Overhead Line Fitting

Overhead line fitting is also called overhead line hardware or overhead line accessories.

The overhead line fittings include a wide range of steel fittings that are used to construct the overhead line.

Rax Industry overhead line fittings are for use in electricity distribution networks including 11/33kv overhead lines and associated substations.

Rax Industry is a professional overhead line fitting manufacturer, most of our fittings are hot-dip galvanized coatings according to ISO1461.

Top Overhead Line Fitting Manufacturer and Supplier

Rax Industry overhead line fitting is designed to hang, connect or protect conductors or insulators.

At the dead-end pole, Rax Industry overhead line fitting is all kinds of parts which used to connect the stay wire.

According to the function, Rax Industry overhead line fittings can be divided into:

- String hardware

- Suspension clamp

- Tension clamp

- Splicing fitting

- Protective fitting

- Dead end fitting

Tips for overhead line fittings

- Why is overhead line fittings important?

- Types of overhead line fittings

- How to produce overhead line fittings

- Overhead Powerline Fittings Guide

- 1): What are Overhead Line Fittings?

- 2): What are the Functions of Overhead Line Fittings?

- 3): Properties Overhead Line Fittings

- 4): Common Overhead Line Fittings

- 5): Choosing the Best Overhead Lines Fittings

- 6): Conclusion

Why is overhead line fittings important?

Overhead Line Fitting

Overhead lines basically refer to posts or columns that are used in supporting overhead public utilities. These utilities include overhead lines, overhead cables, streetlights, transformers, as well as fiber optic cables.

These overhead lines are required for insulating these utilities from touching the ground and also for ensuring that vehicles or people do not interrupt them or get affected by them.

Owing to the fact that these overhead lines ensure the safety of the people and also insulate various overhead utilities, they need to be made from materials that are durable and strong.

Overhead line fittings are also known to include fasteners, which enable them to support cables comprehensively. These fasteners, which are also known as crossover clamps, are made in different dimensions, to support different sized cables and are usually used at important junctions that occur between many cables, to help stabilize them.

let me explain each type of overhead line fitting one by one:

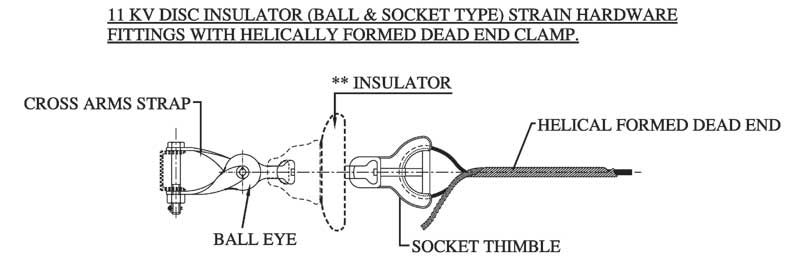

string hardware

Rax Industry string hardware is comprised of the following components:

Tension dead end clamp

Anchor shackle

Ball eye

Socket tongue

The tension dead end clamp is made of cast iron instead of aluminum alloy.

All of the components are hot dip galvanized steel of Min UTS 60KN for 33kv overhead line.

Suspension clamps were signed for use on Aluminium Conductor steel reinforced (ACSR) to hang the ACSR to the insulator fitting.

3 Bolt tension dead-end clamps for line 100mm2(ACSR and AAAC) conductor is for fastening of the M.V conductors to the tension insulators. The tension clamps are made of aluminum alloy of min ultimate tensile strength (U.T.S) 60KN. The U bolts, nuts, washers are hot dip galvanized steel. The cotter pins are stainless steel.

String hardware

When the single insulator connected into an insulator chain, Rax Industry string hardware is used to joint one or two insulator chains.

The complete set which used to joint one single insulator chain is as below:

- Ball hook

- Ball socket

The dimensions of ball socket and ball eye test according to IEC60120.

- Tension clamp

- U BOLT

The string hardware which used to connect the insulator chains on to the cross arm or assemble the earth wire on the pole or tower is as below:

- Yoke plate

- U Clevis

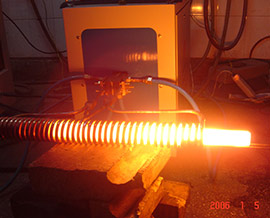

How to produce overhead line fittings

Rax Industry as the best electrical overhead line material manufacturer ensures that all the raw material is of the best quality and confirms the latest BS standards.

