Non-Gapped Line Arrester

Non-gapped line arrester is a surge protection gadget that helps protect electrical equipment protection from overvoltage as a result of switching surges and lightning strikes. Compared to traditional surge arresters, NGLA do not have any external gapped structures, which makes them to be very reliable, especially in operations and highly effective in electrical mounting applications.

Usually, strikes of electrical surge have high voltages that can damage equipment when they automatically pass and hits it. As a result, equalization occurs, triggering large electromagnetic fields that can damage equipment like electrical cabling. Here, is where NGLA comes into play.

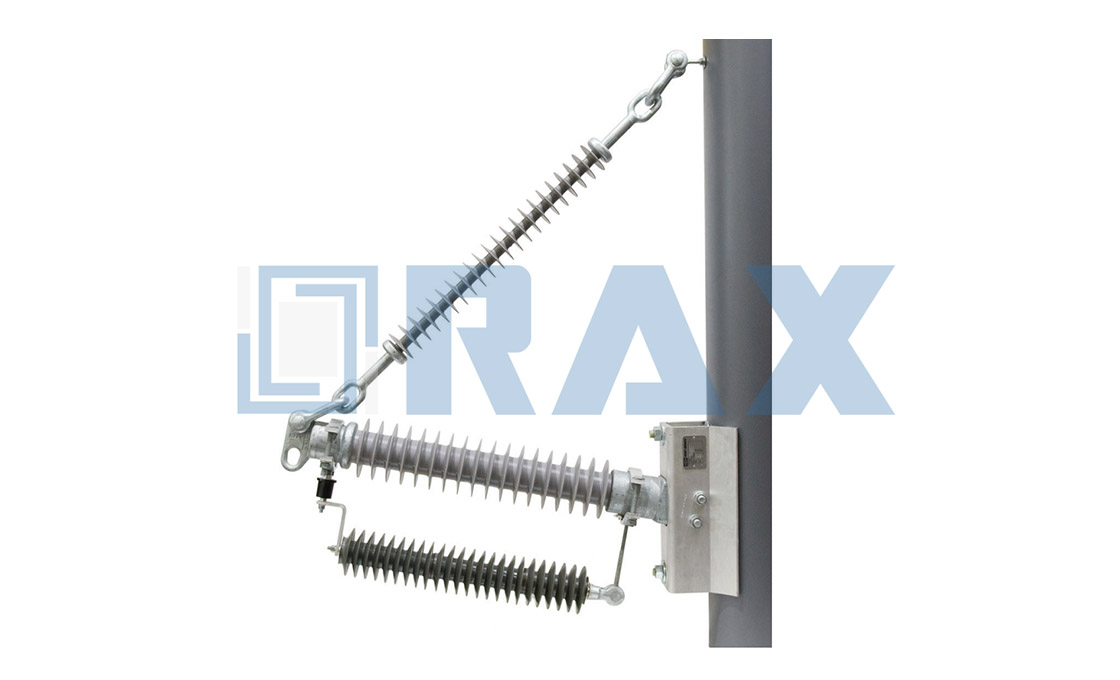

It can be directly installed on the tower or on the insulators based on how the tower is designed and how the line and insulators are arranged. It has a high capability to absorb energy, thus providing very extremely protection level against overvoltage triggered by lightning and network-caused switching impulse current overvoltage.

Key Features

- Facilitates nonstop operation under normal system voltage without causing any interruption

- Vigorous protection against switching and lightning-induced overvoltage.

- High mounting flexibility because they can be installed on the tower itself or on the insulators

