All over the world, professional companies generally use guy wires as a supporting element to stabilize structures in the antenna, communications, and utility projects.

guy wires attached to broadcast antennas

Why is the guy wire so important? And how is it used? If you do not have a clear understanding, do not worry, In this complete guide, We’re going to dig deep into ‘guy wire‘, you can jump to any section that interests you:

Table of Contents

- 1 Guy wire definition: What is a guy wire?

- 2 Why is it called “guy wire”?

- 3 How is a guy wire used?

- 4 What is the application of a guy wire?

- 5 Guy Wire Fittings

- 6 When do you need guy wires?

- 7 How to install a guy wire?

- 8 Inspections and tests on guy wires

- 9 The features of a good guy wire

- 10 Specification guide to buying guy wires

- 11 How to choose the best guy wire manufacturer?

Guy wire definition: What is a guy wire?

Galvanized Guy Wire

A guy wire is a tensioned cable, wire, or rope that is used to brace, guide or secure all sorts of structures like ship masts, electric poles, radio towers, or wind turbines, which are of considerable heights and not self-supporting in place.

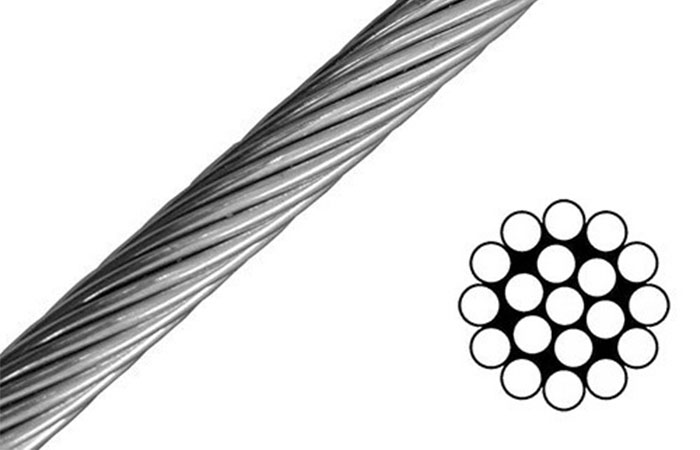

The cables bear a high tension, so for industrial purposes, the cable consists of wires of galvanized steel, which makes the guy wires extremely strong.

Why is it called “guy wire”?

The guy derives from a Dutch word, gei, which was a rope used to fix a furled sail to a mast. When it came to any line used to keep something stable, it was also named strand wire, stay wire, guy strand, guy cable, guy anchors, sometimes mistakenly called ”guide wire” (The word guide is of French origin which has nothing to do with guy wire).

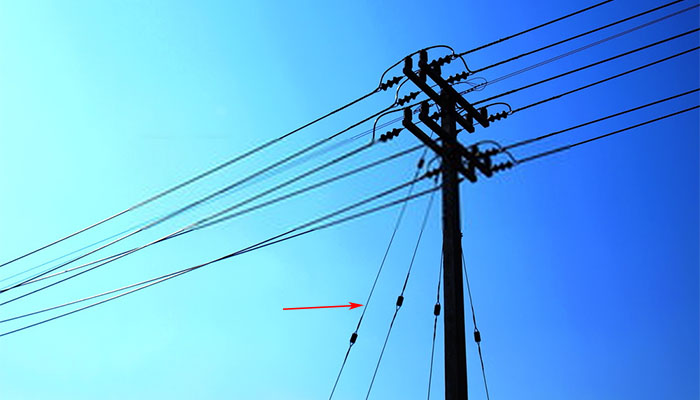

Guy (red arrow), controlling the spinnaker pole

Guy (red arrow), controlling the spinnaker pole

How is a guy wire used?

A guy wire is designed to transfer some of the weight of the structures to the ground. It is used to support kinds of electric poles and towers in the power system, or hold up aerial masts for broadcasting and communications.

guy wire attached to the top of the power pole

guy wire attached to the top of the power pole

One side of a guy wire is connected to a point high up on the structure, and the other hand is anchored to a safe point on the solid ground, creating a diagonal line. An anchor concreted into the solid ground can is used to hold one or more guy wires steady.

guy wire attached on the ground

guy wire attached on the ground

What is the application of a guy wire?

For Power system

Utility Lines run for longer distances with many utility poles or towers, and they need to cross many places. Because of the enormous tension stress of utility lines between the poles or towers, on the opposite side, guy wires are connected from the pole to the ground to support the unbalanced lateral loads, make sure the structures be straight and prevent the ground from moving.

Utility pole guy wire

Utility pole guy wire

Note: A guy wire is usually used with a guy set, which is insulated to avoid electric shock if any person touches it.

For telecommunications and broadcasting

Guy wires used to support the telephone pole or antenna mast are about the same as they are for the power system.

guy wires for telecommunications and broadcasting

guy wires for telecommunications and broadcasting

Be clear that NEVER install a mast near AC power lines.

