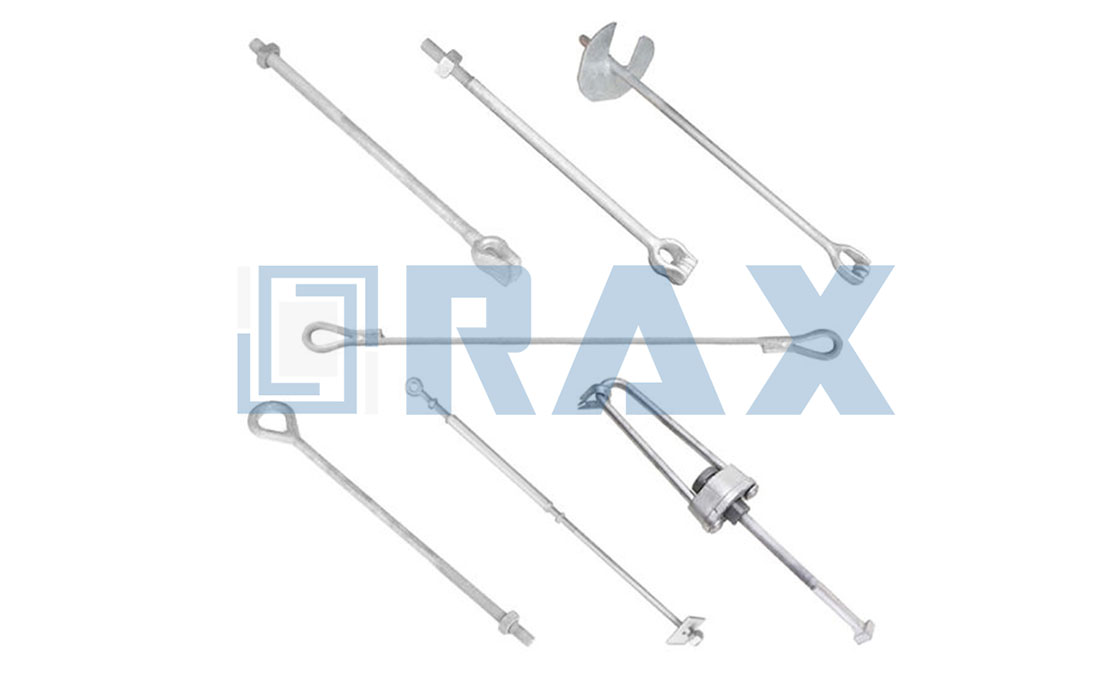

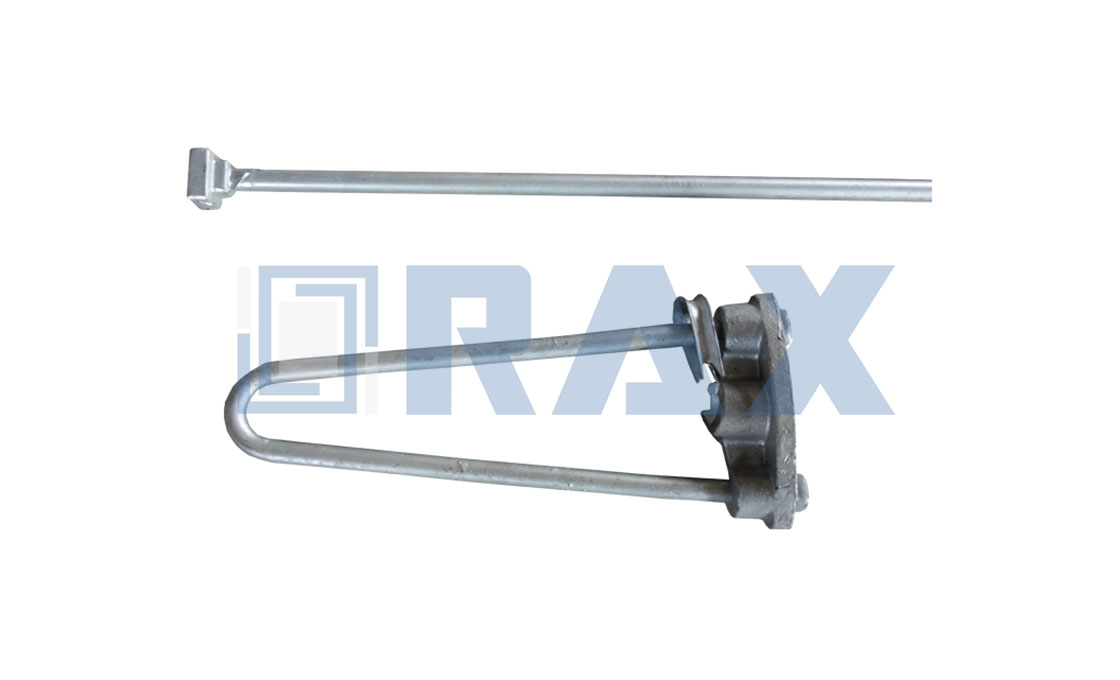

Stay Rod

The stay rod is also named bow stay rod or stay set, it is a component used to connect the stay wire to the ground anchor. There are two types: bow stay rod and tubular stay rod. The bow type stay rod includes stay bow, stay rod, stay plate, and stay thimble. The tubular stay set is adjustable by means of an eye topped of the turnbuckle.

The difference between the bow type and the tubular type is the structure. Without the stay bow, the Tubular type stay rod includes turnbuckle and eye rod. The tubular stay rod is mainly used in Africa and Saudi Arabia. The bow type stay rod is widely used in Southeast Asia,

As a professional manufacturer, supplier, and exporter, Rax Industry has years of experience in making the stay set, our stay rod is widely known for its high durability, sturdy structure, and uniform size and galvanize.

| Product Specification Stay rod | ||||||

| Code | D | d | I | L | Surface | Approx weight |

| JY-SR-01 | 20 | 16 | 355 | 2750 | Hot dip galvanized | 10.5 |

| JY-SR-02 | 24 | 20 | 355 | 3200 | Hot dip galvanized | 13.5 |

| JY-SR-03 | 20 | 16 | 355 | 2500 | Hot dip galvanized | 11.5 |

| JY-SR-04 | 16 | 16 | 355 | 2000 | Hot dip galvanized | 10.0 |

| JY-SR-05 | 24 | 20 | 355 | 2500 | Hot dip galvanized | 11 |

| JY-SR-06 | 24 | 24 | 355 | 2440 | Hot dip galvanized | 16.5 |

Stay Rod: The Complete Guide

I know you’re looking for a reliable and high quality stay rod for your pole line installations.

If that’s the case, then you’re in the right place.

Because I am going to take you through every detail about stay rod – from the basic definition, applications, applications to specifications of stay rod.

Keep reading to be an expert in pole line hardware.

What are Stay Rods?

The stay rod is also named stay set, it is used to connect the stay wire to the ground anchor. A stay rod is a major component of the pole-line technology,