There are many processes to make each type of overhead line fitting. For the ball eye, ball hook and U clevis, the main process is drop forged. For the cross arm, pole band and yoke plate, the main process is cold forming and pressing.

For the tension clamp and suspension clamp, the main process is casting.

To make every step very well, Rax Industry successfully passed the loading test and dimension test, also the Galvanizing test.

Overhead Powerline Fittings Guide

An overhead power line is not complete unless it has a set of line fittings.

The overhead line fittings ensure the overhead line operates as usual without any hitches.

They are usually attached to different components of the overhead power line to perform their respective functions.

In other words, overhead line fittings for insulators are different from the overhead lines for the conductors.

For this reason, you need to buy the right overhead accessory for the specific component of the overhead lines.

What are Overhead Line Fittings?

Overhead line fittings are basically accessories that are used to attach one component of an overhead power line into another component or unit.

For instance, a fitting can connect the conductor to the tension strings.

Other fittings are attached to the insulator or even to the same conductor to perform a different role.

What are the Functions of Overhead Line Fittings?

Probably you are wondering about the specific roles that are played by overhead line fittings.

Or are they just used to add aesthetic value to the power lines?

To give you a better understanding, here are some of the critical functions that are performed by the power fittings:

-To connect the conductor and the insulator to the poles or tower

-To protect the conductor and the insulator from stress and other mechanical forces

-To streamline the transfer of electric loads in a conductor

-To secure the cable and the conductor through the slip-hole

As you can see, the accessories mainly play a supporting role.

Theirs is to ensure that the main components of the overhead lines work smoothly as expected.

Properties Overhead Line Fittings

Before being supplied to the market, overhead line fittings must undergo a series of tests to ensure that they meet certain standards.

These standards are what define the properties of the accessories.

Of course, there are several reasons why this should be done.

First, the fittings will be exposed to vagaries of nature such as wind, rain, excess temperatures among others.

The tests are done to ensure that the fittings can withstand such conditions.

The second reason is to test the mechanics of the fittings.

Since the fittings will be connected to other components, there is a dire need to ensure that there is a seamless connection between all the components.

So, what are some of the properties that define the quality of overhead line fittings?

Material Properties of Overhead Line Fittings

There are certain requirements that define the ideal material of an overhead power line accessory.

One of them is hardness.

The material should be hard enough to survive any physical abrasions.

It should not bend or even break so easily when hit by an object.

Also, the materials should not corrode easily when scratched.

The physical property applies to all the overhead line fittings and their components regardless of their specific functions.

To achieve the highest standards, most overhead line accessories are made of steel and galvanized aluminum.

This is because these two metals are known for their immense strength and resistivity.

In order to counter the effect of rusting, the materials are galvanized.

The material of the fitting should have some level of thickness so as to give some allowance in case of the corrosion.

2.Design Properties of the Overhead Line Fittings

When you see the term design, what is the first thing that will come into your mind?

To most of us, a design is usually associated with the shape and structural organization of an object.

It dictates how overhead line fittings relate to other essential components of an overhead power line.

There are certain design requirements that an accessory should meet.

First, the design should allow the accessory to move along the insulator or conductor freely.

There should be no frictional force or any other resistance forces that hinder the movement of the fitting.

The dimensions of an accessory should be precise and accurate.

This will allow the accessory to attach itself easily to the conductor without forcing you to make any adjustments.

In terms of the dimension, you should consider the diameter and even the length of the fitting.

The accuracy of the dimension can also prevent the accessory from becoming loose and falling off the conductor

You may also need to consider the weight of the accessory.

Do you know that an overweight fitting can cause fatigue damages to the conductor?

Another design factor that you need to take care of is the allowance angle at which the accessory can swing from the conductor.

For example, a counterweight stirrup of a suspension clamp has an allowance of 45°.

