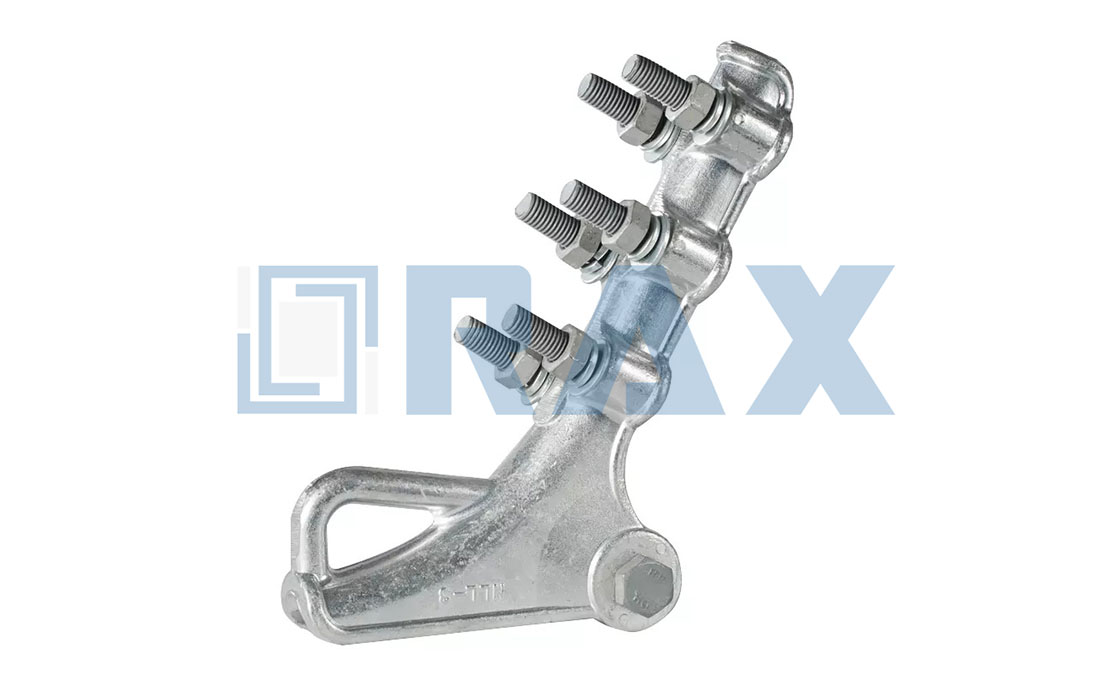

Tension Clamp

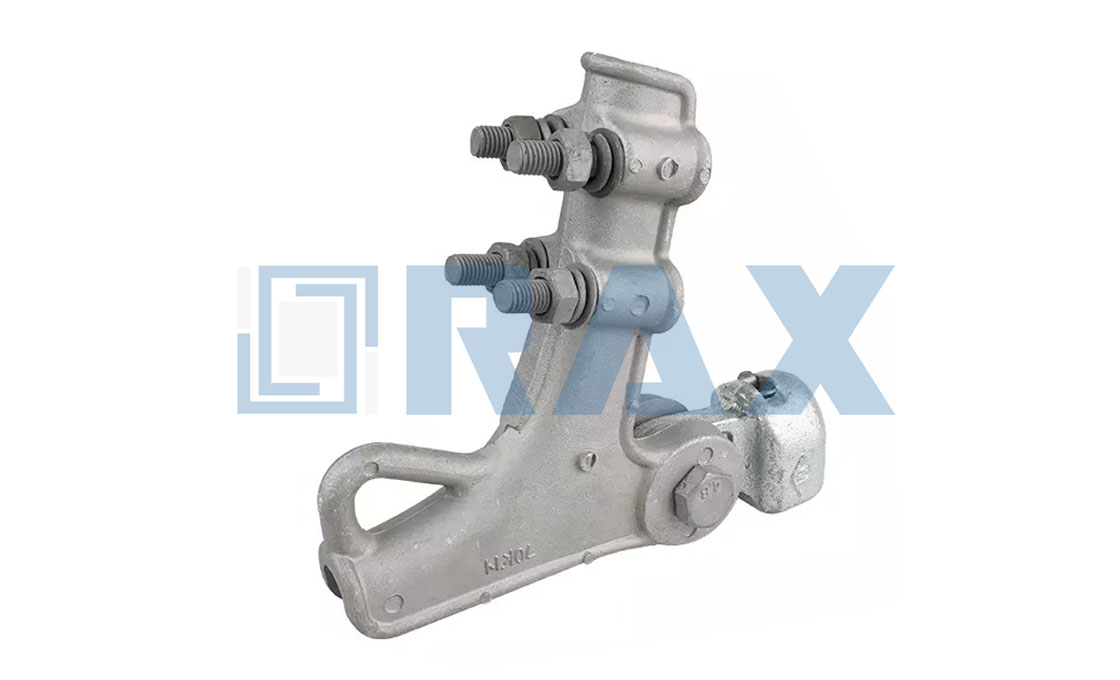

The Bolted Type Dead End Tension Clamp is one type of single tension hardware fitting, it is mainly used on the overhead transmission lines or distribution lines. The tension clamp is also called dead end strain clamp or quadrant strain clamp, it is one kind of transmission line clamp.