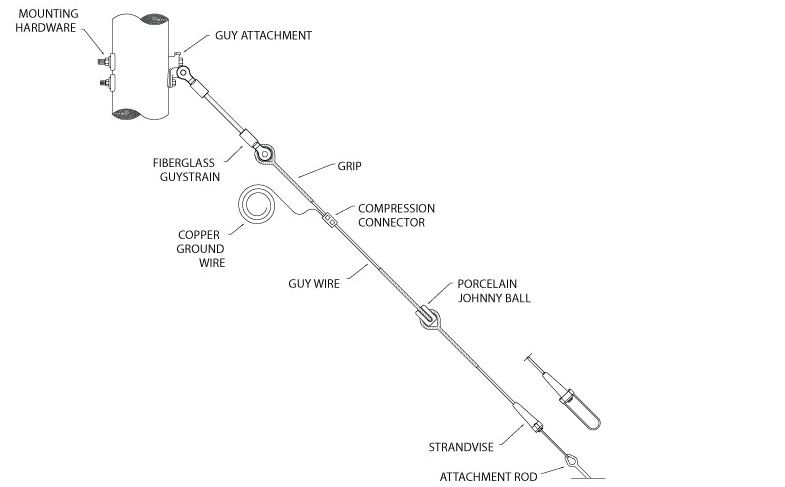

Guy Wire Fittings

Guy wire is designed to use with several fittings and components for different applications, and they are used together to provide stability to towers, antennas, and other utility structures.

Dead End Grip

According to the program, the dead end grip comprises guy wire dead end grips, preformed dead end grip used on the conductor, and preformed grip. Guy wire preforms are used on end poles. The guy wire preforms join the anchor rod or insulator to achieve the use of setting the pole.

Guy Grip

The guy grip has formed legs using grits on each turn that retains the messenger conductor wire or fiber optic cable securely.

The guy grip is also known as the guy grip end or preformed guy grip, it’s used to link and traction grounding cable, the conductor, and the optical fiber program.

The strand is tacked with all the bent area of the guy grip.

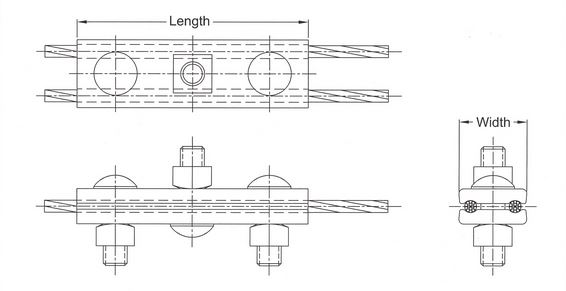

Guy Clamp

A guy clamp is used on the communication line. It is used along with the stay wire and anchor rod to generate the pole securely.

After the stay wire goes around the anchor rod, the 3 bolt clamp bites the close of the stay wire to protect against the stay wire from slipping down. The grooves of this guy clamp the stay wire, and the bolt will secure two pieces of guy clamp clamping the stay wire.

Guy Thimble

Guy thimble is also called cable thimble, and it is accessible on the electric power line or dead-end pole line. The cable thimble connects using all the preformed tension clamps to help and safeguard the ADSS/OPGW cable.

According to the sizes of these strands, there are forms for you.

Pole Band

The Pole band is also a fitting utilized together with the guy wire. According to the arrangement, the pole band incorporates a single offset pole band and a double offset pole band. According to the program, you will find utility pole bands, telephone pole brackets, and cable pole bands.

Pole Top Make Off

Pole top makes off is used as a clamp on the top of the power pole, it replaces the wedge clamp and firms the pole on the earth.

Shackles

Used for connecting wire rope, chain, and slings.

Stay insulator(or egg insulator)

An insulator at a stay wire or guy wire is under pressure if it’s connected at both ends. Substances have higher compressive strength than strength because the pressure is acting to pull on the substance while forces are tending to push it.

Insulators for use in stay wire are made so that strain on the cord is converted into a force, as shown in the picture of a stay insulator made from porcelain, glass, or ceramic.

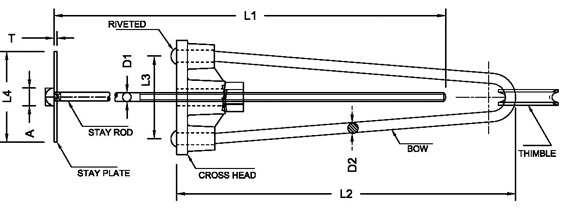

Stay rods

From falling under stress, the stay rods supported the joined part, and they’re utilized with guy wires in tower construction and electricity poles.

