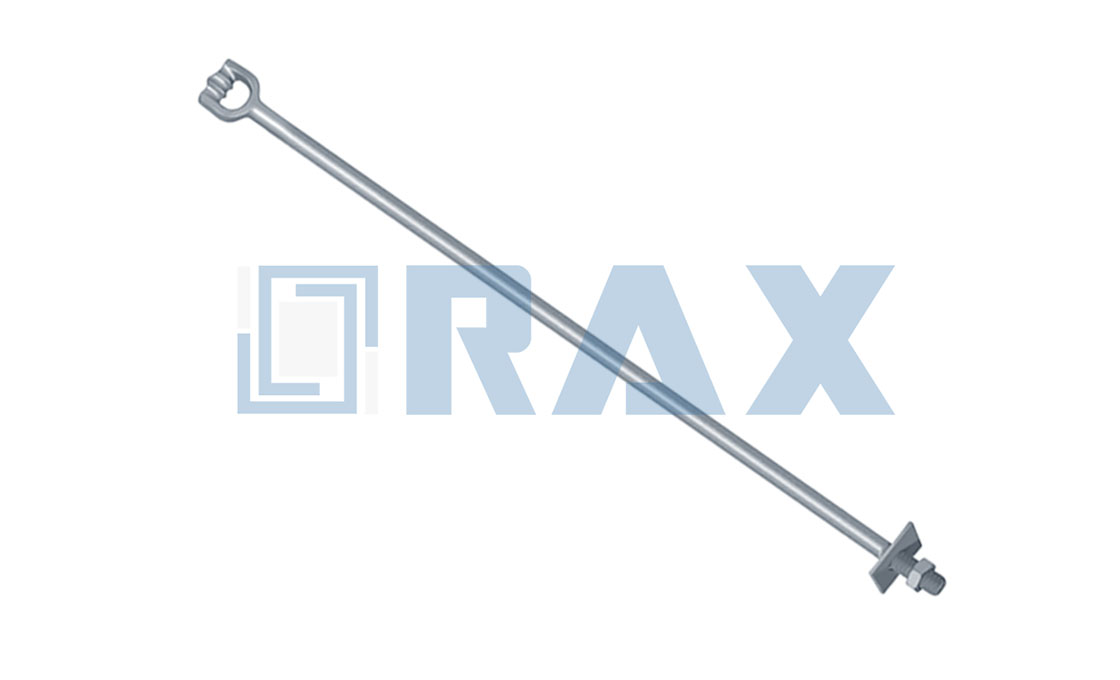

4. Anchor Rod

This is a rod or bolt embedded in concrete foundations to provide support to the pole line infrastructure and many other applications.

Anchor rod

Anchor rod

It has quite a lot of names that you may at times choose to refer to it such as foundation rods, concrete embed, and anchor bolts among others.

5. Guy Thimble

This refers to a galvanized curved metallic object used on the pole band to provide an interface fitting to connect the guy wire.

Guy thimble

Guy thimble

In most instances, this component is applicable to transmission lines or dead-end pole lines. It ordinarily connects with a preformed tension clamp as a way of supporting and protecting relevant cables.