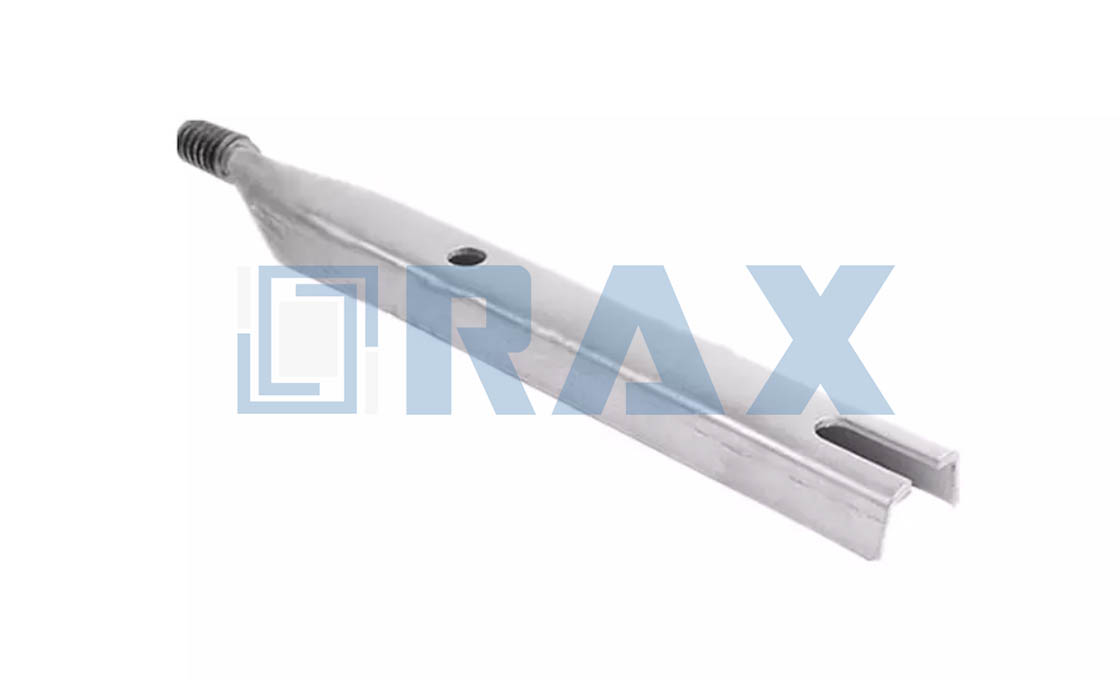

Stay rod

Stay sets are manufactured to perform a wide range of activities in different environments and weather conditions.

It is a set with a combination comprising of:

- Stay plates

- Stay rods

- Eye bolts

- Turn buckles

- Nuts and thimbles

The stay set is usually made of steel as the main material taken through a number of processes to give it a fine finish.

Stay rod

Stay rod

Main Uses of Stay Rods

Stay rods offer mechanical support to joined parts.

They support them from collapsing under extreme pressure.

Let’s look at a few applications:

i. In the electric field, it is used to stay tower structures and power poles.

ii. In pole-line technology, different forms of stay rods are used in pole lines, distribution lines, and telecom lines.

Now, let me walk you through the different types of stay rods.

Types of Stay Rods

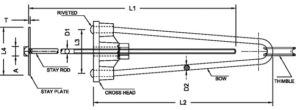

Stay rods are divided into two main types including the bow type stay rods and the tubular type stay rods.

Bow type stays rods include:

- Stay bows

- Stay thimbles

- Stay plates

- Stay rods.

Also, the tubular types have two main types including:

- Eye stay rod

- turn buckle stay rods

The major difference between the tubular type and the bow type is in the structure.

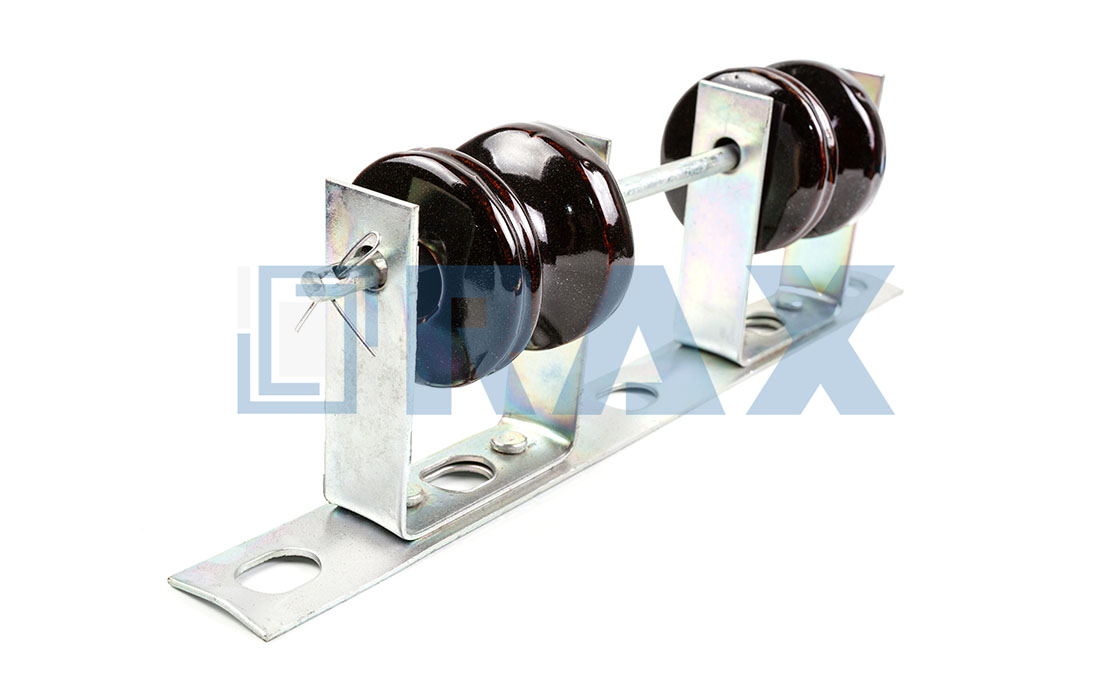

Components of stay rods

Components of stay rods

Tubular types of stay rods are used in a wide range in Saudi Arabia and Africa.