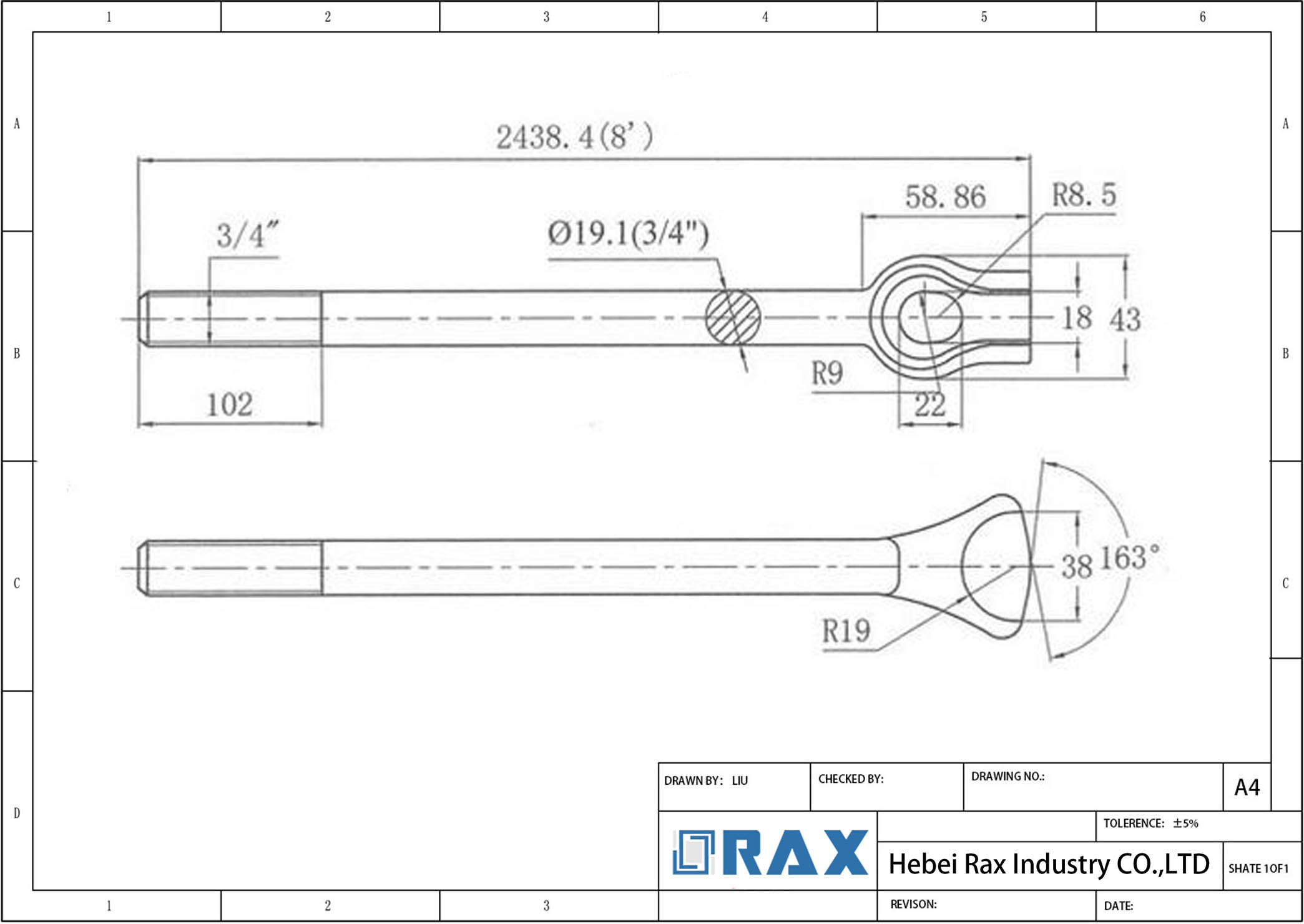

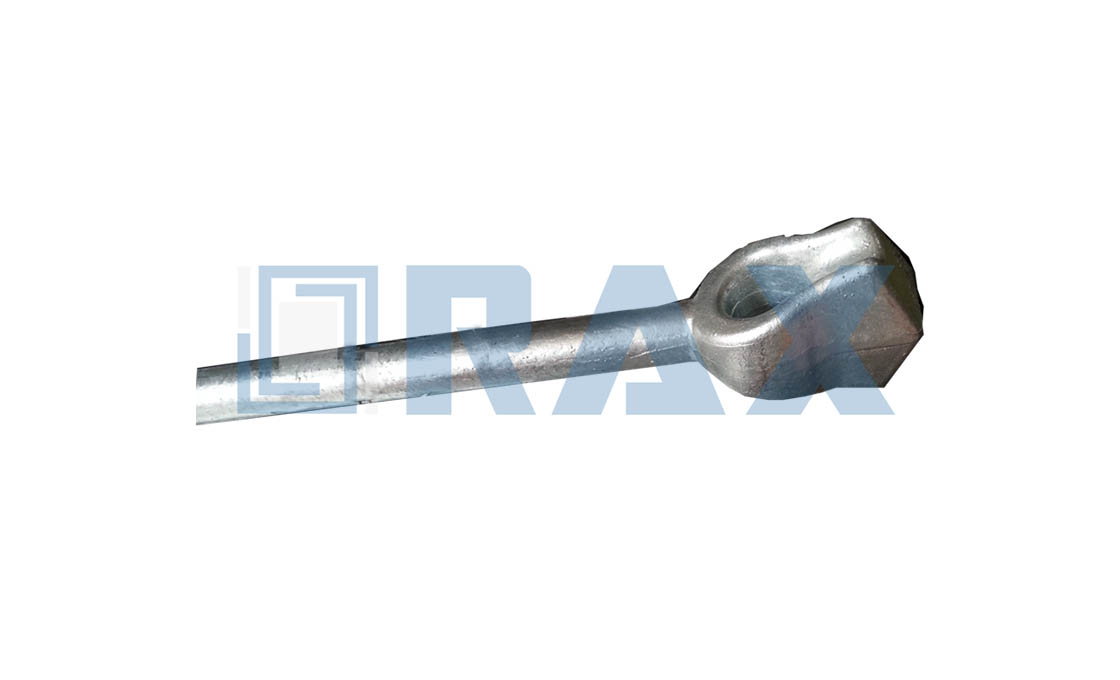

Anchor Rod Drawing

3.Mechanical Properties of the Overhead Line Fittings

Mechanical properties define how overhead fittings work.

They also dictate the correlation between the fittings and the conductor.

The first mechanical property that needs to be considered is the turning angle of the accessory.

The fitting should have a well-defined angle at which it can turn without breaking or showing any signs of deformation.

Another mechanical property that you should consider is the amount of force which the accessory will exert on the conductor.

The force should be reasonable. However, it should not be too much such that it can cause physical damage to the conductor.

Electrical Properties of Overhead Line Fittings

Since the overhead lines are for transmitting electricity, the fittings should have several electrical properties.

The first property is the ability to withstand the fault current.

This is the current that flows through the conductor when there is a fault.

It usually happens when the conductors short-circuit each other.

The second property is the accessory should not cause any hysteresis loss.

This is the current loss that is usually caused by magnetic effects.

Common Overhead Line Fittings

So, which are these overhead fittings that we keep talking about?

Here is a breakdown of the most important accessories for overhead lines that you need to buy.

1. Suspension clamp for overhead lines

Suspension Clamp

A suspension clamp is an overhead hardware that clamps a conductor or cable longitudinally to the pole.

The arms of the clamp extend outwards to whichever direction you would like the cable to.

Even though the clamp holds on tight to the cable, it still allows it to oscillate freely along with it but within a well-defined limit.