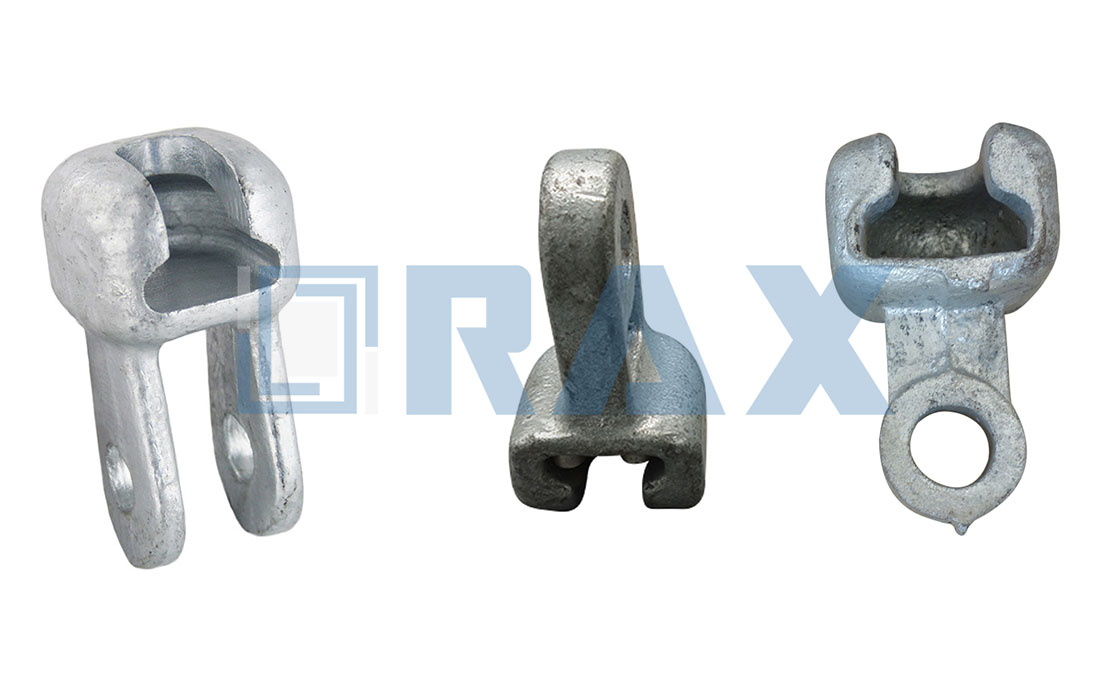

6. Ball Clevis

These refer to the type of pole line accessory commonly used for attaching ball and socket insulators to other associated tower hardware.

Ball clevis

Ball clevis

They are often made of galvanized steel and also come in different sizes depending on a specific application.

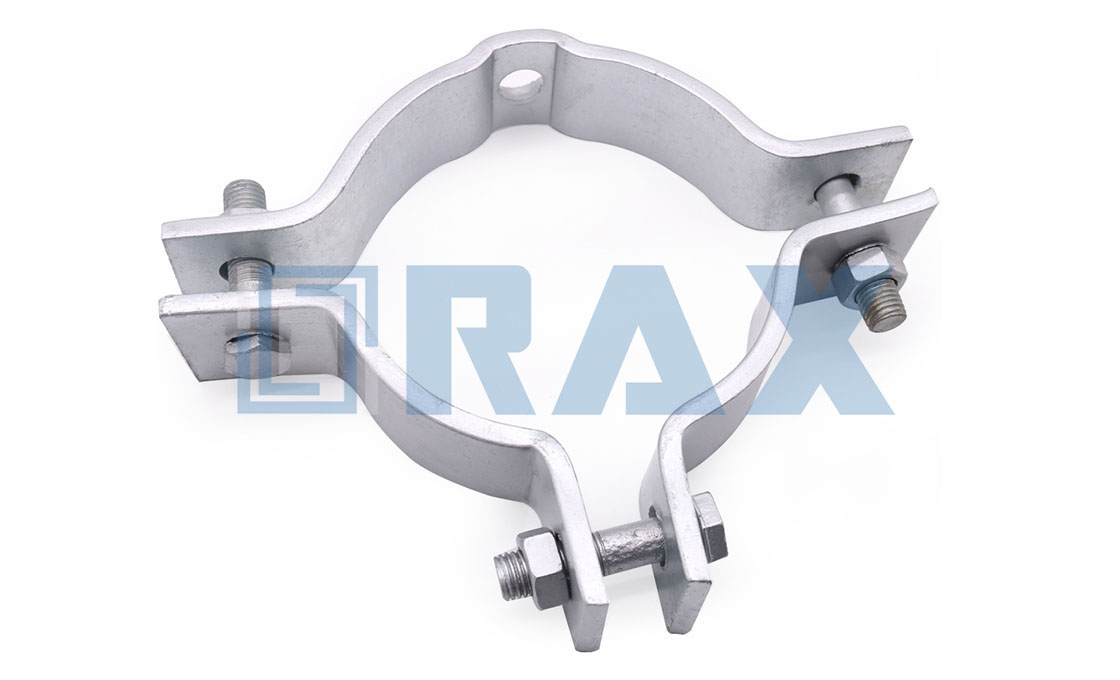

7. Guy Clamp

It is a component with straight parallel grooves used in pole line structure to hold or secure the ends of the guy strand wires.

Guy clamp

Guy clamp

In most instances, whenever you order this part, it comes already with bolts assembled. Most of them feature clamping bolts with an oval shoulder to prevent turning during tightening.