Bow types are commonly seen and used on a wide scale in Southeast Asia.

Bow Types

Some of the main common types of stay rods in this category include:

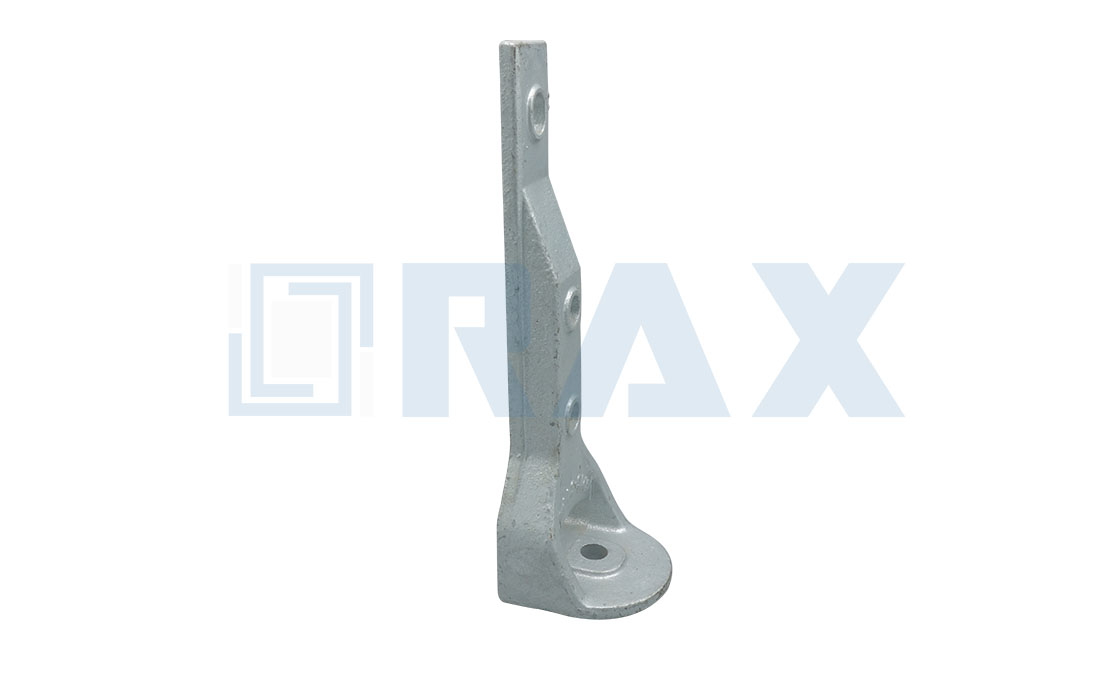

i. Stay Bow

It is a type of stay rod made of steel and the outer surface is treated by hot dip galvanization.

Apart from that, it is strong and durable usually given a life span of 20 years.

Available in different forms in accordance with the specifications of the client.

Main uses include fixing ground wires and conductors through link fitting or insulators.

Apart from that, they are used to tower substation structures.

This is done in accordance with the desired mounting way and clamp construction.

