Guy Wire

Guy wire is a tension cable stranded by a few wires which are approximately circular in section and contain no weld, joint, or splice, it is lightweight and strong enough to stabilize and secure poles, towers, and other free-standing structures, especially in utility, antenna, and communications industries. Guy wire is also called stay wire or messenger wire.

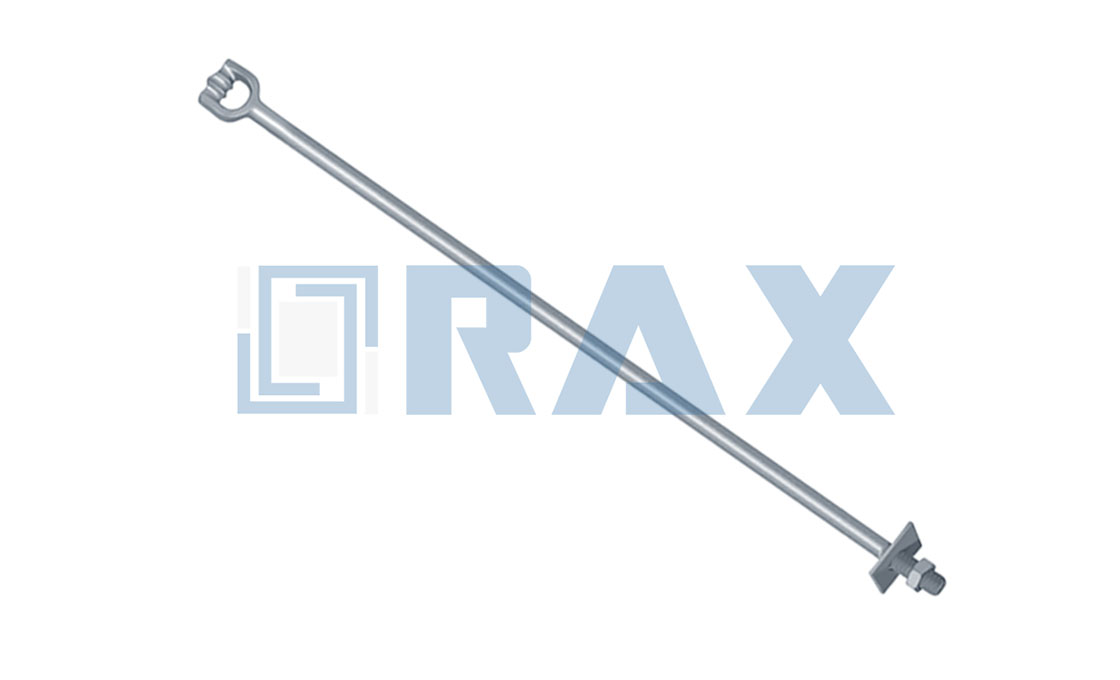

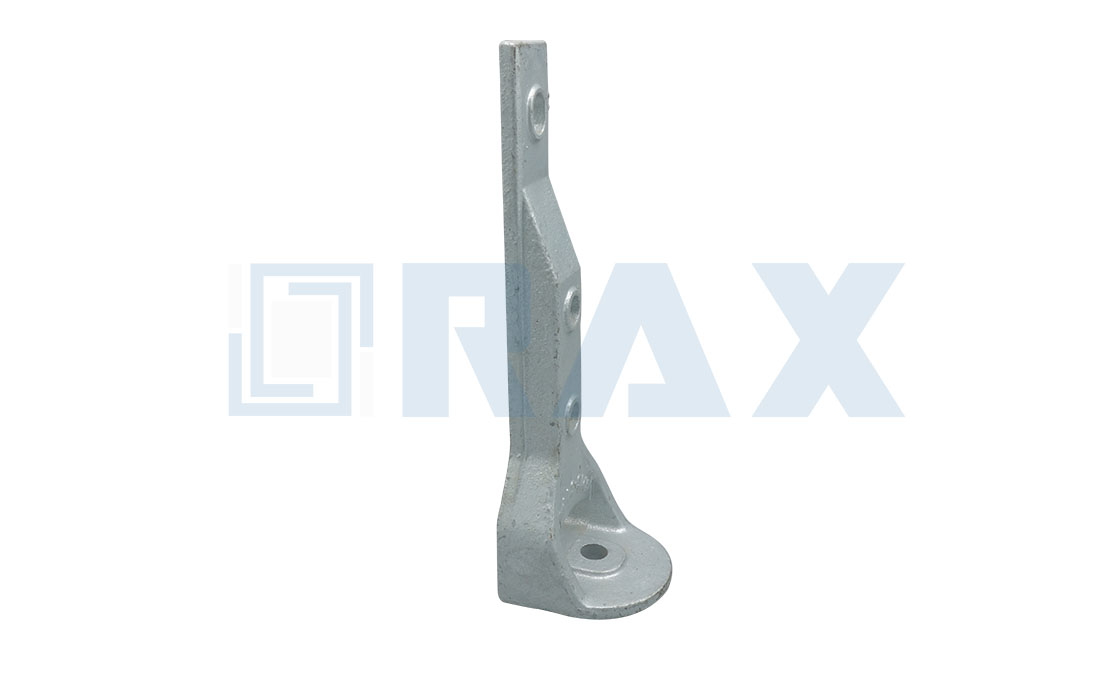

Guy wire is assembled with guy clamp, stay thimble, stay rod, stay pole bracket, anchor rod, and turnbuckle stay set. All of these stay accessories make up the pole line and telephone line to stable the pole and conductors.

Stay wire is manufactured perfectly and stable to withstand environmental stress during installation and throughout its lifetime.

All the galvanized steel wire is free from any scale, inequalities, spills, splits, or other defects. Each wire will be completely and smoothly galvanized before stranding.

As a leading guy wire manufacturer and supplier, Rax Industry can support you with all sizes of stay wire, We also can do OEM or ODM for you. If you have any inquiries, please do not hesitate to contact us.

| Description | Required Value |

| Size of Staywire: | 7/8 SWG |

| Diameter of Individual Wires: Nominal Maximum Minimum | 4.0mm 4.1mm 3.9mm |

| Nominal overall diameter of stranded staywire | 12.2m |

| Minimum ultimate tensile strength of individual wires | 70kgf/sq.mm |

| Maximum tensile strength of individual wires | 85kgf/sq.mm |

| Minimum percent elongation at rupture before stranding | 5% |

| Minimum percent elongation at rupture after stranding | 4.25% |

| Wrapping test for ductility: Turns on and off its own diameter | 8 |

| Lay ratio of finished strand | 19 to 21 |

| Minimum weight of zinc coating before stranding | 260g/sq.mm |

| Minimum weight of zinc coating after stranding | 254g/sq.mm |

| One minute dip tests: | |

| Single wire, before stranding | 4 |

| Single wire, after stranding | 3 |

| Singe wire, before stranding, wrapped on a mandrel 4 times its own diameter | 3 |

| Single wire, after stranding, wrapped on a mandrel 8 times its own diameter | 3 |