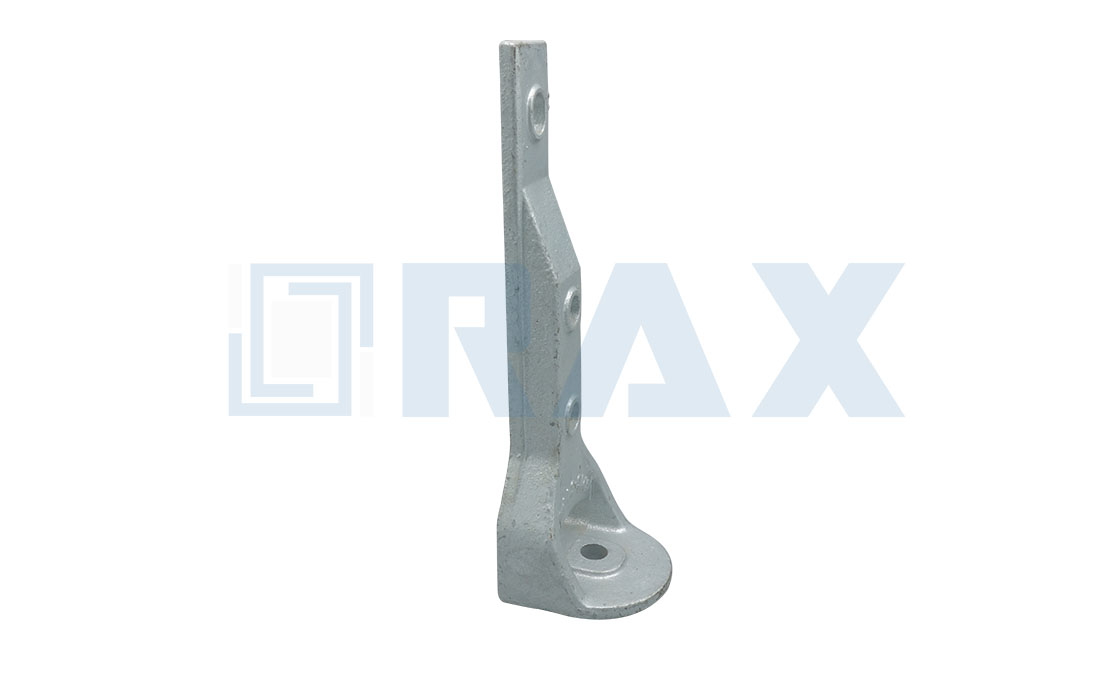

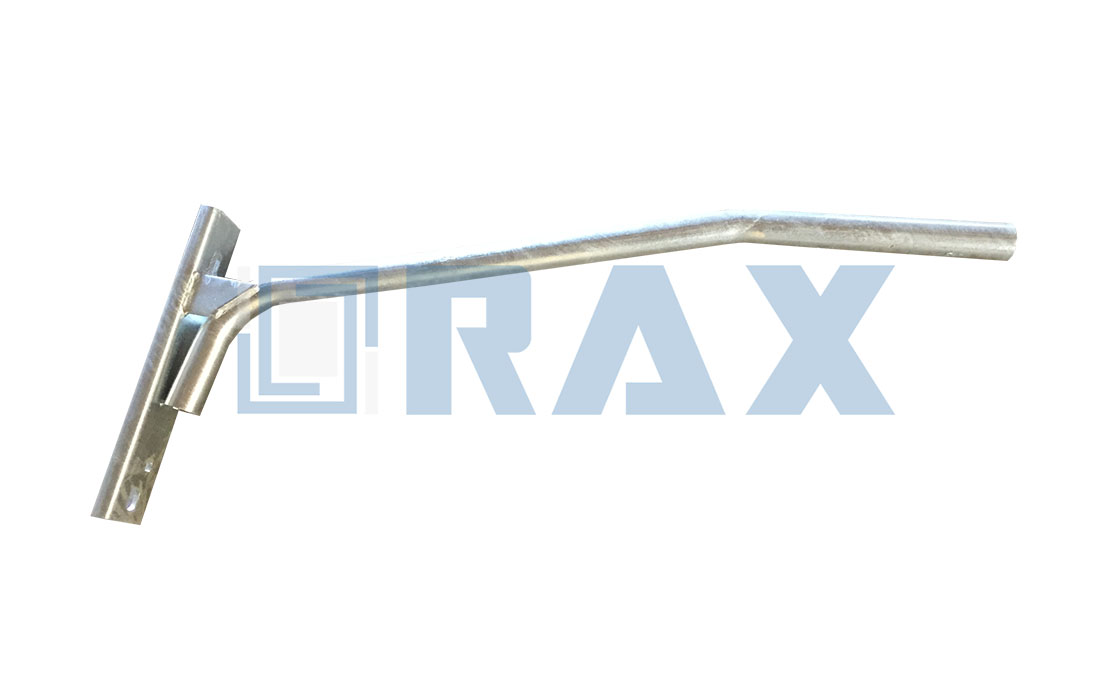

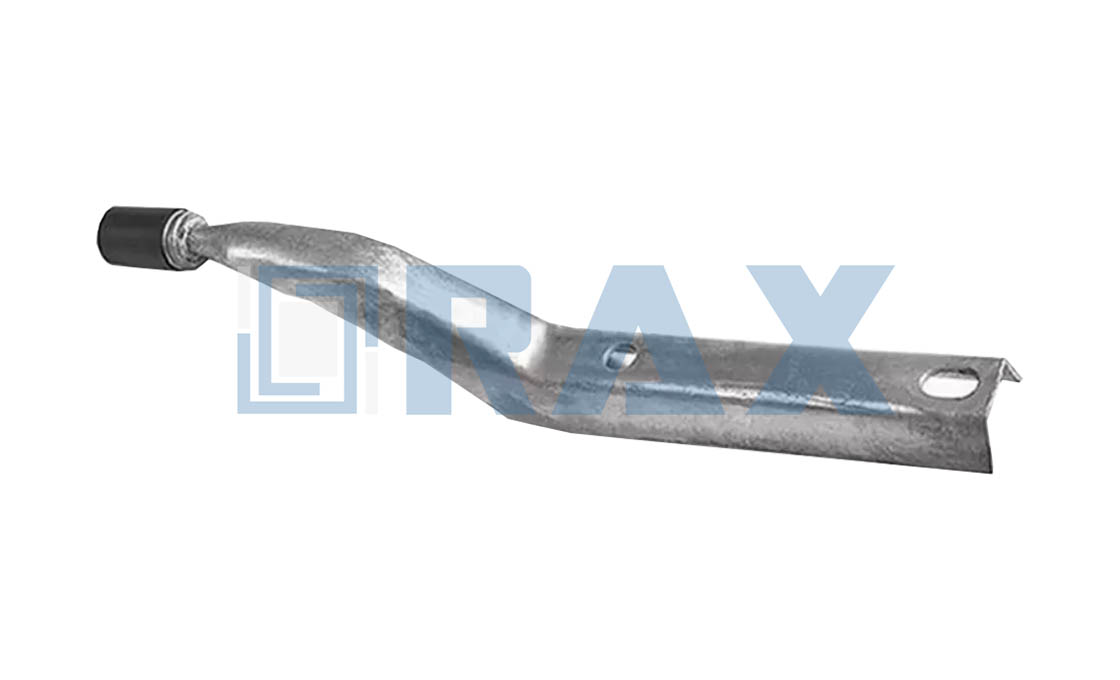

8. Pole Top Bracket

It refers to pole line hardware used for mounting insulators and provides a bigger distance in separating the middle phase.

Pole top bracket

Pole top bracket

This equipment is also common for anchoring post insulators on top of overhead line structures.

9. Pole Top Pin

This refers to a device that you use to support overhead electrical conductors on poles.

Pole top pin

Pole top pin

But notably, the pole top pin supports an insulator pin adapted for attachment on top of the pole.