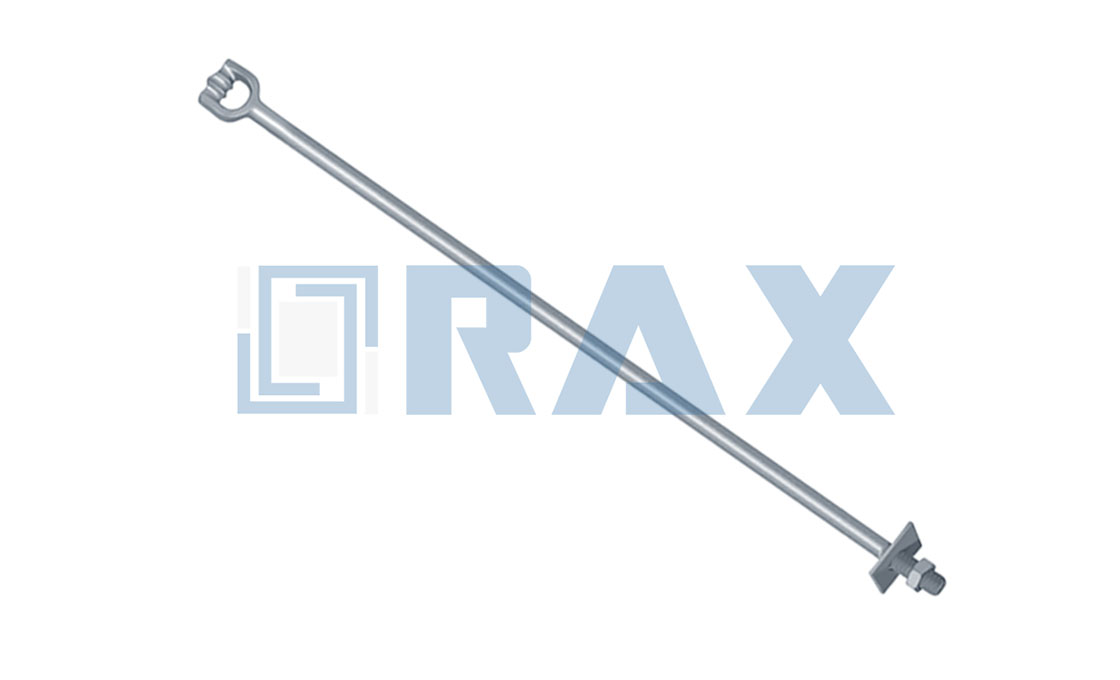

ii. Stay Rod

It is used in quite a number of applications including power transmission, power accessories, and power distribution in power stations.

The main material used in their manufacture includes steel, malleable cast iron, and carbon steel among others.

A stay rod has to go through the following processes before being Zinc-plated or Hot dip galvanized finish.

The processes include: “precision – casting – rolling – forging – turning – milling – drilling and galvanizing”.

iii. Stay Thimble

It is a type of stay rope that is used in quite a number of applications and comes in different forms.

Among them is the wire rope thimble made of carbon steel, and alloy steel to improve its strength and durability.

It is used for fixing wire ropes, marine hardware fitting, and chain fittings among other applications.

Surface treatment applications include electro galvanization, hot dip galvanization while others are painted in different colors mostly silver white.

They are also made in different sizes depending on the specifications of the customer and the intended use.

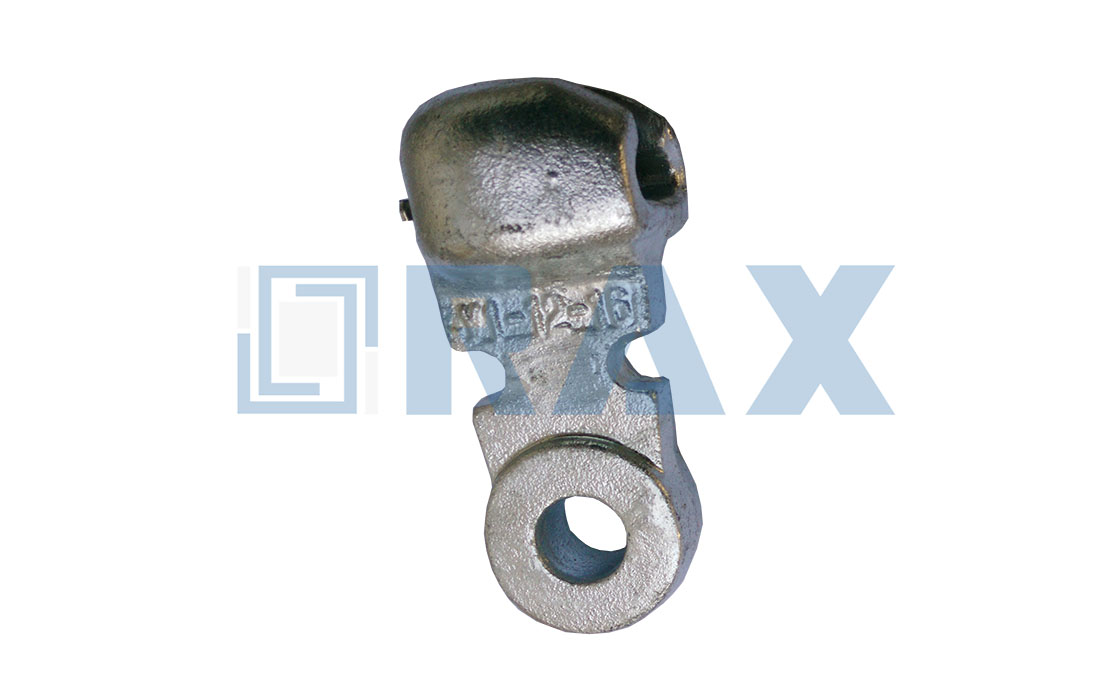

iv. Stay Plate

It is also known as the earth plate, and is a major component of pole-line technology with a wide range of uses.