| Length of wire in finished coil: Standard Maximum Minimum | 100m 105m 95m |

TECHNICAL DATA SHEET FOR GUY WIRE | ||||||||||

| Sl. No. | Particulars | Unit | Bid | |||||||

| 1 | Name of Manufacturer | Rax Industry | ||||||||

| 2 | Material | GALVANIZED STEEL MESSENGER WIRE | ||||||||

| 3 | Reference Standard | ASTM A-475 | ||||||||

| 4 | No. of Strands & Wire Dia | 7/2.00 mm | ||||||||

| 5 | Overall diameter of Wire Strand | mm | 6.00 | |||||||

| 6 | Minimum Breaking Load | kN | 29.58 | |||||||

| 7 | Elongation | % | 4.00% | |||||||

| 8 | Lay Direction | LEFT HAND LAY | ||||||||

| 9 | Lay Ratio | Min: 12, Max: 16 | ||||||||

| 10 | Weight of Zinc Coating | g/m2 | 183 | |||||||

| 11 | Class of Coating | CLASS – ‘A’ | ||||||||

| 12 | Packing | IN WOODEN DRUMS | ||||||||

TECHNICAL DATA SHEET FOR GUY WIRE | ||||||||||||||

| Sl. No. | Particulars | Unit | Bid | |||||||||||

| 7/3.05 MM | 7/3.68 MM | 7/2.64 MM | ||||||||||||

| 1 | Name of Manufacturer | Rax Industry | ||||||||||||

| 2 | Material | GALVANIZED STEEL MESSENGER WIRE | ||||||||||||

| 3 | Reference Standard | ASTM A-475 | ||||||||||||

| 4 | No. of Strands & Wire Dia | 7/3.05 | 7/3.68 | 7/2.64 | ||||||||||

| 5 | Overall diameter of Wire Strand | mm | 9.52 | 11.11 | 7.94 | |||||||||

| 6 | Minimum Breaking Load | kN | 68.50 | 92.52 | 49.82 | |||||||||

| 7 | Elongation | % | 4.00% | |||||||||||

| 8 | Lay Direction | LEFT HAND LAY | ||||||||||||

| 9 | Lay Ratio | Min: 12, Max: 16 | ||||||||||||

| 10 | Weight of Zinc Coating | g/m2 | 259 | 275 | 244 | |||||||||

| 11 | Class of Coating | CLASS – ‘A’ | ||||||||||||

| 12 | Packing | IN WOODEN DRUMS | ||||||||||||

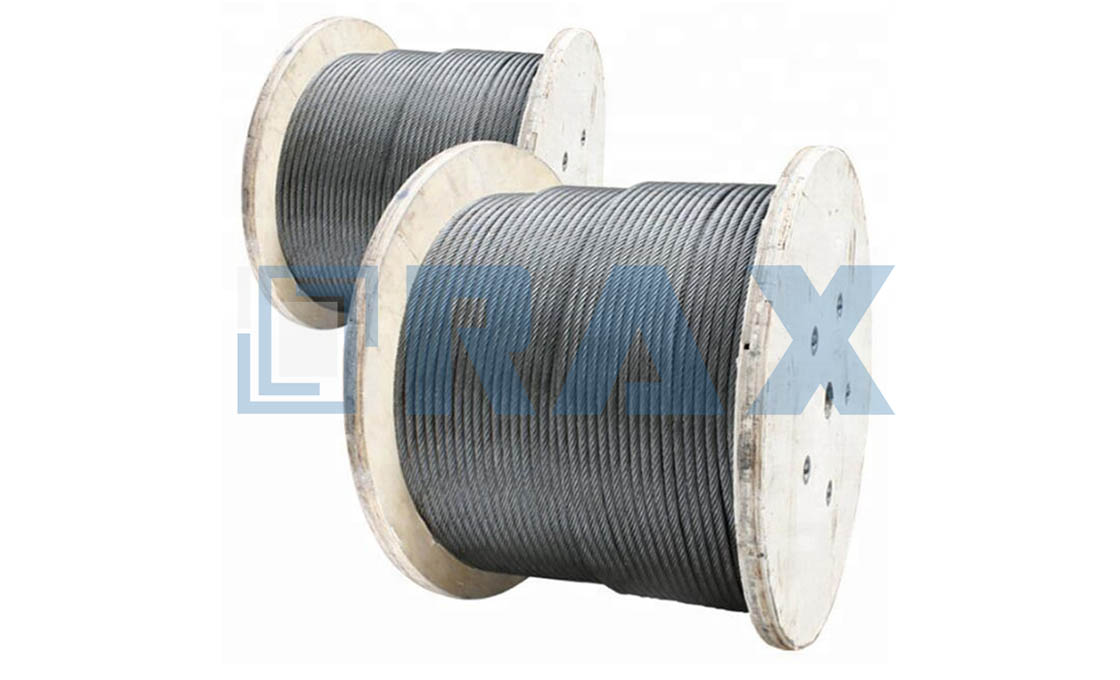

Stay wire Coils

Rax Industry standard packing for stay wire is smoothly and uniformly coiled in standard 100m coils with a tolerance of +5%. According to your different requirements, we can pack it in different lengths and marked clearly on the coil.