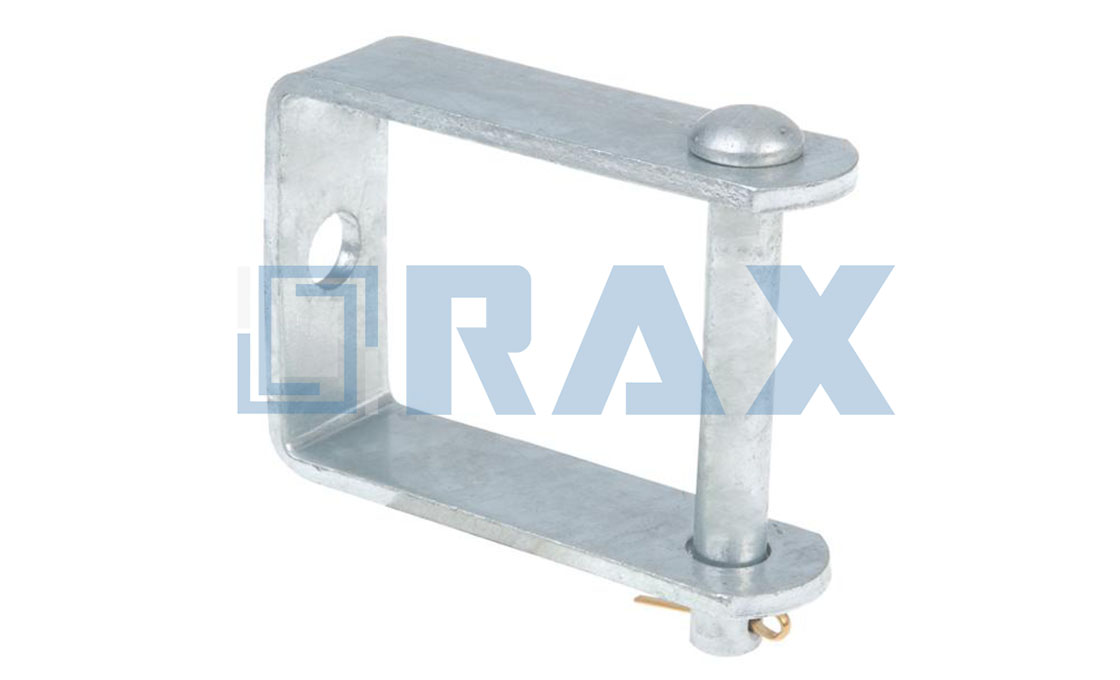

10. Secondary Clevis

It refers to a U-shaped three-piece fastener system that consists of a clevis, pin, and tang.

Secondary clevis

Secondary clevis

It is common in secondary low voltage lines where the secondary racks limit the necessary spacing.

11. Socket Clevis

This is a component used to connect associated hardware to the ball and socket-type insulators.

Socket clevis

Socket clevis

12. Yoke Plate

This is a special fitting designed for attaching a number of insulator strings or other types of parallel elements.

Yoke plate

Yoke plate

So essentially, these are some of the common types of pole line hardware that you’ll come across in most cases in various applications. Definitely, other hundreds of these accessories are also available in the market. So you’ll get to know them more as you continue using such accessories in varied applications. And talking of varied applications, we’ve seen how different pole line hardware plays various roles in a number of applications. So, it would be prudent to now look into these applications in detail to find out more about how they relate to these components. Let’s find out more regarding the same in the next section.

Applications of Pole Line Hardware

Like it is apparent that the types of pole line hardware vary, that’s how the installation process for each type also varies. For that reason, it would be ideal to know the right type of this pole line accessory to use in a particular application. But in general, you can find them applicable to most of the aerial overhead line constructions including the following;

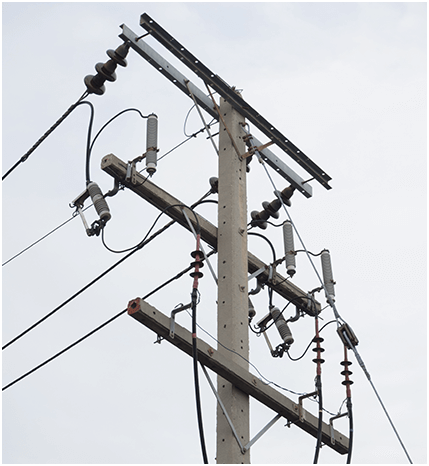

§ Transmission Line

It refers to a specific system of structures, insulators, wires, and various hardcore accessories which carry and relays electricity from one point to another.

Power transmission line

Typically, these types of lines operate at a comparatively high voltage and have the ability to transmit electricity over long distances. Clearly, a transmission line uses quite a number of pole line hardware. It follows that connection of several components of this particular unit call for the use of different hardware. The hardware applicable in a system line is ordinarily made from a wide range of materials, commonly conductors. But you might as well find other non-conducting pole line accessories made of polycarbonate or mere plastic among others. For instance, the meter enclosure and yoke plates, among others. But the most important thing, however, is to make sure that any particular hardware you purchase, has to fit appropriately.

§ Telephone Pole Line

This is also the other type of application where the use of pole line hardware is seemingly common. It is basically an overhead line that hosts a wide range of telephone communication parts, equipment, and components. So what happens is that several types of accessories are used in anchoring, holding, and fastening these parts and components.

Telephone pole line

The good thing is that most of this hardware is easily obtainable as long as you know the precise type that you need. However, the types of telephone pole lines may, at times, vary depending on various factors. In this case, it implies that you’ll need to have a particular type of hardware and install it accordingly. The most important thing regarding this application is finding the specific type of hardware that enhances performance and efficiency.