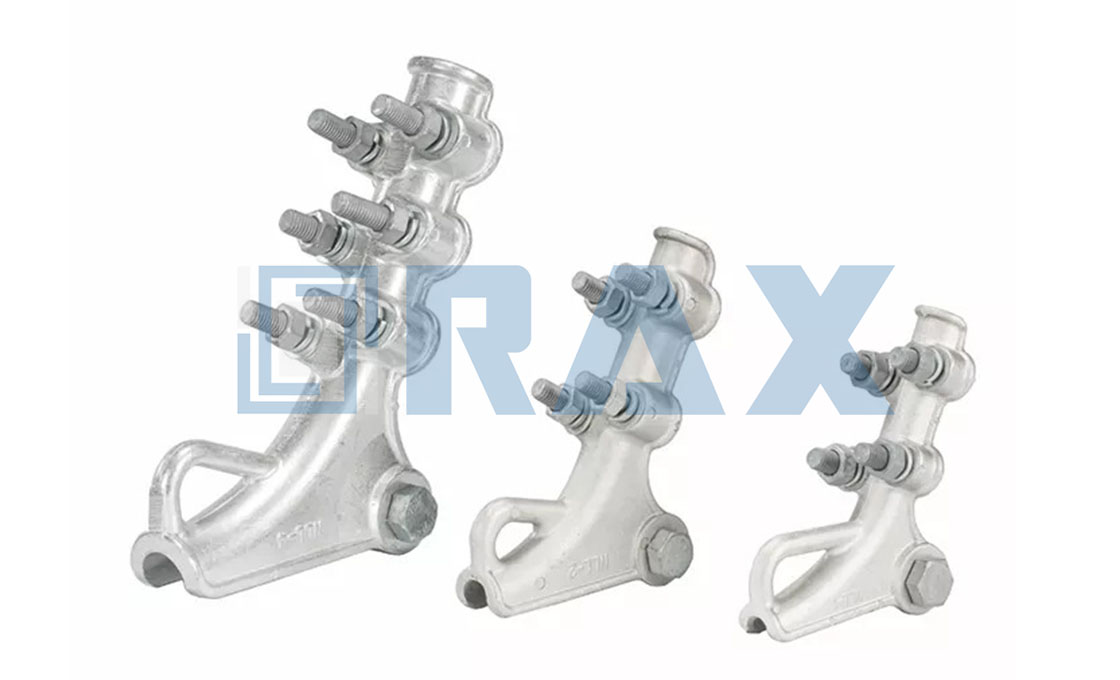

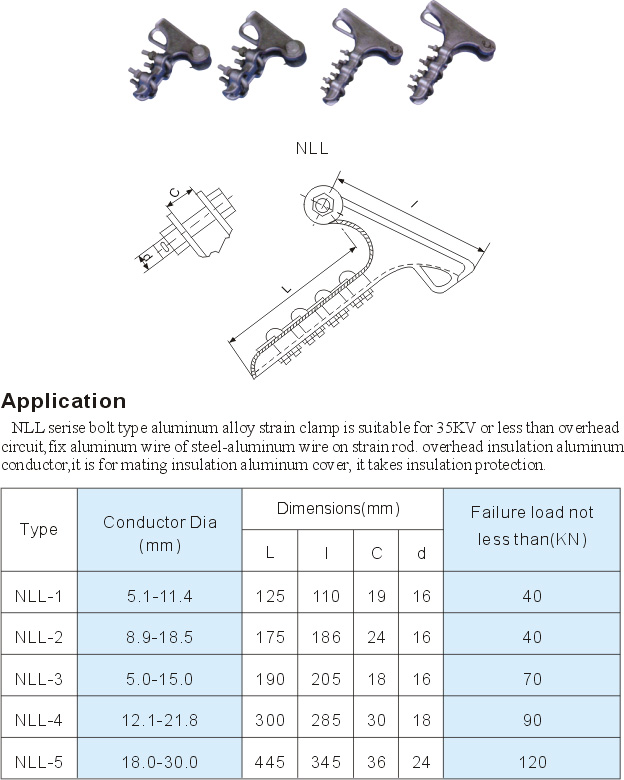

Because the shape of the tension clamp is like a guy, some customers call it guy type or bolt type. According to the conductor diameter, there are different series of bolted type tension clamp such as NLL-1, NLL-2, NLL-3, NLL-4.

The NLL series of bolt type dead end clamp the main body is made from material high strength aluminum alloy which meets the requirements of standard specification in the latest issue of BS.

The bolt type of tension clamp is suitable for aerial lines up to 35kv. Rax Industry bolt type tension clamp is intended for use with ACSR or all-aluminum conductors.

