Are you looking for a reliable way to secure structures to the ground? Penetrator earth anchors offer an innovative solution, combining exceptional holding power with easy installation. This comprehensive guide will walk you through everything you need to know about these versatile anchoring systems.

Table of Contents

- 1 What is a Penetrator Earth Anchor?

- 2 What Makes Penetrator Earth Anchors Your Best Choice?

- 3 How Do You Install Penetrator Anchors Correctly?

- 4 Which Projects Can Benefit from Penetrator Anchors?

- 5 How Much Weight Can Penetrator Anchors Hold?

- 6 What Are The Best Soil Conditions for Installation?

- 7 How Much Does a Penetrator Anchor Cost?

- 8 What Are The Alternative Products to Penetrator Earth Anchors?

- 9 Where to Buy Penetrator Earth Anchors

- 10 A Leading Manufacturer

- 11 Frequently Asked Questions

What is a Penetrator Earth Anchor?

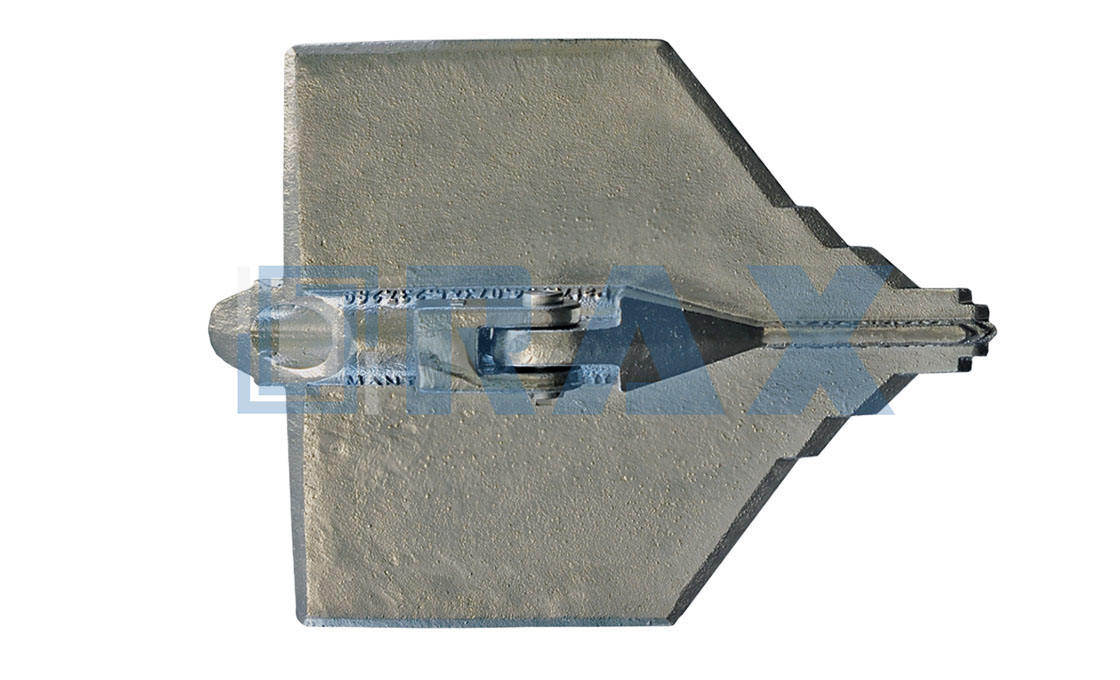

A Penetrator earth anchor, also known as an earth screw anchor or American Ground Screw, is a specialized anchoring device designed to secure structures to the ground. These anchors consist of a helical-shaped blade attached to a central shaft, creating a robust underground anchoring point when installed.

How It Works The anchor’s unique mechanism operates in two phases:

- Installation Phase: The helical blade drives into the soil like a screw

- Loading Phase: When tension is applied, the blade rotates perpendicular to the pull direction, creating a strong resistance against the compacted soil

What Makes Penetrator Earth Anchors Your Best Choice?

