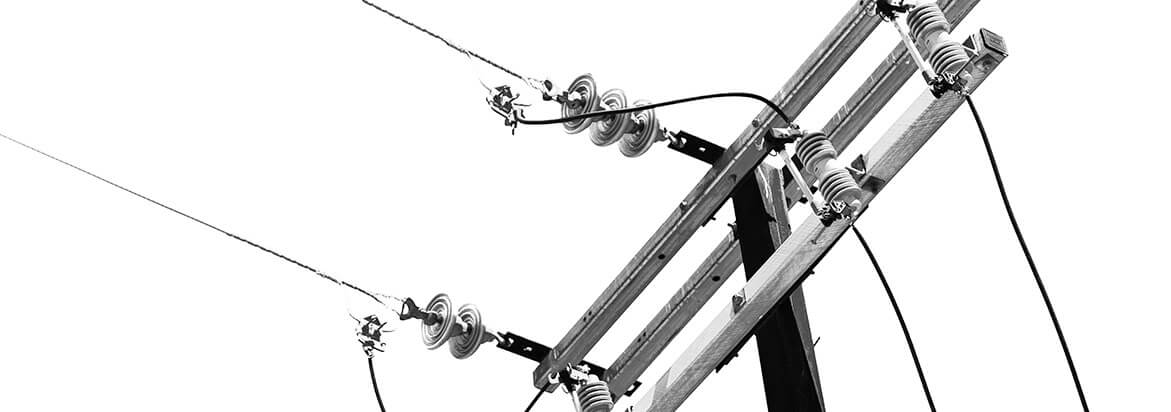

Reliable Pole Line Hardware, Reliable Cooperation

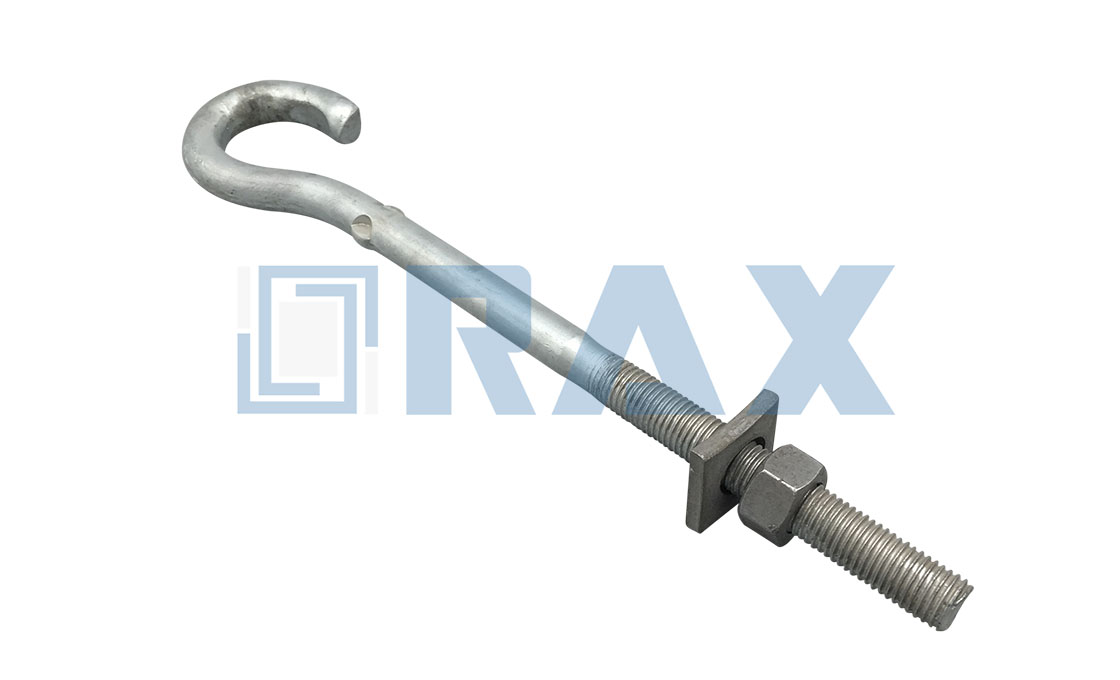

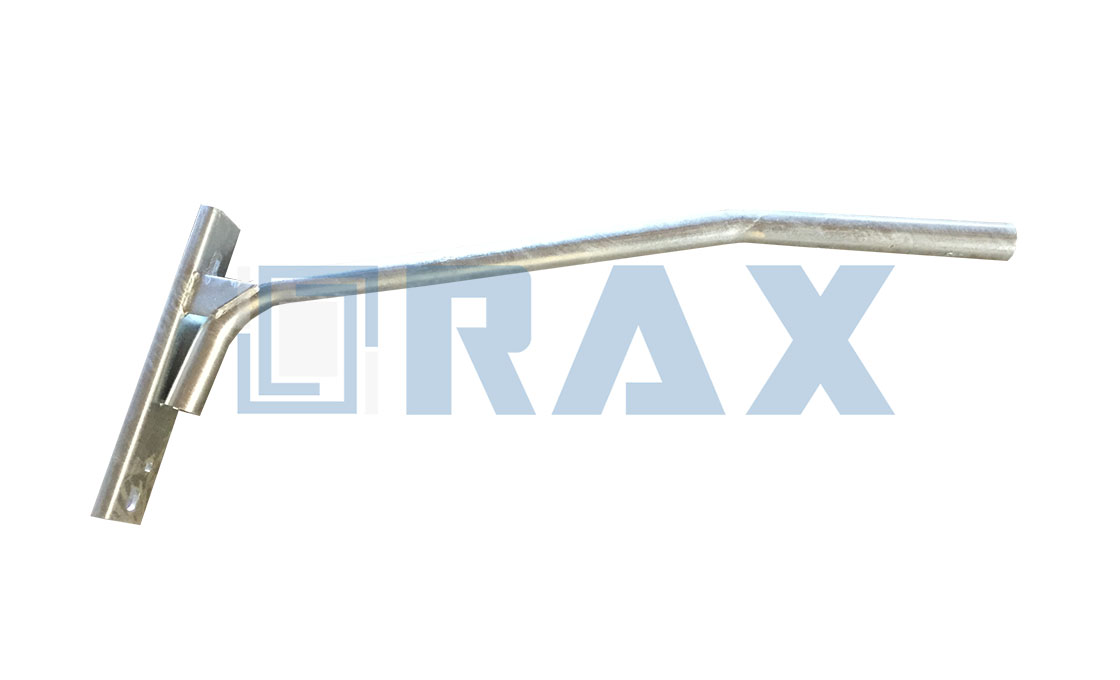

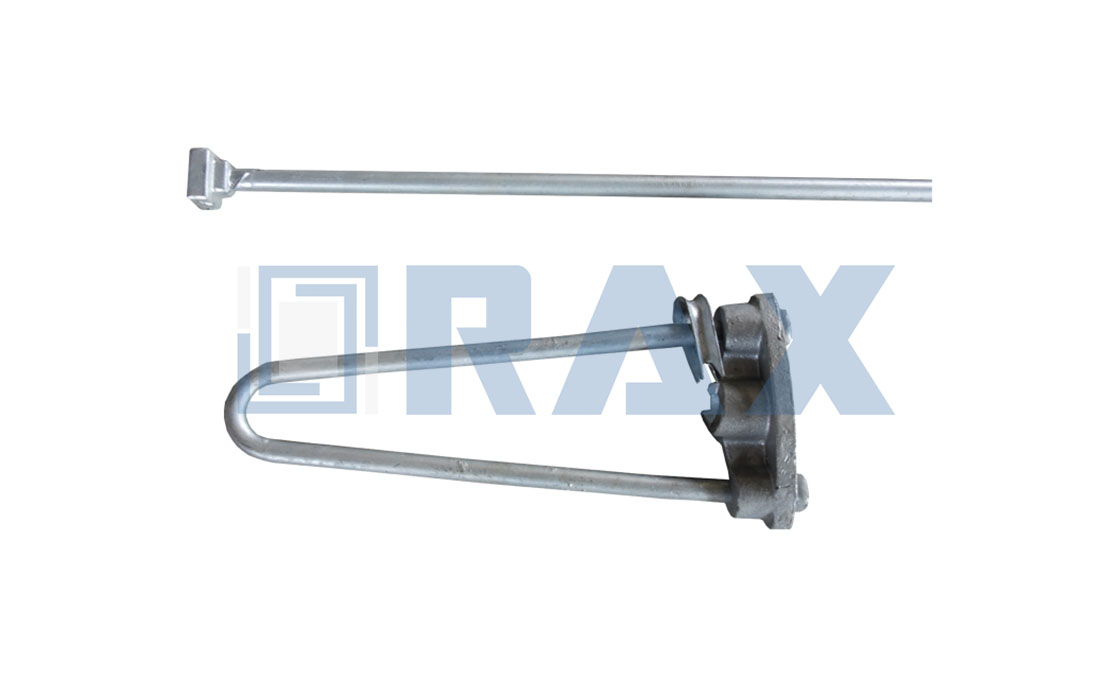

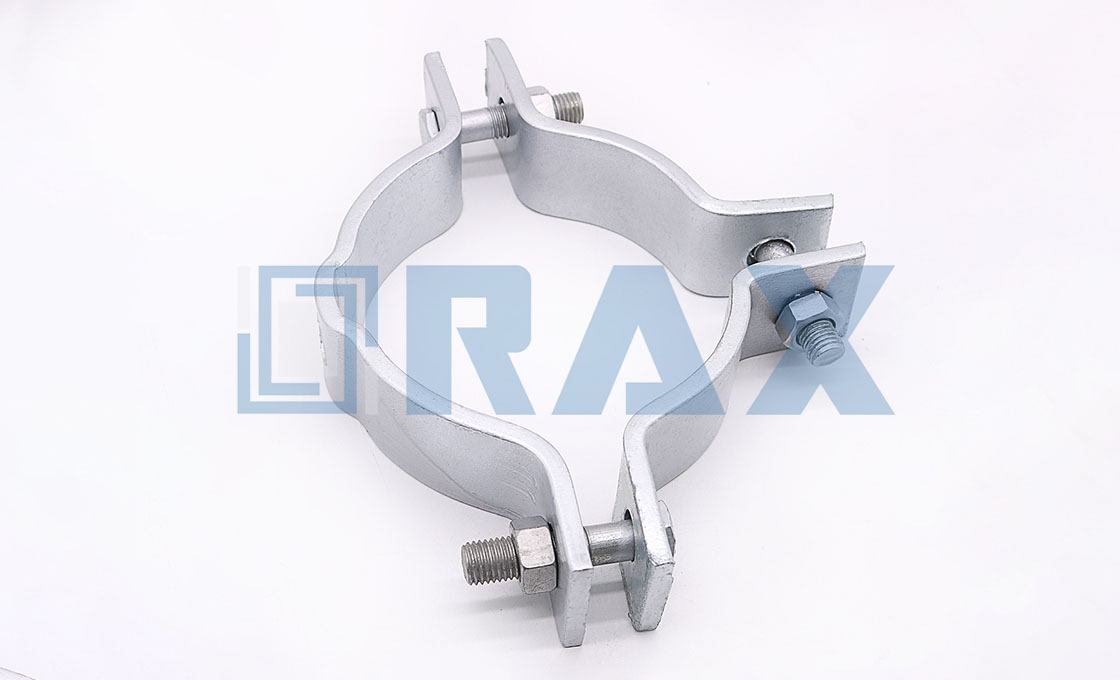

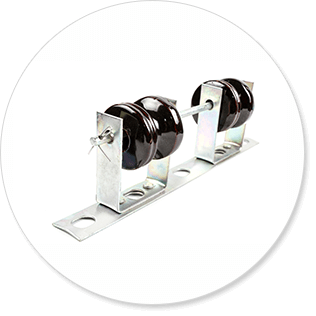

Rax Industry is the leading manufacturer of pole line hardware, formed wire, ADSS/OPGW/OPPC accessory, industrial fastener, electrical insulator, utility anchor, power fitting, and transmission line fitting in China. Rax Industry has been manufacturing for 16 years and has opened the market up in many countries. The creative Rax Industry team uses the automatic machine to keep the sizing accurate and keep your delivery on time. Thousands of semi-automatic moulds have improved production and efficiency. All the products will be reviewed twice before packing. More About Us

Rax Industry Products

Why Customers trust Rax Industry

Factory Price Free Stock Supply:

We help customers collect goods from other suppliers and send them together with our pole line hardware.

Second-time Selection before Sending:

This step will promise the customer to get perfect pole line hardware of 100% quality.

Automatic Machine:

Making the pole line hardware more accurate and uniform.

Professional team:

With more than 15 years of experience in manufacturing, Rax Industry team works efficiently and keeps quality stable.

SGS TEST Passed:

QC 10 persons control the quality of every step, and choose raw material strictly.

Thousands of Sets of Tooling:

Working with more than 11 markets, Rax Industry develops different products for each market.

Custom Design Acceptable:

Never stop developing new types of pole line hardware, helping customers earn more money.