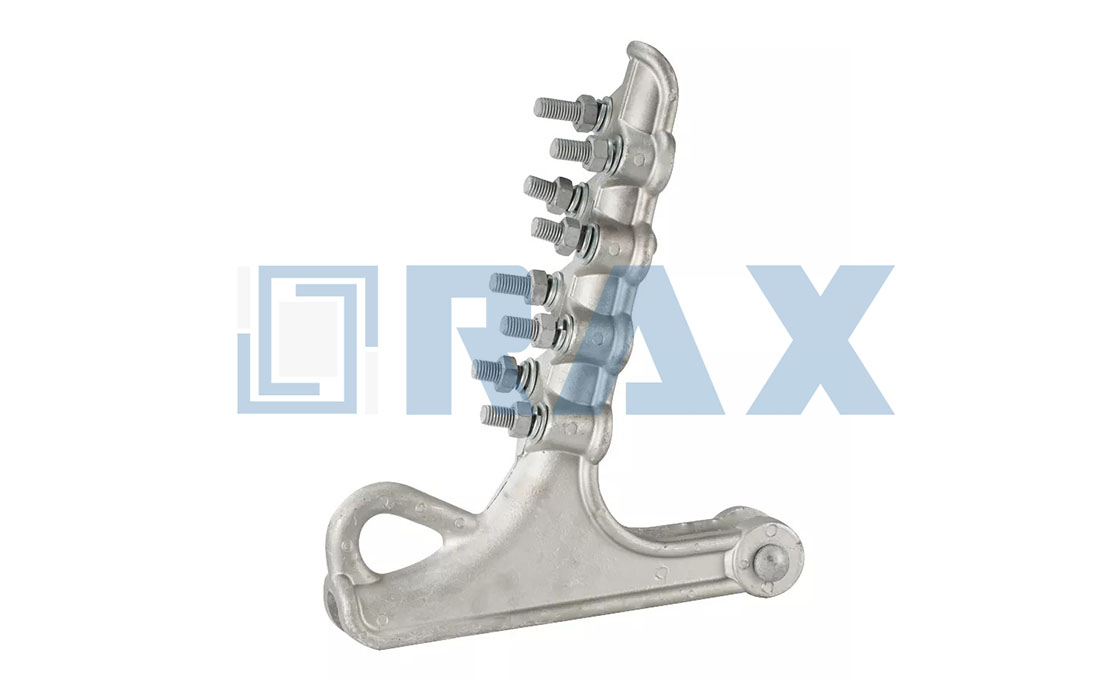

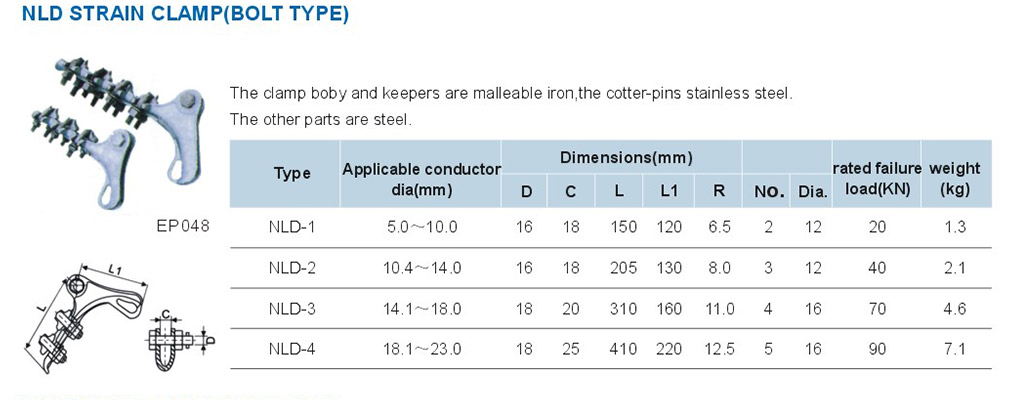

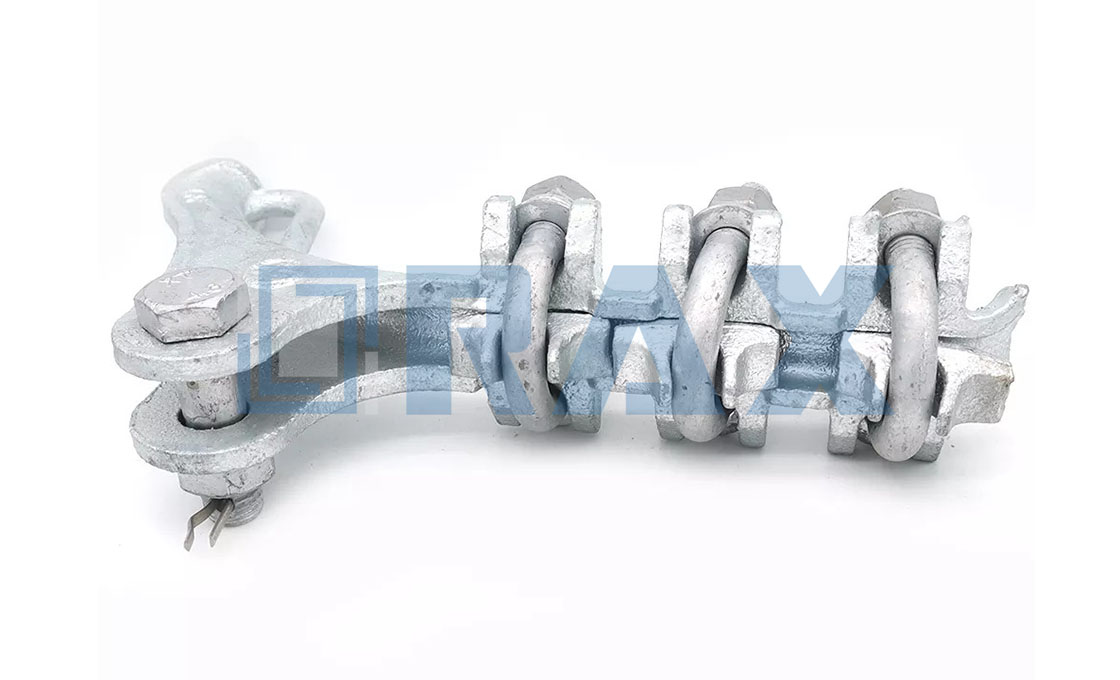

Some clients ask NLL series of bolt type together with the armor tape or special liners to protect the conductor from damage. According to the material, there is another series of NLD-1, NLD-2, NLD-3, NLD-4. NLD series is produced from high strength malleable iron.

NLD series tension clamp is used with aluminum-clad steel conductor. When it is used on the aluminum conductor, it usually assembled with liners.