When it comes to ground anchoring solutions, Penetrator anchors stand out due to their unique design and robust construction. These anchors are crafted from heat-treated 356 aluminum, engineered specifically to excel in diverse ground conditions from standard soil to challenging underwater environments.

Superior Design Features

- Heat-treated aluminum construction for maximum durability

- Versatile lengths ranging from 9′ to 46′

- Impressive holding capacity of 2,500 to 14,000 lbs

- Multi-surface compatibility including soil, sand, and asphalt

How Do You Install Penetrator Anchors Correctly?

Success with Penetrator earth anchors largely depends on proper installation techniques. Let’s explore the most effective methods to ensure your anchor provides maximum holding power.

Professional Installation Methods

- High-efficiency portable impact wrench installation

- Machine PTO drive with specialized attachments

- Manual installation using a ratcheting T-Handle

For challenging installations in dense soil conditions, consider pre-drilling a 1-inch pilot hole. Each anchor features a precision-engineered hexagonal head designed to work seamlessly with a 1-inch socket, ensuring smooth and accurate installation.

Which Projects Can Benefit from Penetrator Anchors?

Understanding the versatility of these anchors helps you make informed decisions for your specific needs. These anchors excel in both professional and recreational applications.

Construction Industry Solutions

- Temporary bracing systems for metal building construction

- Quick-deploy portable structure securing

- Temporary facility foundation support

Residential and Recreational Applications

- Playground equipment and swing set anchoring

- Garden shed and storage unit securing

- Sports equipment stabilization

- Outdoor event structure fastening

How Much Weight Can Penetrator Anchors Hold?

Understanding load capacity is crucial for safe and effective anchor deployment. Penetrator earth anchors demonstrate impressive holding power that varies based on installation conditions and anchor specifications.

Load Capacity Breakdown The following factors influence maximum holding strength:

- Soil density and type

- Installation depth

- Anchor size selection

- Pull angle direction

A properly installed Penetrator anchor can achieve remarkable holding power:

- Small models: 2,500 – 4,000 lbs

- Medium models: 5,000 – 8,000 lbs

- Large models: 10,000 – 14,000 lbs

What Are The Best Soil Conditions for Installation?

Soil conditions significantly impact anchor performance and installation ease. Understanding your ground composition helps select the optimal installation method and anchor type.

Ideal Ground Conditions Different soil types require specific approaches:

| Soil Type | Installation Notes | Expected Performance |

|---|---|---|

| Sandy Soil | Requires deeper installation | Good holding in compact conditions |

| Clay | May need pre-drilling | Excellent holding power |

| Loam | Standard installation | Very good performance |

| Rocky Ground | Pre-drilling recommended | Variable holding strength |

“Proper soil assessment and installation technique are crucial for achieving optimal anchor performance and ensuring long-term stability of your secured structures.”

How Much Does a Penetrator Anchor Cost?

The cost of Penetrator earth anchors varies significantly based on several key factors:

Size and Model Impact

- Small anchors (9-10 inch): $7-30

- Medium anchors (18-26 inch): $30-120

- Large anchors (36-46 inch): $120-160

Factors Affecting Price

- Installation depth requirements

- Holding capacity needs

- Material type (heat-treated 356 aluminum)

- Quantity ordered (bulk discounts available)

- Additional accessories needed

Additional Cost Considerations

- Installation tools and equipment

- Shipping costs for heavy-duty models

- Optional accessories like tie-off rings

- Special brackets for specific applications

“While initial costs may seem high, professionals consider these anchors a cost-effective investment for structural stability compared to traditional foundation methods.”

Earth anchors are ground-securing devices designed to provide stability for various structures without requiring concrete foundations. While Penetrator earth anchors use a helical design, several alternative products offer different approaches to ground anchoring.

What Are The Alternative Products to Penetrator Earth Anchors?