Leading Technology on Forged:

Upgrading the technology level to lower the cost, updating the machines to keep up with the new trends.

Experienced With Market Russia, South America, Southeast Asia

Russia Market Product

Customers ask for a high breaking load in Novosibirsk, and we do load tests before each batch.

Russia’s market pole line hardware is different from America and Africa. There are CPC-7-16,y1k-7-16, yck-7-16. We also supplied different types of ADSS cable accessories.

We have opened the market in Peru, Chile, Dominica, and Ecuador. To reach the perfect quality requirement in South America, the QC department does the inspection very strictly.

View details

View details

Southeast Asia Product

We have achieved many tenders in Malaysia, the Philippines, and Vietnam. We know the test standard, know the manufacturing process.

View details

View details

Welcome to visit Rax Industry factory Request a Quick Quote

How We Control The Quality of Pole Line Hardware

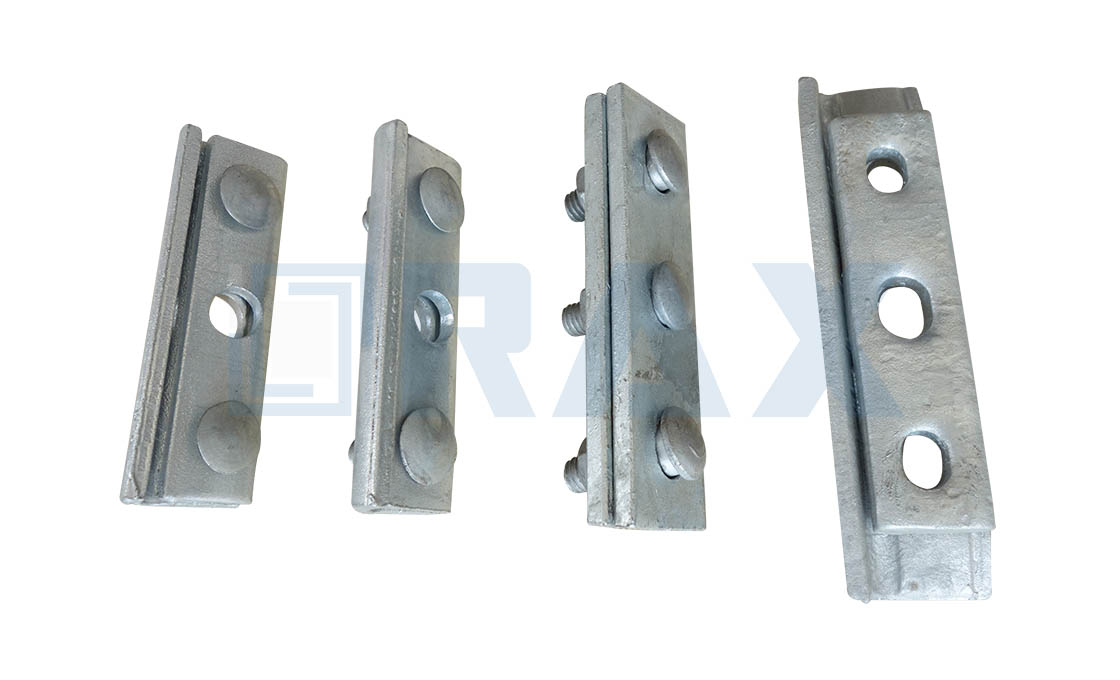

Gauges Test According to IEC 120:

The tolerance for the gauges follows the connection standard. For the ball eye, ball clevis, and socket clevis, a test gauge is a necessary way to control quality. The “GO” gauge should ask all parts to pass through, and the “NO GO” gauge should ask all parts not to pass through, only the two gauges both act well, and the pars can pass the test gauge.

Galvanized Thickness Test According to ISO 1461:

The test device should be calibrated per 500 times. It’s essential to calibrate the equipment before each test. According to ISO 1461, The article will cover a thickness of more than 6mm, Mean coating thickness should be more than 85 microns. The surface should be smooth and bright. If there is a sharp edge, the workers should remove it with tools.

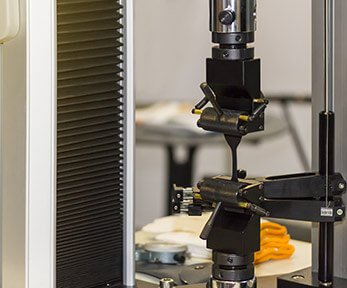

Load Test Before Sending Order:

There are different types of loading test machines, like straight-up type and laying type. The straight-up type is mainly to test short pole line hardware, like ball sockets, glass insulators, and spindles. The laying type is with more functions. It can test both long and short. The preformed suspension clamp and preformed tension clamp are tested by the laying type.