- Low maintenance cost due to their compact design

- Have high longevity

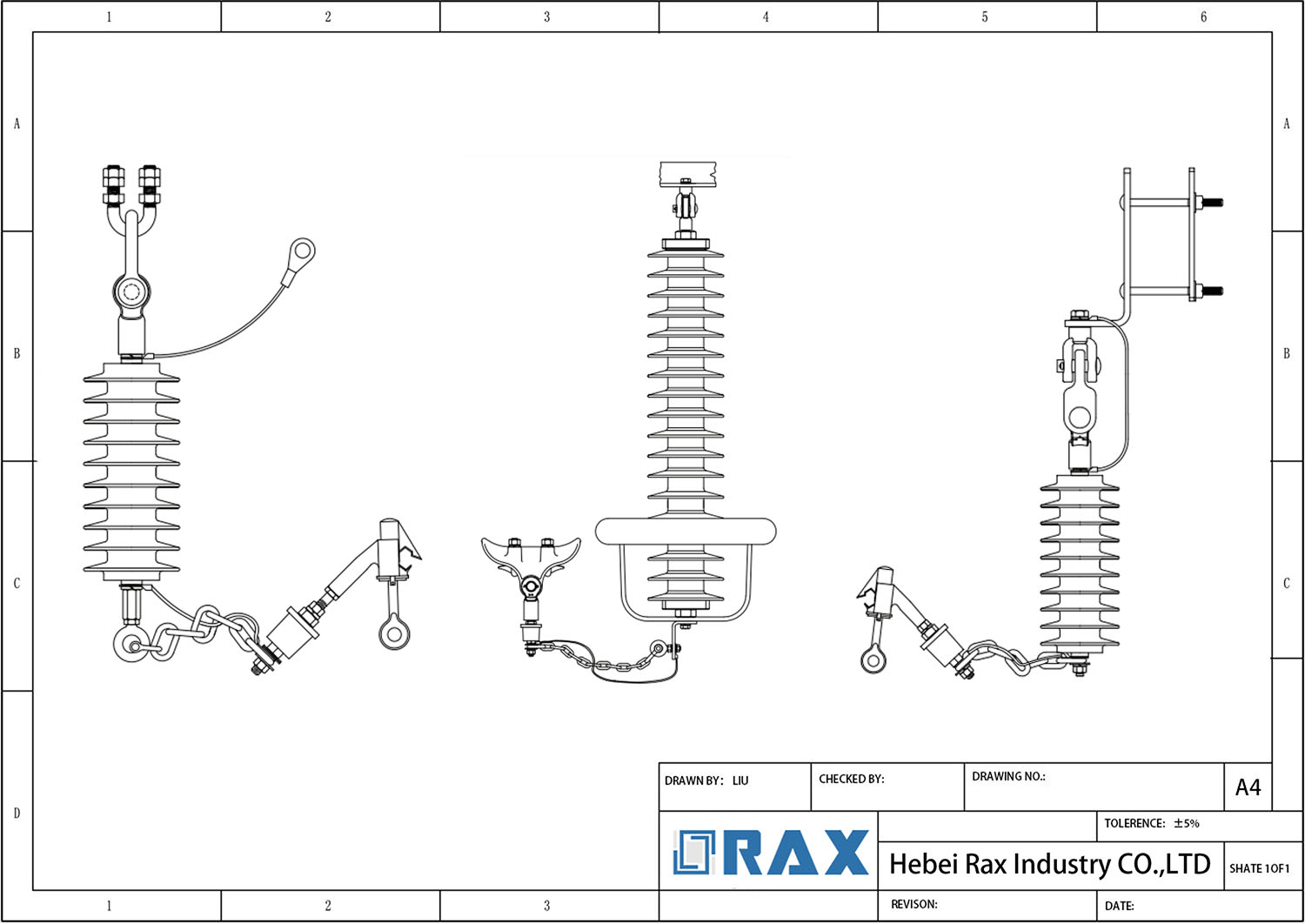

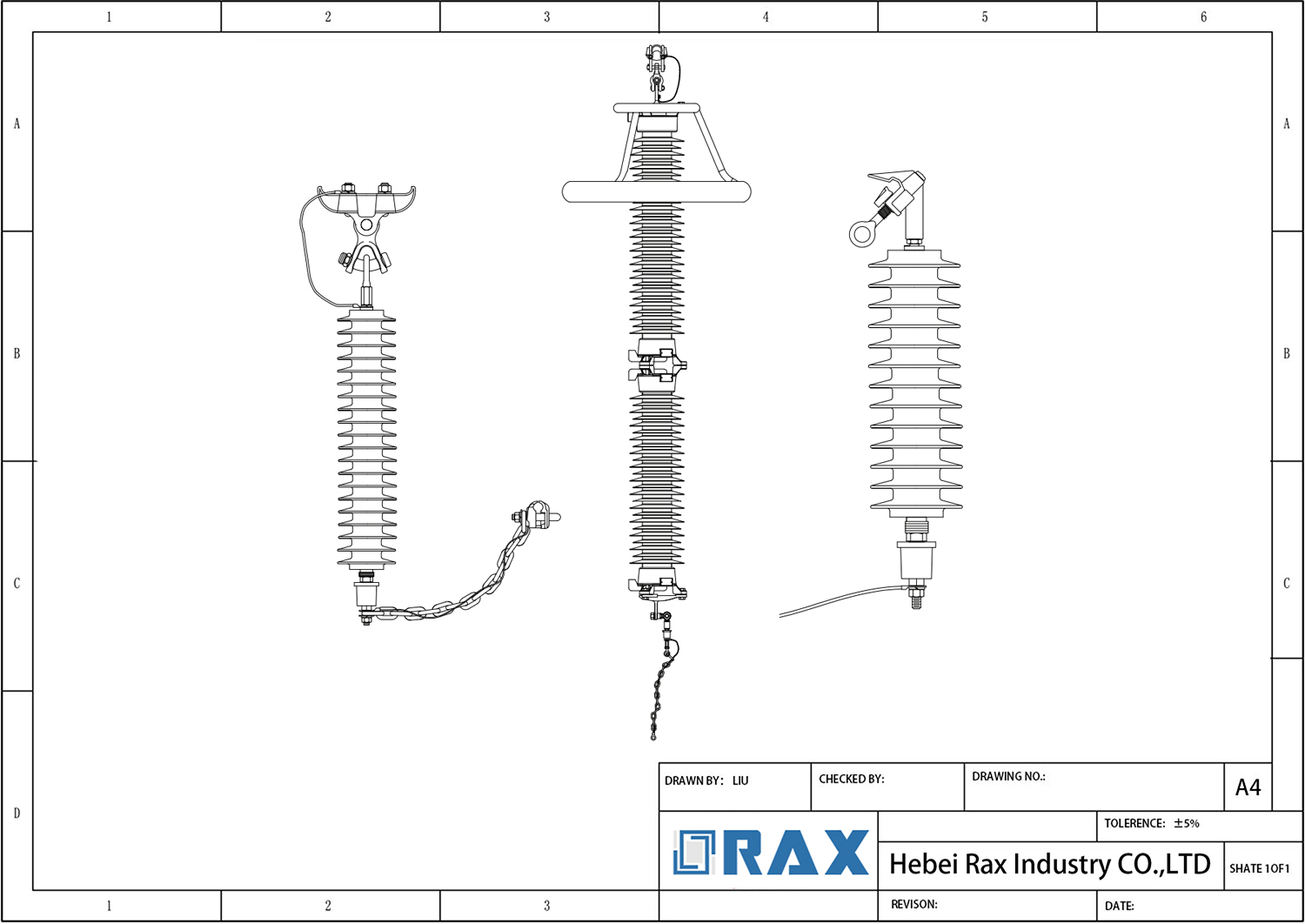

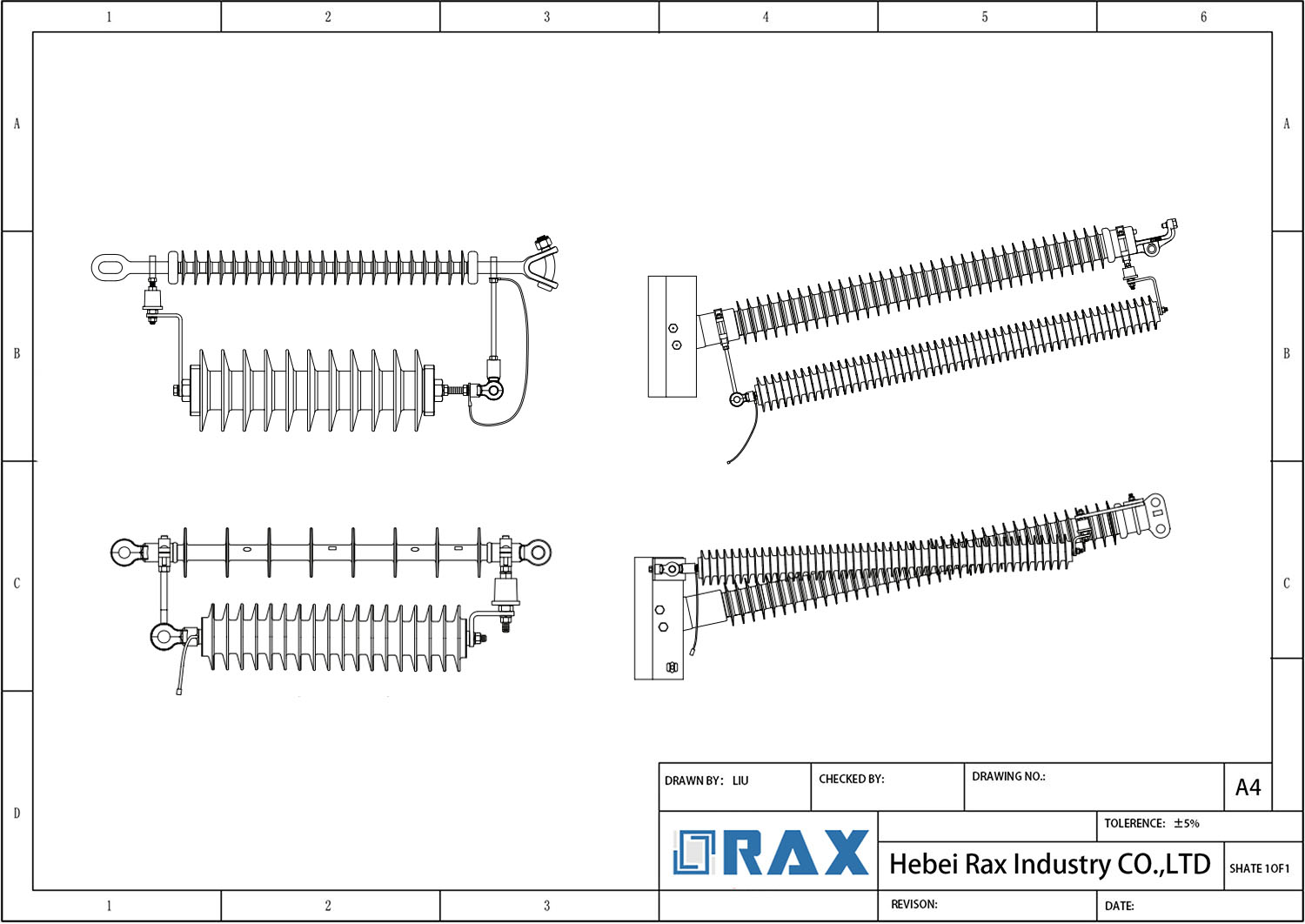

Tower Nount Non-Gapped Line Arrester Drawing

Conduct Mount Non-Gapped Line Arrester Drawing

Insulator Mount Non-Gapped Line Arrester Drawing

| Model type | Rated voltage | Continuous operating | DC U1mA reference voltage | Residual voltage(kV) | Discharge current | 0.75 U1mA leakage current (μA) | Creepage distance | ||||

| (kV) | voltage | (kV) | (mm/kV) | ||||||||

| (kV) | Lightning impulse current 8/20μs | Steep current impulse 1/10μs | Switching impulse current 30/60μs | 2ms | 4/10 μs high current (kA) | Degree III of pollution withstand | Degree IV of pollution withstand | ||||