It is fabricated using mild steel among other materials and hot dip galvanized to offer a fine finish.

It is made in different sizes according to its intended use and customer specifications.

Tubular Types

Under this category, we have the following types of stay rod accessories:

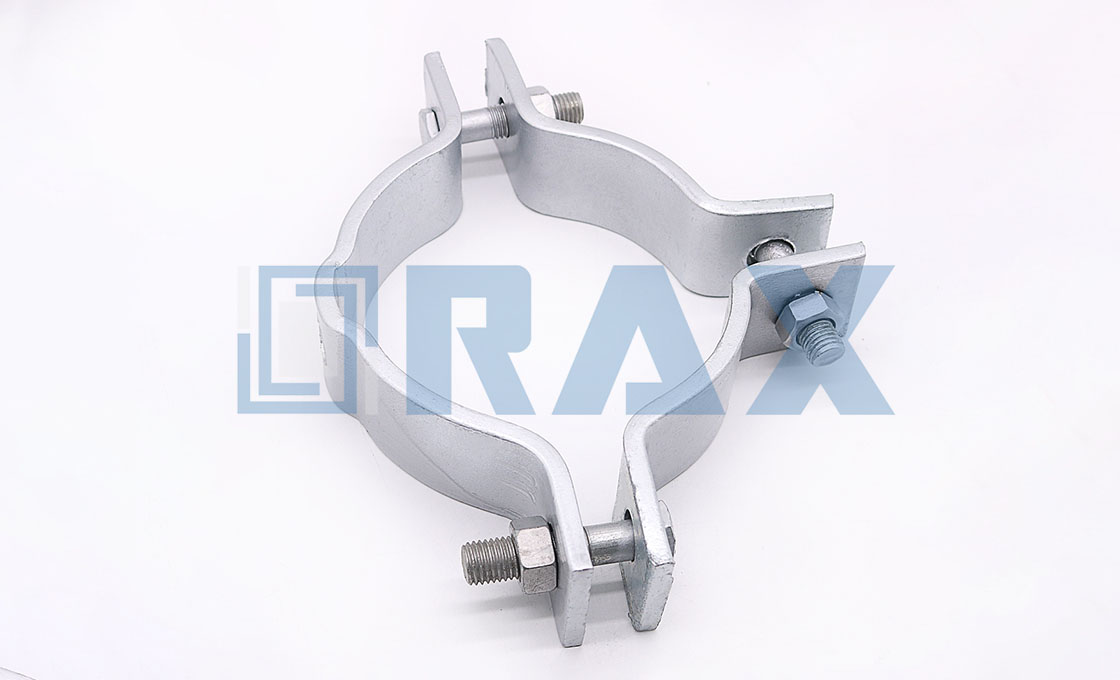

i. Turn Buckle

The turn buckle is available in three varieties which include:

I. Turn buckle eye/eye type: made of steel and threaded. It is also electro galvanized to offer a smooth finish. It has two ends with holes known as the eyes.

II. Turn buckle hook/hook type: made of steel and threaded on both sides. It is also passed through electro galvanization to make it have a fine finish.

Both ends have hooks that are used to attach to a different accessory.

III. Turn buckle hook/eye type: made of steel and threaded on the two ends. The two ends are different with one side having a hook and an eye on the other end.

It has also been electro galvanized to offer the perfect finish.

ii. Eye Rod

Eye rods are made of steel and can either be hot dip galvanized or electro galvanized to prevent corrosion.

It has a hole at one of its ends commonly referred to as the eye thus the name the eye rod.

It is an important component at the joints making it flexible and easy to move.