To protect the coils from damage during transportation, handling, or storage, the coils are lagged with woven bags. The stay wire coil has a minimum diameter of 520mm. we can design different sizes according to your requirements.

Guy Wire:The Complete Guide

The guy wire is of extra high strength grade based on ASTM A475 Standard Specification for Zinc-Coated Steel Wire Strand”.

The wire strands covered in this specification are commercially known to be 6M, 10M, and 16M all of which are seven-wire (7-wire) strand.

Guy Wire Material

The base metal is steel made by the open-heart, basic oxygen, or electric furnace process. It is of such quality and purity that when drawn to the specified size and coated with zinc, the finished strand and the individual wires will be of uniform quality and have the properties and characteristics as prescribed in ASTM A475.

The slab zinc from which the coating is derived will be any grade of zinc conforming to ASTM B6 “Specification for Zinc (Slab Zinc)”.

Guy Wire Physical Specification

Stranding

- Unless otherwise specified, the wire strand has a left lay. A left lay is defined as a counterclockwise twist away from the observer. All wires are stranded with uniform tension. Stranding is sufficiently close to ensure no appreciable reduction in diameter when stressed to 10% of the specified strength.

- The type of strand in this specification is 7-wire strand and consists of a center wire with a 6-wire layer concentrically twisted around it with a uniform pitch of not more than 16 times the specified nominal diameter of the strand.

- All wires in the strand lie naturally in their true positions in the completed strand. When the strand is cut the ends will remain in position or be readily returned by hand and then remain in position. This may be accompanied by any means or process such as pre-forming, post-forming, or form setting.

Joints and Splices

- Electric-welded butt joints made prior to the start of cold drawing of the guy wire are permitted.

- In the 7-wire strand, joints made in individual finished wires are acceptable provided there is not more than one joint in any 45.7 m (150 ft.) section of the completed strand and the location of each joint is marked on the strand with paint or some distinguishing marks.

Weight of Coating

- The weight of the zinc coating in grams per square meter of the uncoated wire surface is not less than 244 for the 6M strand, 259 for the 10M strand and 275 for the 16M strand.

- The weight of zinc coating is determined by the stripping test in accordance with ASTM Test Method A90 “Test Method for Weight of Coating on Zinc-coated (Galvanized) Iron or Steel Articles”.

Adherence of Coating

- The zinc coated wire is capable of being wrapped at a rate not exceeding fifteen (15) turns per minute in a close helix of at least two turns around a cylindrical mandrel equal to three times the nominal diameter of the wire under test. This process should not allow cracking or flaking of the zinc coating to such an extent that any zinc can be removed by rubbing with bare hands.

Note: Loosening or detachment during the adhesion test of superficially small particles of zinc, formed by mechanical polishing of the surface of zinc-coated wire, is not considered a cause for rejection.

Finish

- The zinc-coated wire is free from imperfections not consistent with good commercial practice. The zinc coating is continuous and of reasonably uniform thickness.

Guy Wire Dimensional Specification

- The nominal diameter of a 6M wire strand is94 mm while that of a 10M strand is 9.52 mm and 11.11 mm for the 16M wire strand.

- The nominal diameter of each zinc-coated

- 6M wire is64 mm.

- For a 10M wire it is05 mm and

- 68 mm for 16M wire.

- The permissible variations for 6M, 10M, and 16M strand is ± 0.10 mm, ± 0.10 mm, and ± 0.13 mm respectively.

Note: The permissible variations in the diameter of individual zinc coated wires for 6M, 10M, & 16M strands are ± 0.10 mm, ± 0.10 mm and ± 0.13 mm respectively.

- 7 – 3.05 mm (0.120 in)

- 7 – 3.68 mm (0.145 in)

- 7 – 2.64 mm (0.104 in)

- 52 mm (3/8 in)

- 11 mm (7/16 in)

- 94 mm (5/16 in)

Guy Wire Packing and Marking

- Wire strand is furnished in standard lengths and in compact coils or on reels as specified in Sections 7.2 and 7.3. Only one length of the strand is furnished in each coil or on each reel.