Several ground anchor types offer different solutions based on soil conditions and project requirements.

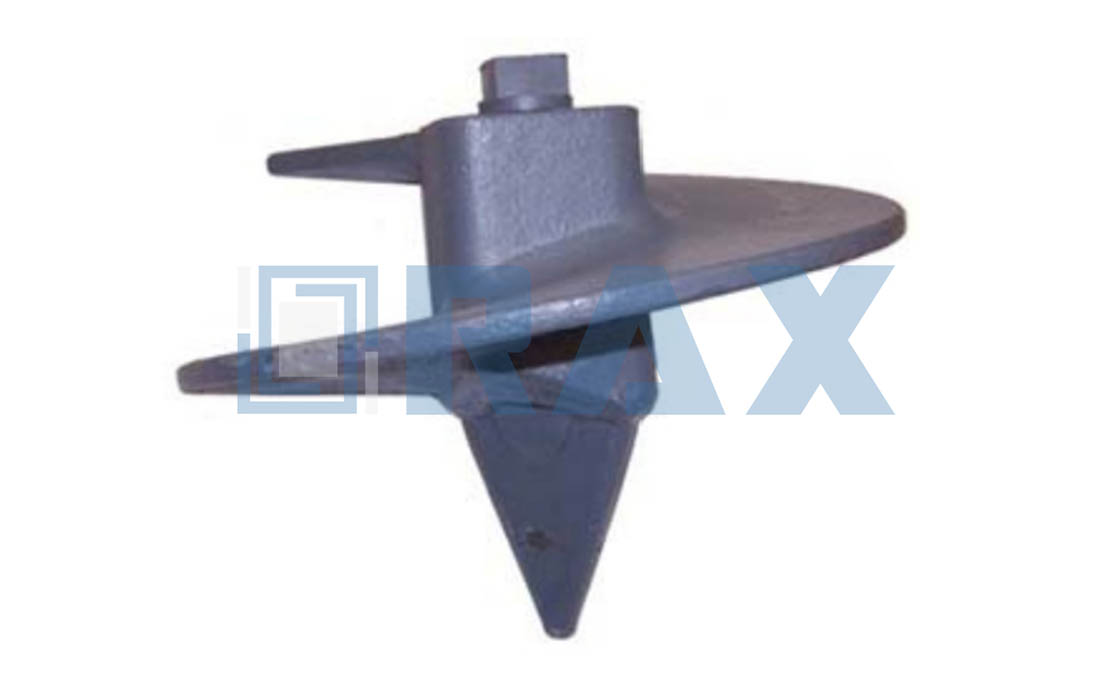

No-Wrench Screw Anchor

This specialized earth anchor consists of a galvanized steel threaded rod with an upset hex and either single or double helix attached to a square steel hub. It features a forged-eye design that allows for both machine and hand installation without requiring special wrenches. The anchor includes a forged eye for guy wire attachment and works effectively in loose to medium-dense soils.