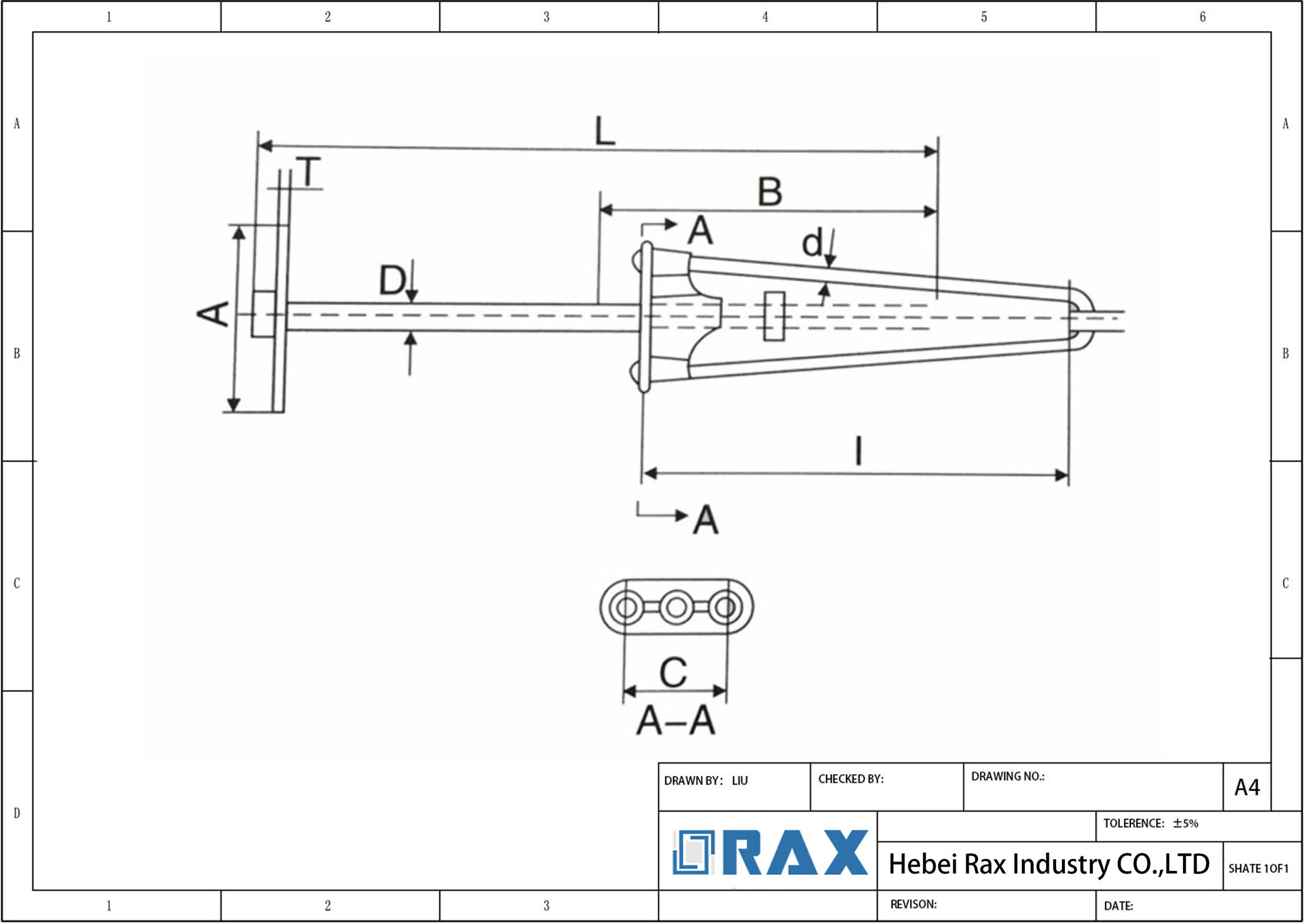

Technical Specification of Stay Rods

Depending on the wide range of specifications and demands from clients, stay rods come in different varieties.

They are major components in construction and the need for care and maintenance is negligible.

It is an efficient component due to its durability and ability to withstand tear and wear.

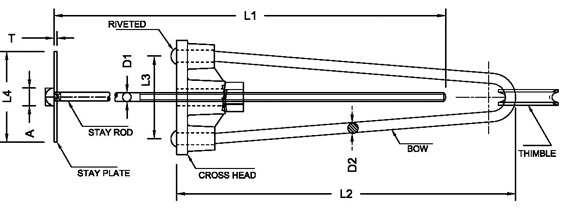

Technical specification of stay rod

Type of Material

The material used in making stay rods is usually steel on many occasions but there are other materials too.

Other materials include alloy steel, cast iron and carbon steel among other products that offer great strength and are durable.

The material is expected to be strong enough to withstand different weather conditions depending on the area it is used.

Corrosion is a major problem when it comes to materials like steel and iron.

To solve this problem, hot dip galvanization or electro galvanization is done to the said material.

The durability of the stay rod depends on the material used so it has to be handled properly.

Tensile strength

The kind of work performed by the stay rods involves the application of a lot of pressure on the rod or the stay set.

The material used has to be strong enough to withstand the high pressure from weight to high temperatures.