§ Utility Pole Mounting Line

This refers to a type of post or column that supports overhead power lines and a wide range of public utilities. Some of these public utilities may include fiber optic cable, electrical cables, and other components like transformers and street lights among others.

Utility pole line

This type of pole is inherently multipurpose and can be used in supporting several overhead lines simultaneously. But the primary purpose of this type of pole is to carry different kinds of electric lines and sub-transmission lines.

For that reason, it’s quite evident that this type of mounting line uses a number of pole cable hardware. Because for one, you have to ensure that all the overhead cables serving different purposes are insulated. In fact, this is the ideal way of preventing them from messing up and causing danger to different users and properties.

The good thing, however, is that hardware for utility mounting lines can be made from different types of materials. So in many instances, you’ll find that various materials including fiber, glass, metals, and plastics, among others, make up some of this hardware. Therefore, it is fundamentally the nature of the purpose that this type of pole serves, which makes it somewhat necessary to incorporate various accessories.

The essentiality of this hardware is to provide safety and efficiency for the different services that the utility poles offer. Well, these are the basic and common applications of various pole line hardware. At times you may also find that some of these accessories are used even in underground line structures.

Installing a Pole Line Hardware

Now, this is one of the most sensitive aspects concerning pole line hardware. By the way, identifying and purchasing them also requires knowledge, but installation is what ultimately matters. You see, the many times that the installation of this hardware takes place, you’ll always find a group of engineers on site.

Well, it’s an indication of how much expertise is necessary for carrying out the task. So in simple terms, what I’m trying to say here is that first before you think of installing these pole line accessories, ensure that you have the relevant knowledge. You must also make sure that you have all the right tools and equipment for doing the job as a way of improving efficiency.

Now let me give you a few ideas for installing these components on overhead line infrastructures. First, it depends on whether this set up is for the new system, repair, or replacement. These are basically what determines the installation process. But for the sake of all of these perspectives, let’s start with a general installation of a new overhead line structure.

i. Site Clearing and Preparation

The moment the project obtains all the relevant permits, the construction crew begins to clear and prepare the site accordingly. The extent of clearance will depend on the nature of the site. If it requires much detail, then the task will also be thorough. What you should give importance, in this case, is ensuring that the vegetation around won’t grow later to interfere with the line.

During preparation, a fundamental element to always consider is the accessibility of the site. Make sure that machinery and other heavy equipment can get access to the site if necessary. Remember you’ll be using vehicles to carry most of these pole line hardware to the site since they’re seemingly heavy.

ii. Installing the Structure Foundation

The next step in this process is drilling the foundation for the new infrastructure. It merely involves drilling holes, which then you fill using concrete to form formidable foundations. Once the drilling of the holes is complete, the steel bars are placed in every hole then the holes are filled with concrete.

iii. Fixing New Structure

Once you’re done with curing the foundation, you can then begin to install the transmission structure. Remember it is this structure that will enable you to fix all the relevant pole line hardware upon erecting it. So you have to ensure that you get every bit of its installation right to prevent unnecessary inconveniences later on.

If the poles or steels are relatively heavy, you can opt to use cranes to lift them as the fastening of the same continues. If you have all the materials readily available, fixing and erecting the new overhead structure may take at most three days.

iv. Stringing of Pole Line Hardware

Now, this is the point where you’ll have to start fixing all the compatible pole cable accessories accordingly. You have to be keen on whatever connection you make here because it is the ultimate stage that defines the entire process and functionality.

Of course, the engineers on-site have testing devices for determining whether all the stringing of cables is rightfully done. And of course, there is also a manual for installing particular hardware in this structure. Always ensure that you have all the relevant tools and equipment that would allow you to install these accessories well. And once every component is in place, you can then choose to carry out a test to determine whether or not everything is alright.

v. Set the Line ON

At this stage, you have finished the installation. What you do now is primarily setting it on so that it can serve the users, respectively. And it is that simple. However, if you want to replace or repair the pole cable accessory, you’d start at step 4. It would be mainly about establishing the right pole line hardware and using the right tools to replace and repair them. So it’s basically what you require to do in installing these items. The most important thing that you need to do is to ensure your safety and that of your surroundings. Therefore, always take safety precautions at all times whenever you’re engaging in any activity regarding the installation of pole line hardware.

Rax Industry: Your Premier Pole Line Hardware Manufacturer for Industrial Applications

So far we’ve seen that pole line hardware are critical components to both humans and properties in addition to providing efficiency.