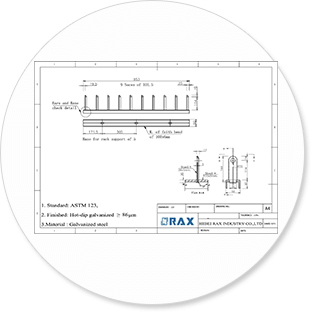

Develop Your Perfect Pole Line Hardware

If you have any new designs, you can send us a drawing or sample, and our engineer will make it come true.

Based on your idea, we will confirm the final drawing and make new tooling. Tooling cost will refund after 5000pcs order.

Become Experts When Importing Pole Line Hardware

What is the Manufacturing Process?

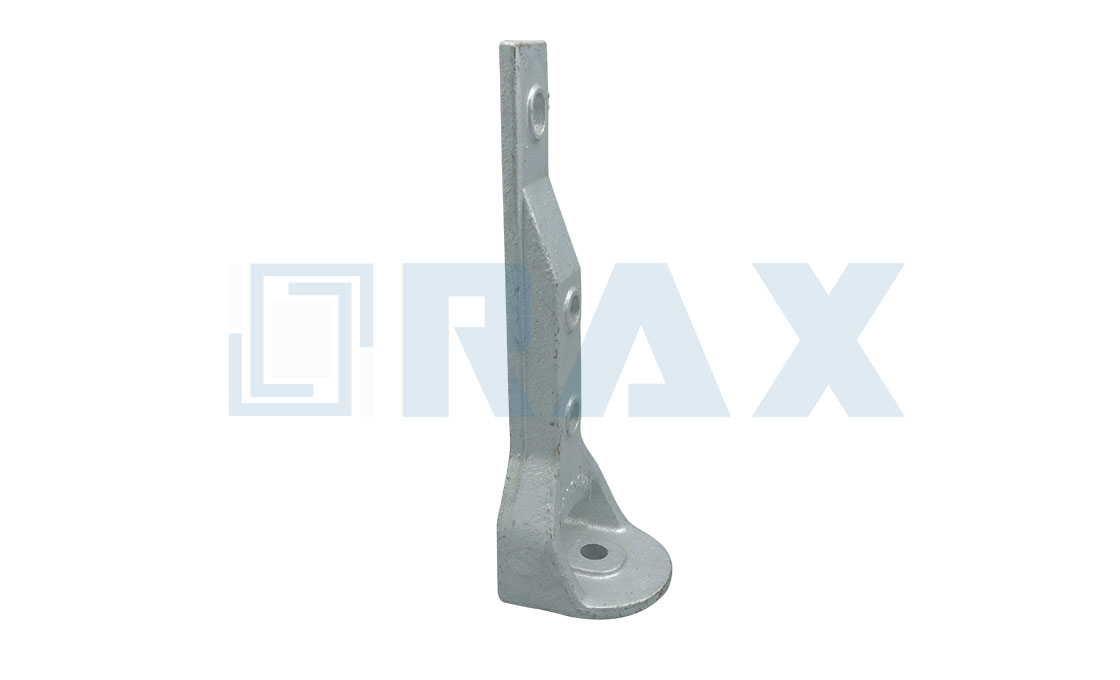

Step by Step Pole Line Hardware Manufacturing Process:

For different pole line hardware, there are various ways to make it. The most sophisticated technology of us is hot forged. The hot-forged part is with more strength than the casting part, and the size is more accurate. While the shortage is the price expensive.

How to Make the Perfect Products?

With the environmental control more and more strictly in China, galvanization is more complicated and more expensive. The technological way of galvanization is also developed. For different sizes of the pole line hardware, the galvanization bow is big or small. For the cross arm, allay arm, steel brace, straight light arm, we choose the big bow.

For pole line hardware, we usually test the size, strength, and hot-dip galvanized thickness accurately. Before testing the strength load, we need to confirm the connection way to test them. A wrong connection affects the strength result. All the test equipment should be calibrated every year according to the standard.

BOSS NOTE

We aim to make the quality to be NO. 1. Rax Industry is your reliable pole line hardware manufacturing in China. More than a supplier, you need a partner!