Quality compliance – ISO 1461

ISO 1461 is the standard used in rating the quality of metal for a particular use.

It was prepared by a technical committee ISO/TC 107, Metallic and other Inorganic coatings.

Under the sub-committee SC 4 Hot dip coatings (galvanized).

At the moment the third edition is in place canceling the second edition which was technically revised.

The revision of ISO 1461:1999 reflects the experience gained and includes a simplified presentation of procedures.

The changes in the new document are outlined below.

I. Refined scope of application of standards excluding welded or woven mesh products that have been continuously galvanized.

II. Addition of a definition for the welded seepage in the 3RD Clause.

III. The availability of zinc supply has brought about the addition of reference.

IV. The section on coating finish has also been improved by adding more information and explanatory notes.

V. The requirements for testing and sampling have also been made simple.

Dimension

The dimensions used in measuring the weight, diameter, and length vary according to the specifications given by the customer.

In most cases, weight is measured in kilograms while length and diameter are measured in millimeters.

The kind of work that the stay rod will be used for is a determinant of the kind of dimensions it will have.

The process of Making a Stay Rod

Depending on the type of material used in making the stay rod, most of them usually go through the same processes.

Technical drawing of stay rod

Technical drawing of stay rod

It is a very expensive method and is mostly left for industries to produce.

The process is also very risky to be done at home and protective gear must be on at all times.

- First, obtaining the relevant raw material used to make the stay rods for example steel, iron, or aluminum.

- The material is then melted in a furnace of very high temperatures usually above 1200 degrees Celsius. Furnace temperatures vary according to the material being used.

- The molten material is then channeled into different components which will provide the specified shape and size. Most of the specifications are from the customer and the intended purpose.

- Apart from that, the specification in making rods are usually computer generated.

- After the desired structure has been achieved, it can be taken through other processes to give it the preferred design. It can be bent, hammered, put under certain types of stress until it produces the right form.

- A complete design is given the final touch by either hot dip galvanization or electro galvanization. It will give the material a smooth finish with the desired color.

How to Install Stay Rods?

Stay rods are installed differently in accordance with the purpose it was intended to perform.

Since there are quite a number of stay rods of different designs, the user is advised to get an installation manual.

Apart from that, installation should be left to professionals to perform as they are more experienced.

- The tubular and bow types of stay rods go through the same procedure of installation.

- A very small part of the stay rod is usually left out while the rest of it is buried in the ground.

- Stay rods are expected to be at an angle of 45 degrees to the horizon.

- At one end there is a square rod and the other has between 100 – 300 mm length of thread.

- Stay bow goes across the screw as the ratchet nut fits the stay bow.

- The square space on the stay plate increases the strength. Burying it in the ground will stop the head of the stay rod from creeping.

Frequently Asked Questions (FAQs)

What is a stay rod?

Stay rod is also called stay set. It is a joined part that used to connect the stay wire to the ground anchor.

What are the types of stay rods?

According to the structure, stay rods are divided into two main types: the bow type and the tubular type.

Bow types of stays rods include:

- Stay bows

- Stay thimbles

- Stay plates

- Stay rods.

tubular types of stays rods include:

- Eye stay rod

- turn buckle stay rods

What does a stay rod set include?

One set stay rod includes: stay bow, stay rod, stay plate, stay thimble.

What is the main use of stay rods?

Stay rods support joined parts from collapsing under extreme pressure.

- In the electric field, it is used to stay tower structures and power poles.

2. In pole-line technology, different forms of stay rods are used in pole lines, distribution lines, and telecom lines.

How does the stay rod set assembly?

The stay rod will be 45 degrees around with the horizon. There is a square head on the stay rod, and at the other head of the stay rod, there is 100-300mm thread length. The stay bow will go across the screw, and the ratchet nut will fix the stay bow.

What is a stay rod set used together with?

The stay rod set is used together with the stay wire.

What needs attention when Installing a stay rod?

Stay rods are installed differently in accordance to the purpose it was intended to perform.

Since there are quite a number of stay rods of different designs, the user is advised to get an installation manual.

Apart from that, installation should be left to professionals to perform as they are more experienced.

Conclusion

Stay rods are important components of the different structures that we use in our daily activities.

They are however very vital in terms of securing them and installation.

In case a stay is to be replaced, a professional is to be contacted to help.

These products are available in the market for the consumer to choose from.

The customer also has the privilege of specifying the kind of product they would like to have.

Rax Industry is one of the manufacturing companies that welcome customer designs and are willing to fabricate them for you.