It, therefore, implies that they are not an ordinary thing to gamble with, especially when it comes to purchasing them. Primarily, what I’m saying here is that you have to be curious about the brand if any overhead line accessory you’re buying in the market. You need a reputable manufacturer with a brand name that has stood the test of time in this sector.

Rax Industry is one of these manufacturers that you should always choose when looking for these items. With the experience and expertise of this manufacturer in this industry; it’s arguably the best you can ever find in the market.

This company manufactures all sorts of pole line accessories that you would need for various applications, whether residential or industrial. What’s more, is that the quality of their products is also above reproach. So if you’re looking for the best deal worth your investment, then definitely consider Rax Industry.

The primary process of making the pole line hardware is as below :

All Rax Industry Pole Line Hardware is hot-dip galvanized after all sawing, shearing, drilling, punching, filing, bending, and machining are completed.

Hot-dip galvanizing

The pole line hardware hot-dip galvanizing is following ISO1461 and is applied by the hot-dip process to provide a thickness of zinc coating of not less than 610gm of zinc per square meter of the surface on steel bars, plates, sections, and fittings.

Threaded work shall have a coating weight of 305gm of zinc per square meter. This way, all the pole hardware surfaces won’t get rusty. All cover is smooth, clean, of uniform thickness, and free from defects.

The preparation for galvanizing and the galvanizing itself will not adversely affect the mechanical properties of the coated material. And the lifetime of line hardware will last more than 20 years.

Rax Industry artistry is the first-class quality among so many competitors. Rax Industry workers have done very well on electric welding.

Now let’s explain how Rax Industry workers do the electric welding step by step :

1) Pole line hardware electric welding first step control: Preparation of base material

Pole line hardware raw material to be joined by welding will be cut accurately to size with edges flame-cut, sheared, or machined to suit the required of the welding and to allow thorough penetration and an excellent fusion of the weld the base metal.

If the pole line hardware raw material surfaces have defects such as lamination caused by shearing or flame-cut operation, that pole line hardware raw material will be collected to the disqualification area. If the material edges to be welded are rust, oil, grease, they are also selected for the disqualification area.

2)Pole line hardware electric welding second step control: Welded construction and stress relief

Rax Industry workers do the welding according to the confirmed drawing size and standards.

3)Pole line hardware electric welding third step control: acceptance of the welded structures

To guarantee the joints under the instructions given on the drawings and the soundness of the welds, Rax Industry QC inspector will check whether the dimensions are correct and no absence of distortion in the structure after the welding.

4)Pole line hardware electric welding forth step control: cleaning

The Rax Industry workers always remove all excess weld materials, slag, splatters, and flux residues. After cleaning, the workers will do the packing. The package quantity isn’t confirmed, it’s usually according to the size and weight of each pole line hardware fitting. The pole line hardware hot forged process is a little more complex.

The brief description is as below:

1)The first step is to heat the steel rod to a high temperature until it changes from black to red. At the same time, the shape of the steel rod is altered. The rod is crushed to a big red block.

2)The second step is to press the red block to a specific shape. If the line hardware can’t be a particular shape by a single pressing force, the pole hardware suppliers will press it twice continuously.

Rax Industry pole line hardware is mainly used on overhead power lines or power transmission lines. For the wooden pole, some pole hardware fittings are mounted by a screw machine. The flat and angle steel are used to support other electrical pole accessories. All the pole hardware fittings are connected by bolts nut and a washer.

Pole line hardware used on overhead power lines and communication lines is usually confused by people. How to identify the difference between the power line and the communication line?

Usually, For the power line and communication line, the pole line hardware is designed in different ways. The communication line pole is generally separated from the power line pole, but in a particular condition, there is a possibility that the power line and the communication line use the same pole. In this case, it asked to add one dead end supporting which includes stay set, stay wire, pole band, guy thimble, and guy clamp.

The pole line hardware connects ways are not firmed. For different markets, the pole line hardware is designed with different construction and various specification.

If you want to know the detailed design for each market, pls check here for the Russian market, South American Market, and South East Asia market.

Rax Industry pole line hardware is various kinds of pole hardware fittings which used to support the line. The primary raw material of the pole line hardware is carbon steel, few pole line hardware raw materials are aluminium.

Rax Industry raw material carbon steel includes flat steel, angle steel, and steel rod. Rax Industry always uses material that is new, the best of their respective kinds, and free from defects and imperfections.

When the present material is not the same standard as the customers’ requirement, Rax Industry QC inspector will indicate the equivalence between the material used and the corresponding material following the required rules in the contract.

At the same time, the Rax Industry salesman will try to get the approval of the customer before starting the manufacture of the pole line hardware products.