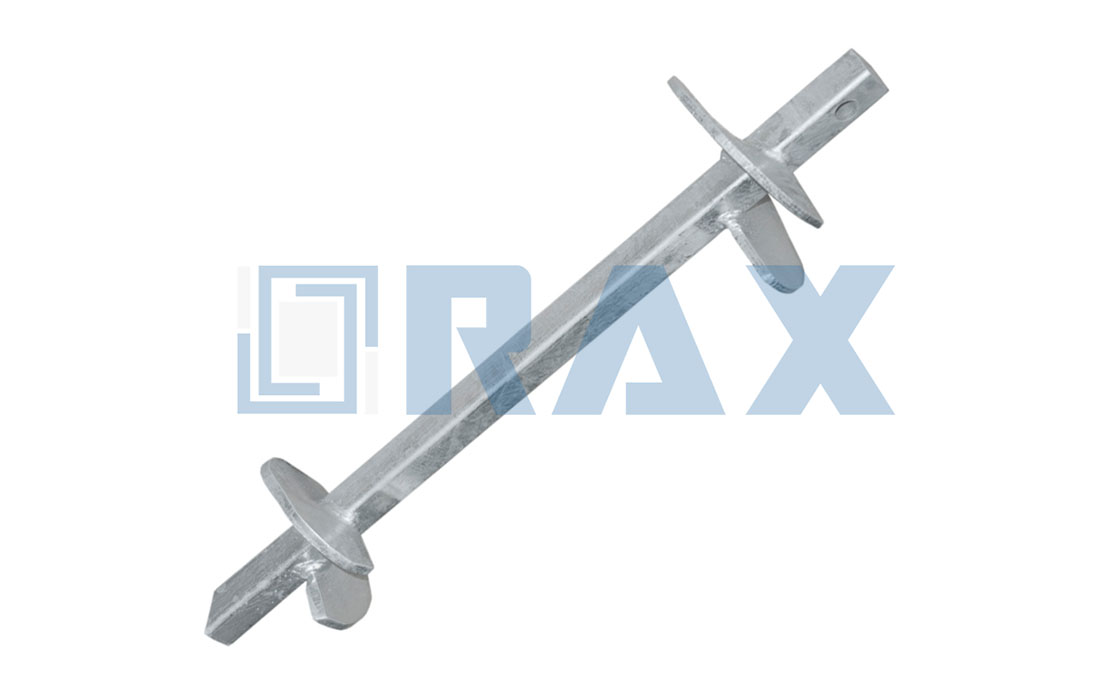

Power Hub Screw Anchor

These versatile anchors utilize a rotating installation method and are designed for a wide range of ground conditions. The system provides strong structural support through its helical design, making it particularly suitable for securing various types of equipment and structures. Their versatility makes them valuable for multiple applications across different soil types.

Square/ Round Shaft Helical Anchor

These anchors are specifically engineered for weak soil conditions where higher holding capacities are required. The system consists of three main galvanized components: a lead section with helical plates, extension shafts, and a guy adapter. The shaft design allows for deeper installation by adding extension shafts, making it particularly effective in challenging soil conditions.

Duckbill Anchors

These anchors operate like toggle bolts in soil, using a unique mechanical principle. When driven into the ground, the anchor body remains vertical. Upon applying tension to the cable, the anchor rotates 90 degrees perpendicular to the pull direction, creating a strong anchoring point in undisturbed soil[1]. This design allows for installation without digging or creating significant soil disturbance.

Manta Ray Utility Anchors

These are driven tipping plate anchors that represent a breakthrough in anchoring technology. The system uses a plate that is driven into the ground and then rotated to create resistance. Unlike traditional anchors, Manta Ray anchors can be proof-loaded immediately after installation to verify their exact holding capacity, eliminating guesswork in installation.