| rectangular | |||||||||||

| current impulse withstand | |||||||||||

| (A) | |||||||||||

| YH5WX-51/134 | 51 | 40.8 | 73 | 134 | 154 | 114 | 400 | 65 | 50 | 32 | |

| YH5WX-51/122 | 51 | 40.8 | 73 | 122 | 140 | 104 | 400 | 65 | 50 | 32 | |

| YH5WX-96/232 | 96 | 72.5 | 134 | 232 | 267 | 198 | 400 | 65 | 50 | 28.2 | 31.2 |

| YH5WX-96/250 | 96 | 75 | 140 | 250 | 288 | 213 | 400 | 65 | 50 | 28.2 | 31.2 |

| YH10WX-96/232 | 96 | 72.5 | 134 | 232 | 267 | 198 | 600 | 100 | 50 | 28.2 | 31.2 |

| YH10WX-96/250 | 96 | 75 | 140 | 250 | 280 | 213 | 600 | 100 | 50 | 28.2 | 31.2 |

| YH10WX-100/260 | 100 | 78 | 145 | 260 | 291 | 221 | 600 | 100 | 50 | 26.8 | 31.4 |

| YH10WX-102/266 | 102 | 79.6 | 148 | 266 | 297 | 226 | 600 | 100 | 50 | 26.8 | 31.4 |