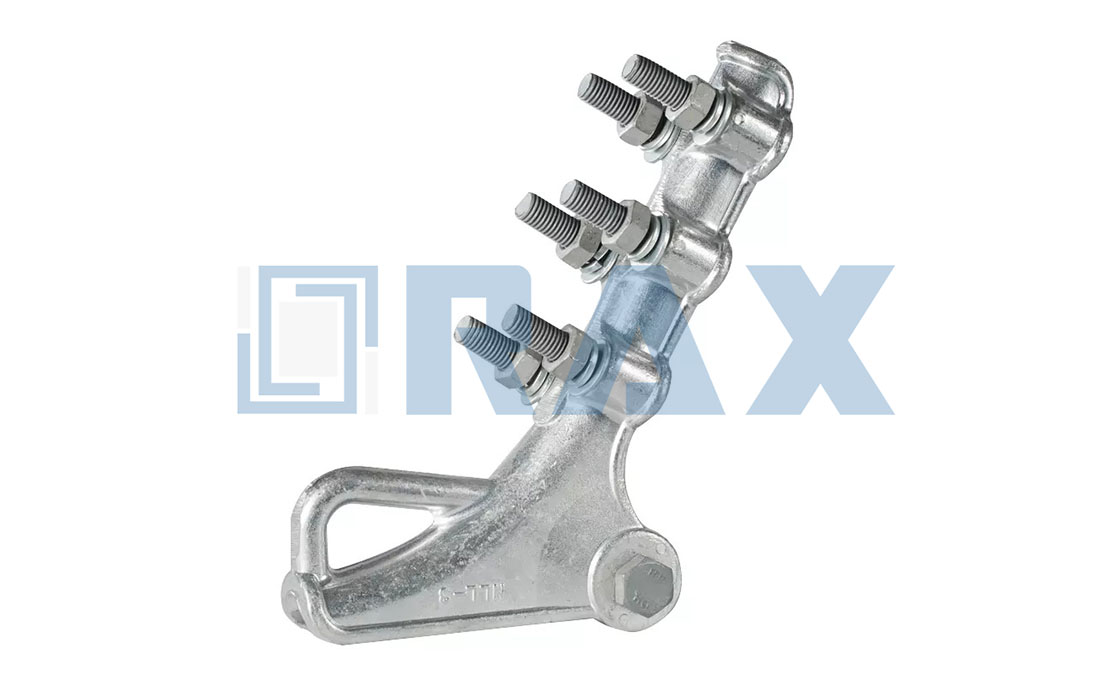

2. Tension Clamp

Tension Clamp

A tension clamp is an overhead fitting whose purpose is to terminate the conductor at different points.

It also provides electrical and mechanical connections to the insulator.

A tension clamp also serves as a protective fitting to the conductor.

3. Clevis Extension

As an overhead line accessory, a clevis extension is a U-shaped metal connector that other components of the overhead line fit into.

It has a head and a bolt that the conductor or even the insulator can pass through.

4. Anchor rods

Anchor Rod

Anchor Rod

Anchor rods are directly attached to the pole or towers of the overhead lines.

They are embedded in the foundation of these structures to offer support and stability.

Anchor rods have several components such as bolts, stiffeners, and plates.

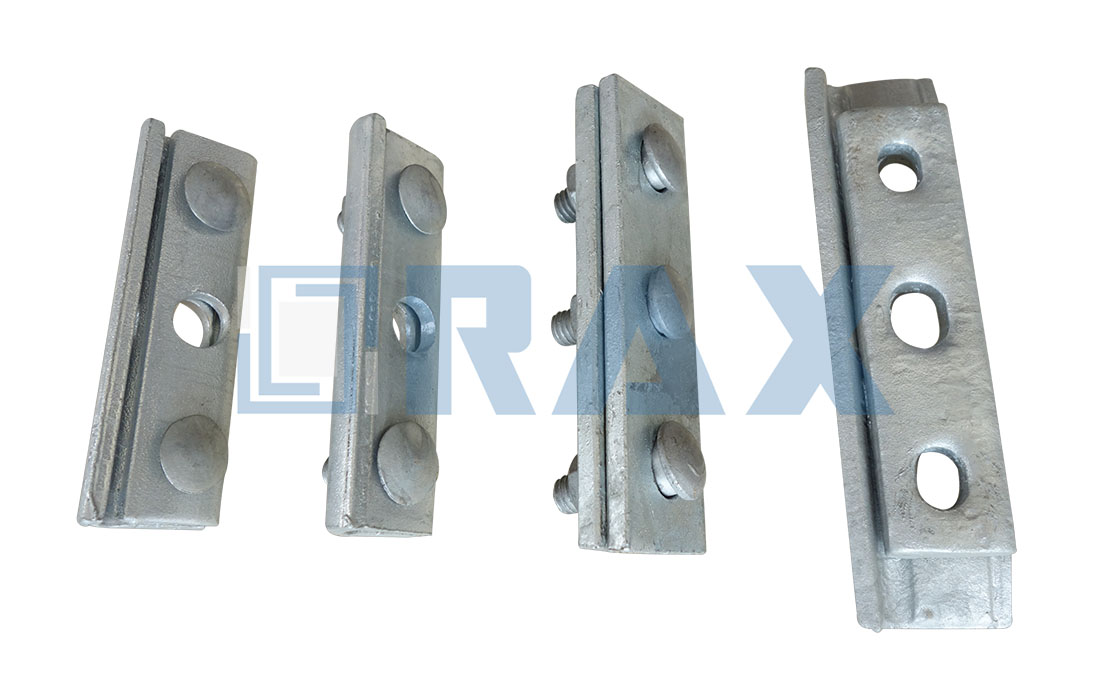

5.Mid span joints

The midspan joint is an accessory used for connecting two conductors that have different lengths.