The above is only introduced the main body of the tension clamp. There are U bolt, nut, and washers required for fasten the conductors into the gun bodies.,

NLL Series of Bolt Type Tension Clamp

NLD Series of Bolt Type Tension Clamp

Design of Clamp

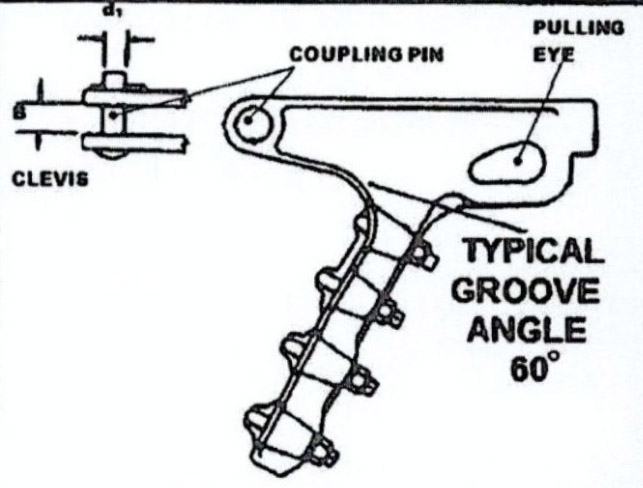

- bolted, quadrant type, with a clevis end fitting, used for termination aluminum or aluminum alloy conductors. Appearance is similar to Figure 1 below.

- Nominal groove angle of 60 as detailed in Figure 1.

- High strength aluminum alloy clamp body.

- Steel U-bolts, each fitted with two hex nuts, two flat round washers, and two lock washers.

- All steel components, except those made of stainless steel, to be hot-dip galvanized in accordance with BS EN ISO 1461:2009 or ASTM A153/153M.

Figure 1: Typical Bolted Dead and Clamp

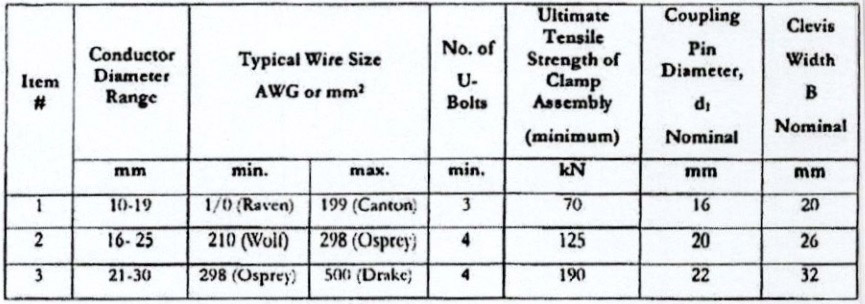

- To accommodate and secure a range of bare overhead line conductors with diameters detailed in Columns 2 and typical wire size in Columns 3 and 4 of Table 1.

- Number of U-bolts provided to secure the conductor in the groove the clamp as stated in Table 1, Columns 5.

- Dimensions of clevis and coupling pin in accordance with Table 1.

- Ultimate tensile strength of clamp assembly in accordance with Column 6 of Table 1.

Table 1: Parameters of the Overhead Line Dead-end Clamp

- Ultimate tensile strength of pulling the eye to be greater than or equal to 60﹪ of the ultimate tensile strength of the whole clamp assembly.

- A split pin made of cold drawn bronze, brass or stainless steel is to be provided to secure the coupling pin in place.

- The minimum failing load of the coupling pin corresponds to the ultimate tensile strength of the whole clamp assembly.

- Clamp assembly to be free from cracks and other visible defects, with no sharp edges and burrs. Leading edge of the contact surface near the pulling eye to be flared to minimize damage to the conductor.

Customized Markings

The dead end clamp can be legibly and durably marked, in any words with the following:

- Customs’ identification mark or symbol;

- Tensile strength of the clamp;

- The conductor diameter range.

This specification references the following standards:

BS EN ISO 1461:2009- Hot dip galvanized coatings on fabricated iron and steel articles. Specifications and test methods

ASTM A153/153M- Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware

IEC 60471:1977- Dimensions of clevis and tongue couplings of string insulator units

This specification was informed by the following standard:

BS 3288-2:2009-Insulator and conductor fittings for overhead power lines.

If you choose Rax Industry tension clamp, there is no electrolytic action occurring between the clamps and conductors or between the various parts of the tension clamp When installing the tension clamp.

There is no slippage that occurs up through 90 percent of the rated ultimate strength of the clamp when the clamp holding the conductor.

On each tension clamp surface, it shows the available range of the conductor and the manufacturing marking. As an OEM service provider, we can mark the customers’ mark as required.

The tension clamp has the features of Minimizing hysteresis and eddy currents in the clamp and accepting cool operating temperatures

The tension clamp is usually installed at the tension pole to help the conductor turn in a different direction.