| YH10WX-108/281 | 108 | 84 | 157 | 281 | 315 | 239 | 600 | 100 | 50 | 26.8 | 31.4 |

| YH10WX-200/520 | 200 | 156 | 290 | 520 | 582 | 442 | 600 | 100 | 50 | 26.8 | 31.4 |

| 800 | |||||||||||

| YH10WX-204/532 | 204 | 159 | 296 | 532 | 594 | 452 | 600 | 100 | 50 | 26.8 | 31.4 |

| 800 | |||||||||||

| YH10WX-216/562 | 216 | 168.5 | 314 | 562 | 630 | 478 | 600 | 100 | 50 | 26.8 | 31.4 |

| 800 | |||||||||||

| YH10WX-312/760 | 312 | 237 | 442 | 760 | 847 | 643 | 600 | 100 | 50 | 26.8 | 31.4 |

| 800 | |||||||||||

| YH10WX-444/1015 | 444 | 355 | 597 | 1015 | 1137 | 900 | 1200 | 100 | 50 | 26.8 | 31.4 |

| 1500 | |||||||||||

Applications of Non-Gapped Line Arresters

- Transmission lines

- Renewable energy systems

- Substations

- Distribution systems

- Railway electrification systems

How Do Non-Gapped Line Arresters Work?