Usually, they are connected in between the pylon towers to form tension joints.

6. Armor Rods

Armor Rod

Armor rods mainly play a protective role in overhead lines.

They are designed to protect the conductor from abrasion, bending, and compression.

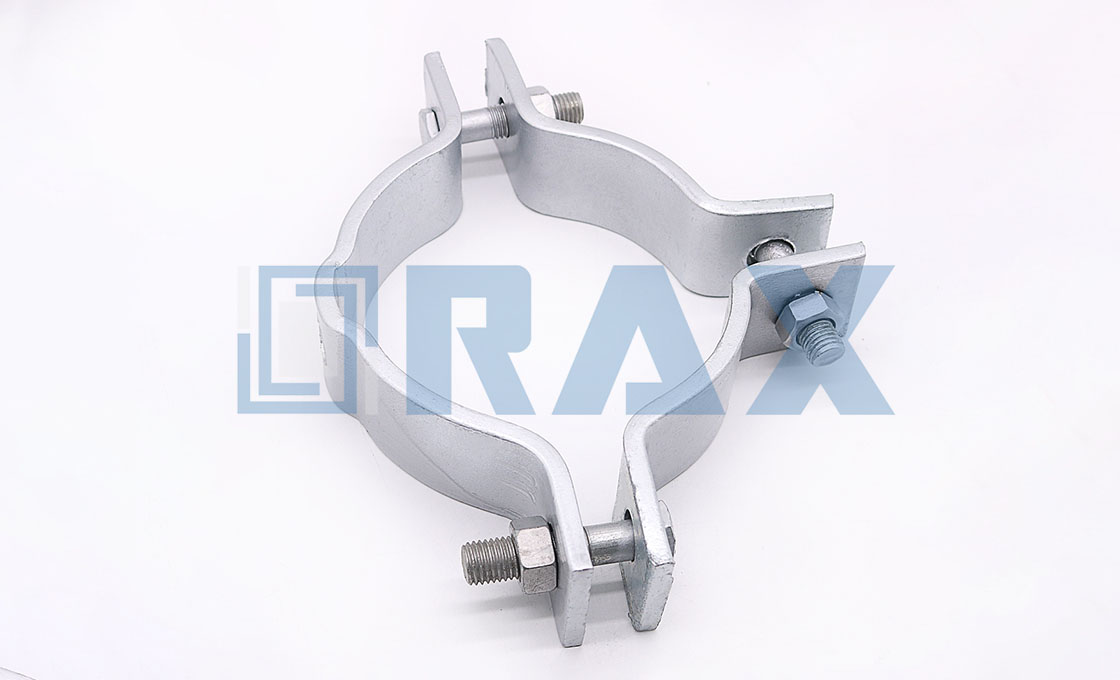

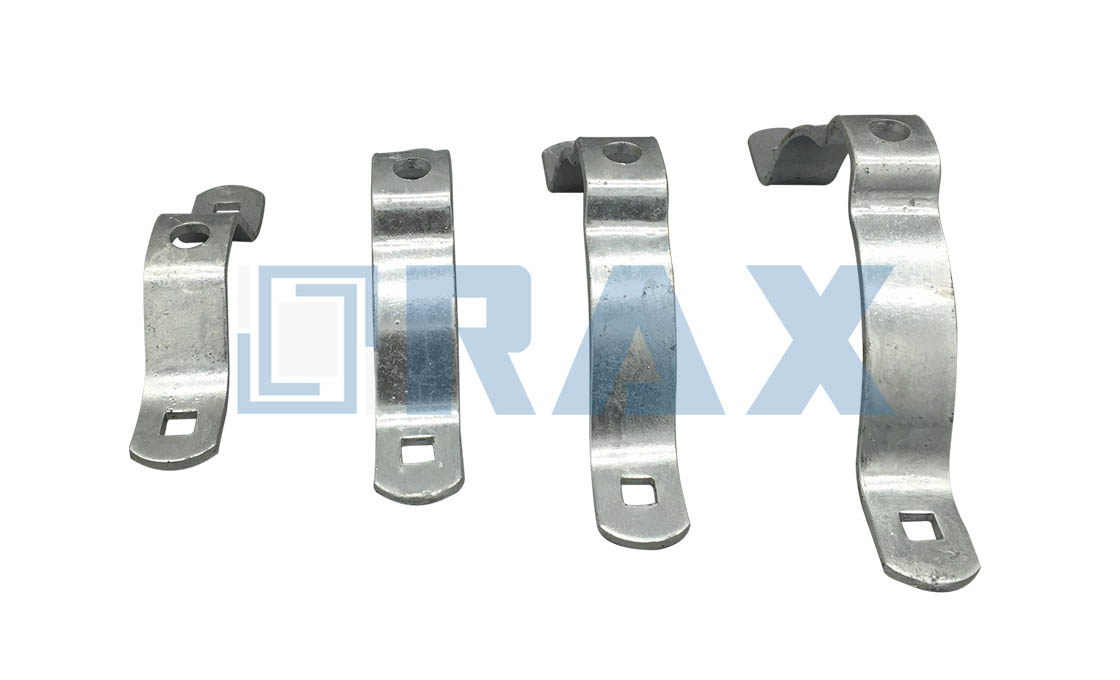

7. Pole Band

Pole Band

Pole Band