Jinyong tension clamp design and services team had been offered a high-quality tension clamp and strain clamp for over 200 customers all around the world. With Rax Industry full range of experiences and up-to-date technology, Rax Industry has been focused on tension clamp manufacturing, design, and development.

Tension Clamp – The Ultimate Guide

Tension Clamp

Tension Clamp

Dealing with cables for electrical and telecommunication systems has never been easy.

There are many things that you need to take care of especially when you are planning to hang the cables on poles and towers.

Apart from ensuring that the cable transmits data or electricity smoothly, you need to be concerned about its physical structure.

The good news is there are several tools that have been designed to ensure that the conductors remain stable and well-supported when transmitting data and electricity.

One of these tools is the tension clamp.

What is a tension clamp and how does it work?

Before you buy a tension clamp, spare some moments to read through this comprehensive guide.

What is a Tension Clamp?

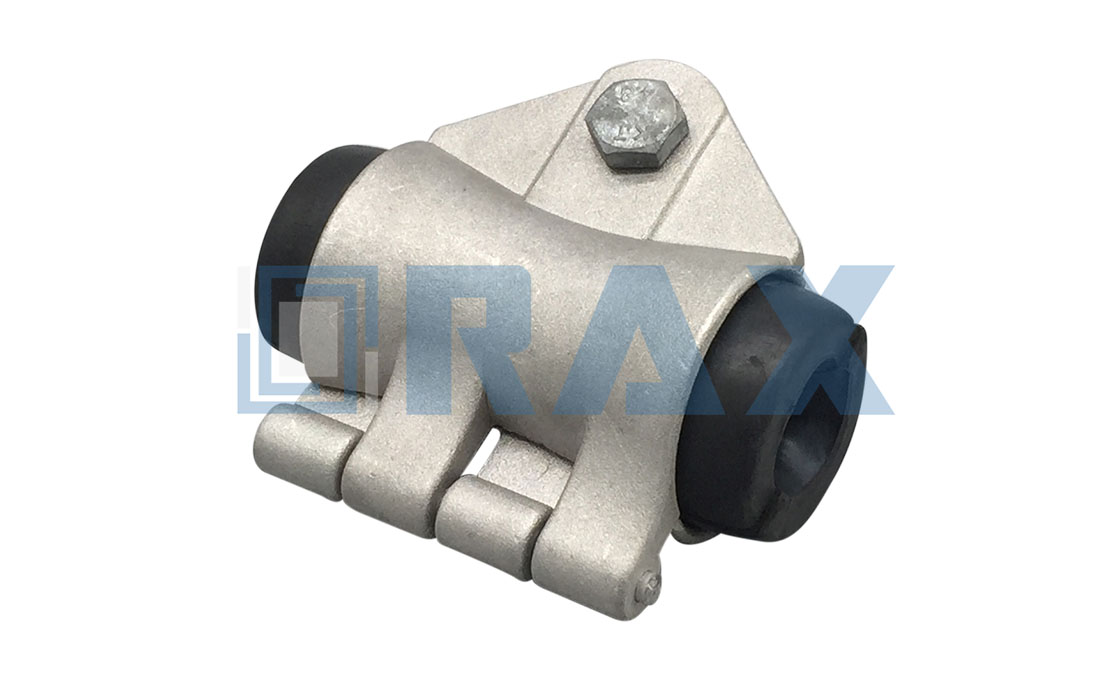

This is a simple device that comprises of several parts which are used for terminating conductors at different points. The device is also used to provide adequate mechanical and electrical connections to the insulator which is around the conductor.

The clamps can support conductors on the straight sections and as well as those on the twisted sections.

When in the twisted sections, tension clamps up to an angle of 90 degrees.

Uses of Tension Clamp

Uses of Tension Clamp

Uses of Tension Clamp

So what are the real-life applications of tension clamps?

We have just mentioned that tension clamps are mainly used in the electrical and telecommunication industries.

But, what exactly do they do?

Here are some of the uses of tension clamps:

-Provide a strong mechanical connection

Tension clamps are designed to provide strong and safe mechanical and electrical connections regardless of the conditions.

Whether the cables are having longitudinal tension or even maximum working loads, tension clamps are still able to provide an adequate connection that is coupled up with the longitudinal grip.