Where to Buy Penetrator Earth Anchors

Direct from Manufacturer

- Offers complete product range and technical support

- Provides custom solutions and expert guidance

- Direct shipping available

- Best for bulk orders and professional contractors

Home Improvement Retailers

- Features various models and sizes

- Quick shipping options

- Customer reviews available

- Convenient for individual purchases

- Easy returns and customer service

Specialty Construction Suppliers

- Professional construction supply stores

- Offers technical expertise and advice

- Local support and service

- Installation equipment available

- Ideal for contractors and commercial buyers

Agricultural and Farm Supply Stores

- Stocks common sizes for agricultural use

- Local availability

- Hands-on product inspection possible

- Often provides practical application advice

A Leading Manufacturer

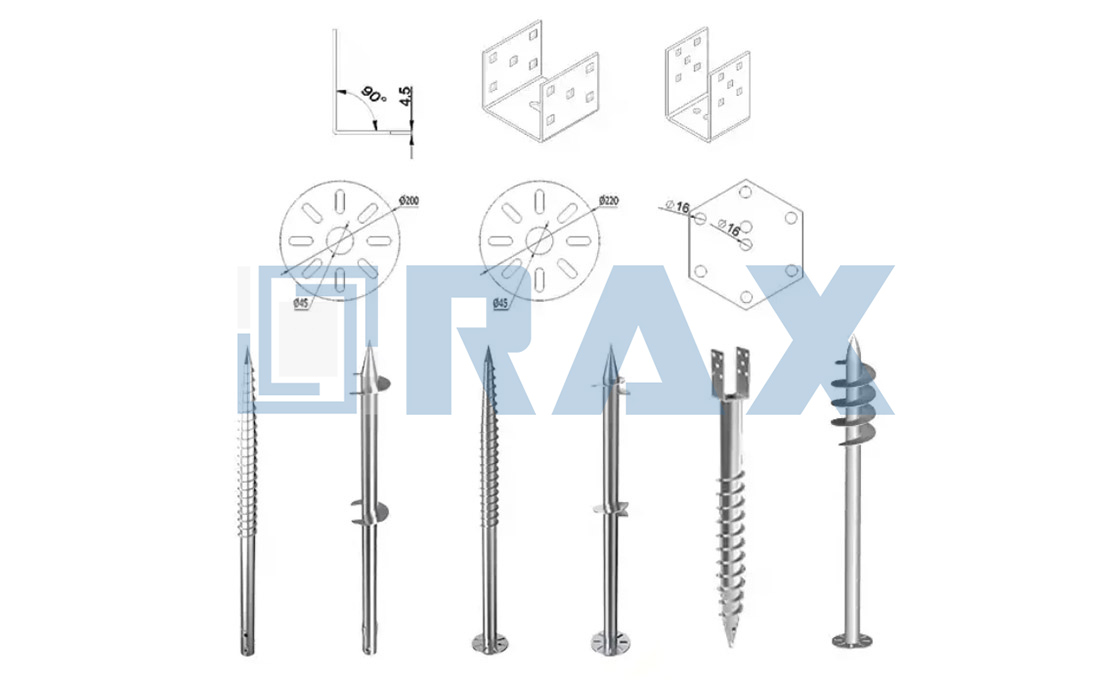

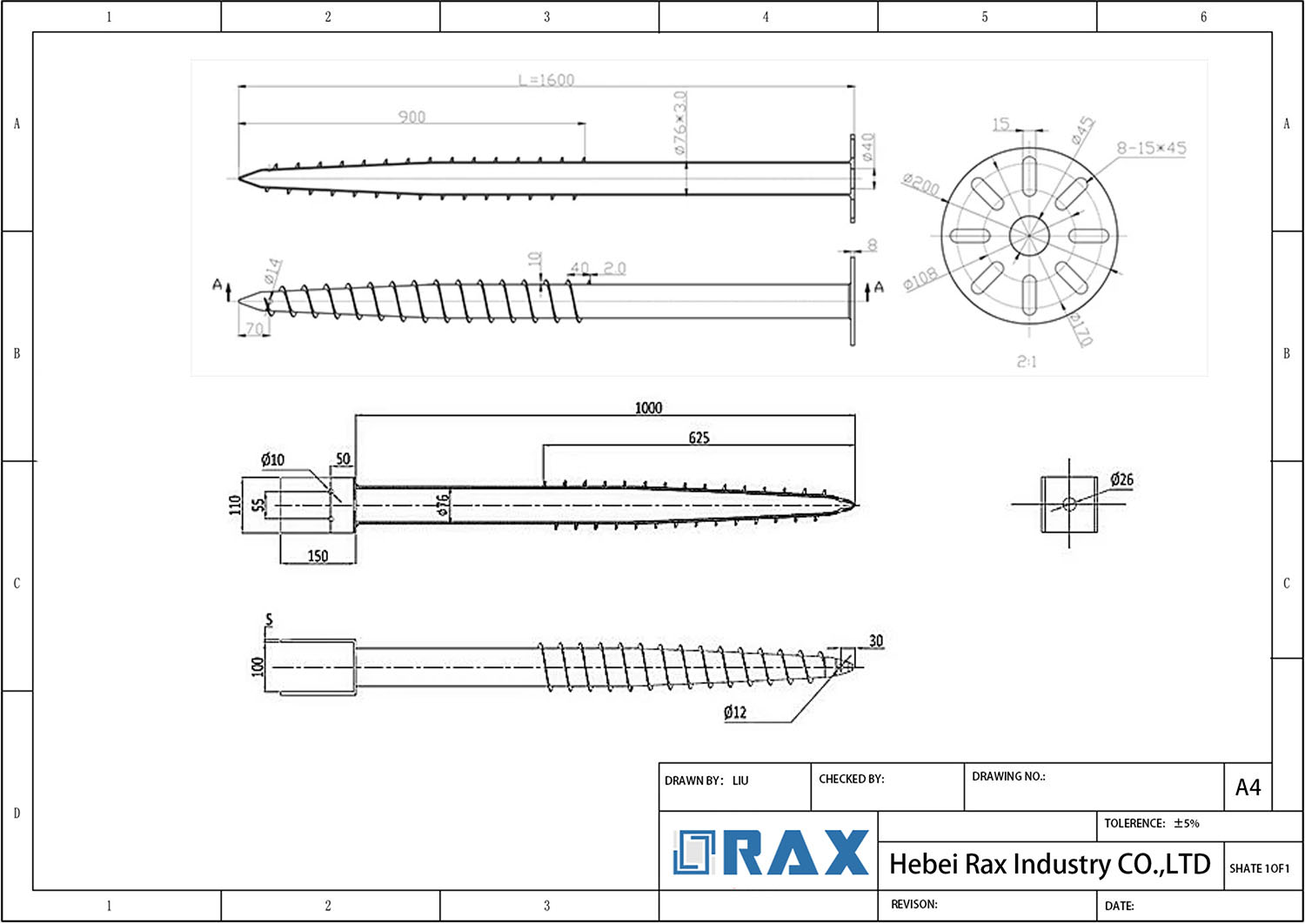

RAX Industry, a Chinese manufacturer since 2003, offers customizable earth anchors with professional manufacturing capabilities.

- Customization Options: Various sizes, shapes, and specifications available.

- Quality Materials: Hot-dip galvanized steel meeting ASTM specifications.

- 21+ Years Experience: Specializes in pole line hardware and power equipment.

Frequently Asked Questions

What is a Penetrator Earth Anchor?