A Pole band is an accessory that holds other fittings into their perfect position.

It is a must-have accessory on any power line otherwise all your fittings will fall out of their position.

Since it plays a supporting role, a pole band needs to be strong and resistant to external elements.

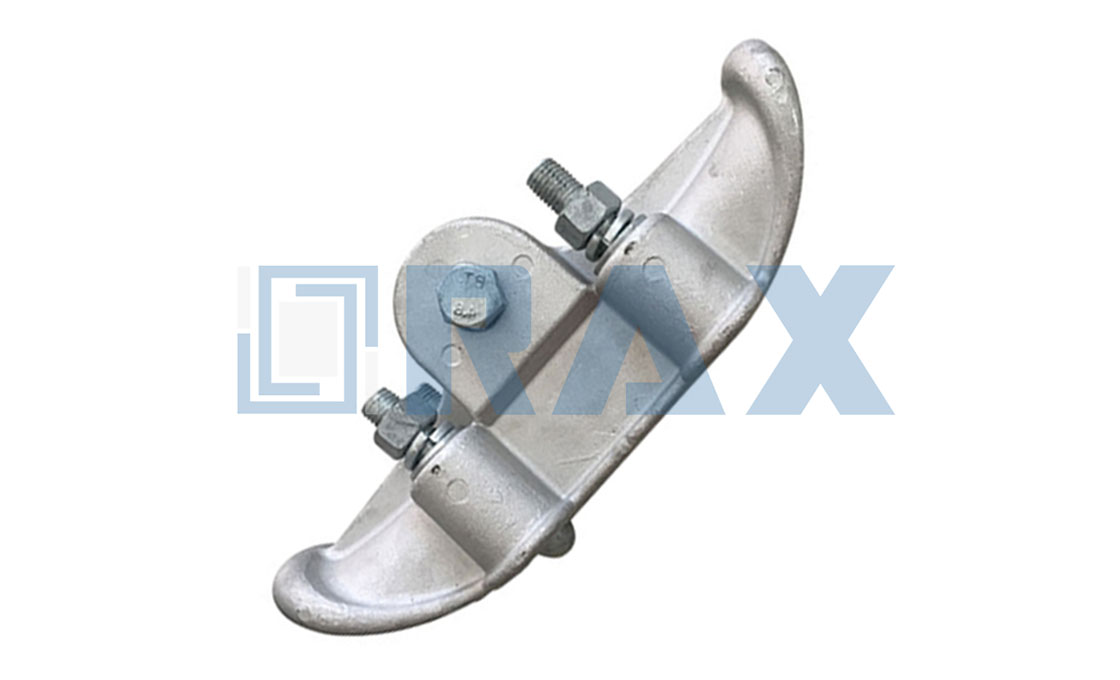

8. Dead End Clamp

This is another important fitting on an overhead line.