-Protect the conductor

The design of the tension clamps enables them to protect the conductor

They provide this protection at the installation loads.

-Limit the movement of the conductor

Usually, conductors and transmission lines are exposed to the vagaries of nature such as wind and storm.

Sometimes, the wind can be too strong such that it can cause movements and vibrations of the conductors.

In doing so, the vibrations can emanate from the conductor and data lines

By controlling random movements, tension clamps help to limit the vibrations that emanate from the conductor.

Although there could be other functions of the tension clamps, the three that we have mentioned are vital for any overhead lines.

Components of a Tension Clamp

Tension Clamp

Tension Clamp

Although a tension part may appear like a single unit, it is not.

Instead, it is made up of different components.

Here are the main parts of a tension clamp:

1. The wedge and body: This is the main part of the tension clamp. It supports the conductor of the overhead lines

2.Washers: This part is right next to the body. Its function is to protect the surface of the conductor when the bolt is fastened.

3.Straps: The straps are responsible for transferring the load from the axis of oscillation to the insulator ring

4.Threaded inserts: These parts are also known as the threaded bushing.

They play the fastening role whereby they add a threaded hole in an object.

5.Bolts and Nuts: Like in other mechanical objects, bolts and nuts complete connections between different objects in a tension clamp.

Materials used on Tension Clamps

What type of material is used to make tension clamps?

The main materials used are aluminum and cast iron.

These two materials are preferred because they are compatible with conductors.

In addition to that, they can survive well under different conditions without corroding or rusting.

The selection of these two materials is also based on their minimum hardness.

They are extremely hard and can’t be easily affected by temperature changes.

Design Characteristics of Tension Clamps

The design of a tension clamp dictates its physical interaction with the conductor and even overhead lines.

The design of the clamp should allow it to move freely along the conductor.

Even while moving, the design should be in such a way that it does not cause any kind of fatigue on the conductor.

This is to allow the conductor to operate smoothly.

The hole at which the straps attach themselves to the body of the clamp should be of reasonable size.

It should also not cause any kind of damage.

The aspect of the design extends to the bolts and nuts that are used.

They should be able to get attached to the clamp well.

Types of Tension Clamps

Do you want to buy a tension clamp?

Will, you may have to hold back until you decide the specific type that you want.

This is because there are different types of tension clamps.

The difference is mainly based on their designs.

Here are the main types of tension clamps that you are likely to buy

1.Wedge tension clamps

You are likely to find wedge tension clamps at the substations and on the overhead lines.

Why are they known as wedge clamps? Do they have a wedge?

The name is because the clamping on the conductor is due to the wedge action.

It converts the tension load into the compressive clamping loads.

An increase in the tension loads automatically increases the longitudinal wedge movement.

This ends up increasing the strength and clamping forces.

The friction on the wedges can be reduced by special lubrication. Low friction increases the mechanical grip of the tension clamp.

A wedge tension clamp can have a jumper connection or can still work without this connection.

The two forged bodies are connected to each other by screws.

2.Cone tension clamps

Cone tension clamp has a similar working mechanism with the wedge clamp.

The only difference is that this time the clamping force is provided by the cones.

Also, the cones can work with or without the jumper connections.

3.Tension clamps for high temperature

These are just ordinary clamps only that they are well-designed to suit high-temperature conductors.

They are mechanically and structurally strong so as to withstand high temperatures without affecting the conduction.

Conclusion

Now that you have some valuable information about tension clamps, what next?

Of course, the next step is to contact a reliable tension clamps manufacturer and complete the purchase.

At Rax Industry, we are proud of manufacturing and supplying high-quality tension clamps

In case you need one, don’t hesitate to contact us.

FAQ

What is a tension clamp?

The tension clamp is one type of single tension hardware fittings, it is mainly used on overhead transmission and distribution lines. The tension clamp is also called dead end clamp, it is one kind of transmission line clamps.

What are the components of a tension clamp?

- The wedge and body

- Washers

- Straps

- Threaded inserts

- Bolts and Nuts

What is the function of tension clamp?

Here are some uses of tension clamps:

- Provide a strong mechanical connection

- Protect the conductor

- Limit the movement of the conductor

What are the types of tension clamps?

Here are the main types of tension clamps:

- Wedge tension clamps

- Cone tension clamps

- Tension clamps for high temperature