As the Chinese leading Pole line hardware manufacturer, Rax Industry has created many new types of utility pole parts and pole clamp hardware. Compared with other pole line hardware suppliers, the Rax Industry staff strictly controls every process.

Why did so many customers choose us?

1)With 14 years of artistry in punching, hot forged, casting, and electric welding, Rax Industry is your trusted manufacturer for power line hardware and electrical pole accessories.

2)Rax Industry has beaten its rivals by developing and supplying customized pole line hardware together with uniform quality and clear packing.

Rax Industry will supply your complete source for pole line hardware. To become the next Rax Industry pole line hardware distributor, you can contact us to talk about further cooperation possible.

3)Every pole hardware fitting is asked breaking strength. Breaking strength is the most crucial factor in the fittings application. To meet the breaking load standard, the Rax Industry QC team choose and scrutinize the raw material. And Rax Industry QC team makes a load test before each shipment.

Rax Industry QC team test the working stresses and the breaking strength is according to ISO or IEC standard. Rax Industry engineer supplied the drawings to the customer for review before the order. Rax Industry QC inspectors perform routine tests following the requirements of the specification.

To become the world’s leading pole line hardware manufacturer, Rax Industry will continue to pay attention to quality control and solve the customers’ problems. If you have any new ideas on making pole line hardware products, welcome to contact us [email protected] If you want to read Rax Industry pole line hardware catalog, you can download here.

Conclusion

Unquestionably, it is quite apparent that pole line hardware revolves around numerous aspects, some of which we haven’t looked into here. But for now, at least you have the idea of what it takes to buy and install a functional overhead line accessory that yields efficiency.

I’m hopeful that this guide has been significantly helpful to you in many ways. And for that reason, it would be prudent if you also feel free to share it on your social media handles. You know what, someone might also be looking for this kind of valuable information and you may be of considerable help too. Otherwise, if you have any questions, recommendations, or concerns, you may also feel free to contact us. For sure, we will gladly offer the necessary assistance.

Learn more:

- High Voltage Electrical Installations

- Electrical Power Line Installation and Repair

- Design of Electrical Overhead Transmission Lines

- Pole Line Hardware Catalogue

FAQ

What is pole line hardware?

Pole line hardware is a significant part of the pole line construction, it is the hardware combined to create the electrical facility setup come true, it’s likewise termed pole line accessories or pole hardware fitting.

What is the application of the pole line hardware?

It is widely used in many constructions, such as Transmission Line, Telephone Pole Line, and Utility Pole Mounting Line.

What are the types of utility pole hardware?

There are hundreds of types, here are some key ones:

- Anchor Rod

- Ball Clevis

- Guy Clamp

- Pole Top Bracket

- Secondary Clevis

- Socket Clevis

- Stay Rod

- Steel Cross Arm

What is the key consideration when choosing products?

Here are some factors that play a huge role when choosing products.

- Type of Material

- Design of the Accessory

- Safety Rating

- Type of Application

- Resistance to Various Conditions

- Cost of Buying

Q1: Are you a manufacturer or trading company?

A: We are a pole line hardware manufacturer with 14 years of experience.

Q2: Do you have a pole line hardware catalog?

A: Yes, If you need Rax Industry utility pole hardware catalog, pls contact [email protected]

Q3: Do you have utility pole hardware distributors in South America?

A: Yes, you can be our next distributor.

Q4: Do you have a utility pole hardware diagram?

A: Yes, you can download the utility pole hardware diagram here

Q6: What’s the pole line hardware test standard?

A: The test standards are not the same based on a different market.

Q7: What’s the MOQ for pole line hardware?

A: Generally the MOQ is 500pcs.

Q8: Can I have a sample order?

A: Yes, we can provide a sample for free, the delivery cost is usually paid by the customer.

Q9: What are the payment terms?

A: The payment is usually T/T 30% as advance payment and 70% T/T before sending the product.

Q10: Will you charge for the tooling if you do the customized utility pole hardware?

A: The tooling is usually paid by the customer, but if the order quantity is more than 5000pcs, the tooling cost will be refunded when confirming the order.

Q11: Can you send us a price list for all types of pole line hardware?

A: There are many customized types, so the price is always changing based on raw materials and different customer requirements. It’s better to give us a general description of your requirements and you will get the best schedule.

Q12: What’s your delivery time?

A: The delivery time for 10000pcs of utility pole hardware is usually 3 weeks. Pls, contact us, if you need an urgent order. We will supply a solution for you.