The main function of the dead-end clamp as overhead line hardware is to complete the connection of the overhead lines to the pole

This type of clamp comprises different components such as a piercing connector and is made of high-quality material.

Commonly used materials for dead-end clamps are steel and aluminum.

Choosing the Best Overhead Lines Fittings

Once you know the exact overhead line accessories that you need, the next step is to purchase them.

But, with several models and brands in the market, how do you choose the best accessory?

Obviously, you want something that will give you true value for your money.

Here are the best tips for choosing overhead lines fittings:

1. Overhead line materials

What material has been used to make the accessory?

Whether it is a suspension clamp or any other fitting, you need to pay attention to the material that has been used.

Choose overhead line fittings that are made of high-quality or premium materials.

It is advisable to choose an accessory that is made of stainless steel or aluminum.

Given that the accessory will be exposed to all vagaries of nature, it should be made of a material that will deal with all the external forces

This is important especially when we consider that some fittings are designed to protect the conductor.

Is the electrical overhead line material hard or tough enough to survive the harshest conditions?

Can it rust if exposed to water under other unfavorable conditions?

Check the specifications of the material as stated by the overhead line fittings manufacturer.

2. The design of the fitting

Take your time to carefully analyze the design of the accessory or fitting.

By design, we simply mean the physical appearance of the accessory.

In terms of the design, look at the measurements of the fitting.

Do they match the requirements of your powerline?

If it is a tension clamp, its dimension should perfectly match that of the conductor.

3. Cost of overhead line fittings

The price of overhead fittings is one factor that you cannot ignore.

It is important to know how much you will spend on the fittings.

This will knowledge will help you to properly plan for your budget.

Before making the purchase, spare some time to compare the prices offered by different overhead line fittings manufacturers.

By the rule of nature, you will be expected to buy the cheapest overhead line fittings.

However, you should not always rush to buy cheap products.

Instead, analyze the quality of the product.

An accessory can be cheap just because it is made of low-quality material.

As they always say, cheap will be expensive.

4. Overhead Lines Manufacturer

Do not just buy overhead power lines from anyone.

You should be careful with the manufacturer that you choose.

An overhead line hardware supplier can leave you with either a good or nasty experience.

Some can sell you quality fittings while others will sell you faulty fittings.

On the same note, some manufacturers charge reasonable prices while others will overcharge you.

So what should you do to end up with the best overhead line fittings manufacturers?

Just use the following checklist:

-The Experience of the Manufacturer: How long has the manufacturer been in the industry?

It is always advisable to buy from experienced manufacturers.

This is because they know all the dynamics that revolve around this industry.

-The capacity of the manufacturer: Does the manufacturer have the resources and technology to produce the best fittings?

One way of knowing this is by visiting their premises.

-Is the manufacturer licensed? Check if the manufacturer that you are dealing with is licensed to operate in China.

Licensed companies strive to meet strict regulations when selling to their customers.

Let them prove it to you by showing them their necessary documents.

-Referrals: People who have bought power lines fittings can refer you to the best manufacturers and suppliers.

-Online referrals: Online platforms such as social media can play a vital role in helping you to find reliable overhead line fittings suppliers in China.

Conclusion

There is no doubt that buying overhead line accessories can be a daunting task.

It requires you to take well-calculated steps.

But once you know the exact fittings that you should buy and find a reliable manufacturer, everything will fall into the right place.

Learn More:

FAQ

What is overhead line fitting?

Overhead line fitting is a wide range of steel fittings that are used to construct the overhead line, it is used to hang, connect or protect conductors or insulators.

Overhead line fitting is also called overhead line hardware or overhead line accessories.

What are the types of overhead line fittings?

According to the function, overhead line fittings can be divided into:

- String hardware

- Suspension clamp

- Tension clamp

- Splicing fitting

- Protective fitting

- Dead end fitting

What is the key consideration when choosing overhead line fittings?

- Overhead line materials

- The design of the fitting

- Mechanical Properties of the Overhead Line Fittings

- Electrical Properties of Overhead Line Fittings

- Cost of overhead line fittings

- Overhead Lines Manufacturer