- Standard lengths of the wire strand are as follows: 76, 152, 304, 760, and 1520 meters.

- Standard practice is to furnish all 16M (11.11 mm) and over in diameter on reels in lengths of 304m (1000 ft) and over. Strand lengths of less than 304 m are regularly furnished in coils.

- Each coil or reel has a strong weather-resistant tag securely fastened to it showing the length, nominal diameter, number of wires, the grade of the strand, type or class of coating, ASTM A475, and the name or mark of the manufacturer. If additional information is required on the tag, it is so specified at the time of purchase.

Guy Wire Finished

- The finished product meets all the minimum requirements set forth in this specification.

- Telecommunications Technical Standards for Outside Plant (OSP Standards), Part II. National Telecommunications Commission. Republic of the Philippines.

- ASTM A475 – 89 “Standard Specification for Zinc-Coated Steel Wire Strand”. American Standard for Testing and Materials. ASTM Committee A-5 on Metallic Coated Iron and Steel Products. April 1989.

ASTM A 90/A90M – 93 “Test Method for Weight [Mass] of Coating on Iron and Steel Articles with Zinc or Zinc-Alloy Coatings”. American Standard for Testing and Materials. 1993.

TECHNICAL DATA SHEET FOR GUY WIRE

| Sl. No. | Particulars | Unit | Bid | ||

| 7/3.05 7/3.68 MM MM | 7/2.64 MM | ||||

| 2 | Material | GALVANIZED STEEL GUY WIRE | |||

| 3 | Reference Standard | ASTM A-475 | |||

| 4 | No. of Strands & Wire Dia | 7/3.05 | 7/3.68 | 7/2.64 | |

| 5 | The overall diameter of Wire Strand | mm | 9.52 | 11.11 | 7.94 |

| 6 | Minimum Breaking Load | kN | 68.50 | 92.52 | 49.82 |

| 7 | Elongation | % | 4.00% | ||

| 8 | Lay Direction | LEFT HAND LAY | |||

| 9 | Lay Ratio | Min: 12, Max: 16 | |||

| 10 | Weight of Zinc Coating | g/m2 | 259 | 275 | 244 |

| 11 | Class of Coating | CLASS – ‘A’ | |||

| 12 | Packing | IN WOODEN DRUMS | |||

Galvanized Steel Wire for Sale

Rax Industry is the top guy wire manufacturer in China, our team produces the galvanized steel wire in such a way that an evenly distributed pull is applied at the ends of the completed stand, each wire will take an equal share of the pull.

The lay of the wires can be left or right-handed.

All the guy wire raw materials are according to BS 183 which is a specification for general purpose galvanized steel wire. The finished guy wire was tested according to BS 443. On the BS443, It elucidates the requirement of the testing zinc coating on steel wire and of quality requirements.

The widely used stay wire is stranded galvanized steel wire, comprising seven wires, each having a 4.0mm nominal diameter.

Are you worried to use the guy wire in localities close to the sea or where severe corrosion conditions? Rax Industry guy wire is your best choice.

Rax Industry stay wire can work on the coastal area, even in the environment, onshore winds are frequently salt laden. In the exposed, polluted, salty, or corrosive environment, Rax Industry guy wire performs without dust and broken.

Rax Industry stays wire is used on 33kv,11kv, and LV lines. The minimum failure load of guy wire is not less than 63kn.

Frequently Asked Questions (FAQs)

What is a guy wire?

Guy wire is a galvanized steel wire strand that used in the electricity industry mainly for sustaining mechanical load on the electric pole or tower. It is also called stay wire, messenger wire or guide wire.

What is the function of a stay wire?

Stay wire provides a mechanical strength or support to the electrical pole and tower, protecting the tower from falling down due to heavy load on it.

What fittings are usually used with guy wires?

Guy wire is assembled with guy clamp, stay thimble, stay rod, stay pole bracket, turnbuckle stay set and so on