NGLA primarily comprises of metal oxide varistor (MOV), a sensitive semiconductor to voltage. It acts as an insulator at normal voltages, but becomes sensitive and a conductor of electricity at a higher voltage.

When lightning occurs, it activates MOV which immediately conducts the extra current, passing it to the ground as low impedance path. After the system voltage returns to normal fixed value, the current flow to the ground is cut off and the insulation is restored among the conductor and the ground.

Considerations for selecting NGLA

- The maximum voltage of the system

- The type of structure

- The level of insulation for the protection equipment

- Durations and levels of power frequency overvoltage

- Installation method: deenergized or hot line

- Availability of an OHSW

- Environmental conditions

- Availability of line-to-ground fault current

Selection process of NGLA

It can be a challenge to select a suitable NGLA for certain application, even for experts. Therefore, the following steps are recommended, which requires a determination of system parameters first and a selection of the corresponding arrester parameters.

Step 1: Select the appropriate MCOV

The process of selection starts with choosing the correct MCOV that best meets the general application needs.

Step 2: Choose the type of arrester

If you are looking to handle high mechanical loading, or want to engage in excessive lighting duty, then you need to consider certain designs that perfectly matches your application needs

Step 3: Choose the mounting arrangement

Some of the common configurations include suspending the arrester from the tower and mounting the arrester across an insulator.

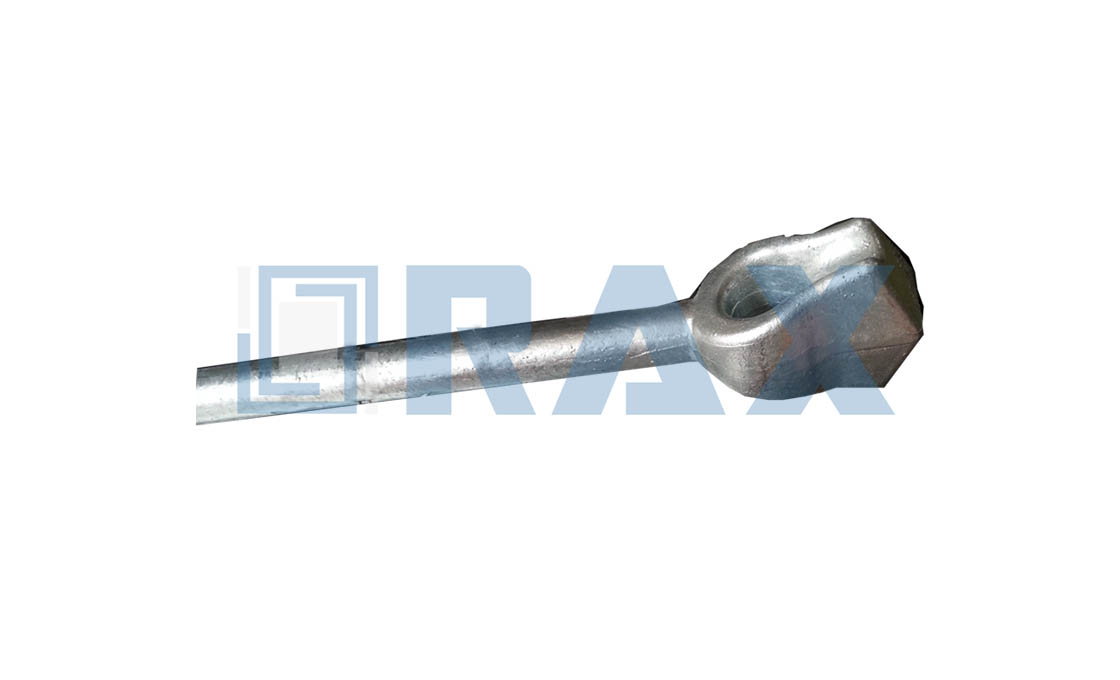

Step 4: Select the correct hardware

Ensure the hardware you choose for installation can meet your application needs.