A reusable screw anchor made of heat-treated 356 aluminum, designed for securing structures to the ground with superior pullout resistance.

How much holding power do they provide?

Holding capacity ranges from 2,500 to 14,000 pounds, depending on soil conditions and anchor size.

What are the installation methods?

Three main installation methods are available:

- Portable impact wrench

- Machine PTO drive with suitable attachments

- Manual ratcheting T-Handle

What applications are they suitable for?

- Sheds and portable structures

- Tarps and canopies

- Trees and mailboxes

- Antennas and towers

- Wind turbines

- Playground equipment

What affects the anchor’s performance?

- Soil’s moisture content and compaction

- Earth anchor’s root penetration

- Installation method

- Pullout load angle

- Site-specific conditions

How do you choose the right size?

The choice depends on:

- Required holding strength

- Soil conditions

- Installation depth

- Flight width (wider flights provide more holding power)

- Application requirements

Do they work in all soil types?

Performance varies by soil class:

- Class 1 (Hard Pan Soil): Best performance

- Class 2 (Dense Sand & Gravel): Good performance

- Class 3 (Medium Sandy Gravel): Moderate performance

- Class 4 (Loose Sand): Limited performance

Is pre-drilling required? Pre-drilling is recommended for:

- Asphalt installation

- Gravel surfaces

- Hard clay

- Rocky soil

- Areas with underground obstacles