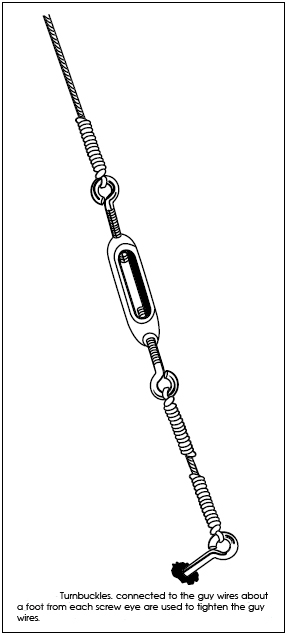

Turnbuckles

Used to pull together or push apart guy anchors.

When do you need guy wires?

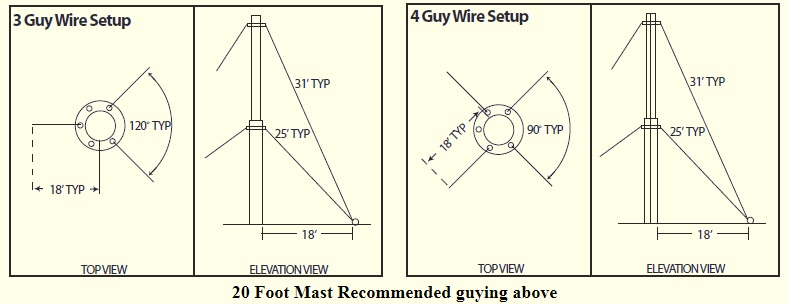

The taller the structures are, the more substantial and more Transverse distance due to the wind force. Almost all the towers and masts more than 20 feet have guy wires supporting them. The height may be decreased to 10 feet when the tower or mast is set in areas of steep terrain or with frequent severe weather.

In this case, the guy wires should be installed appropriately to secure and protect them from breaking.

If you’re going to work on a project, you’d better consult the local city planning officer who is in charge of the construction standards first. Because the rules are not the same in different markets, countries, or cities, you should always obey the local standards and requirements of the party.

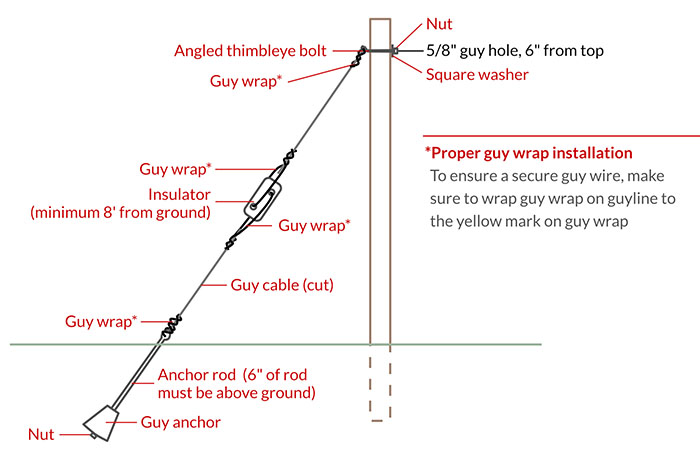

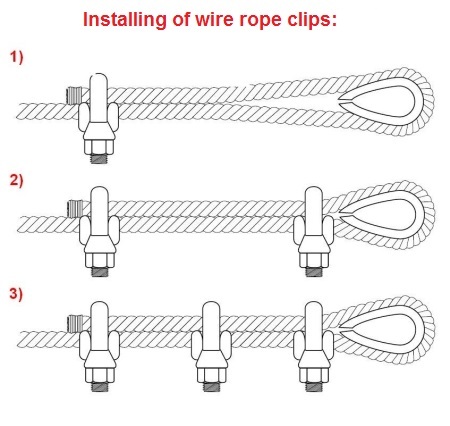

How to install a guy wire?

Even though the installation is easy, the guy wire should not be installed do-it-yourself, experienced professionals should only do it. You should prepare the guy wire and fittings, such as guy grip, guy clamp, or guy thimble before the installation.

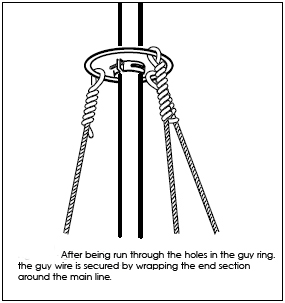

First: Connect one side of three or four guy wires to the top of the structure. They can be twisted on or attached to the mounting bolts.

Then: Attach the other side of the guy wires to points on the ground, and tight the cables so that all of them can’t move. Ideally, the three wires should be mounted 120 degrees(If four wires then 90 degrees) and as far as possible apart from each other.

Inspections and tests on guy wires

Since the guy wire is utilized for electrical functions, security is mere that the hardware needs to tackle, it should guarantee the security levels.

Lubrication inspection when manufacturing: The manufacturer should inspect with equipment the cable and lubricate the cable with specialized equipment, both the core and the outer perimeter.

Tension inspection before delivery: In the factory, The expert should handle proper equipment to do the workload capability test. The current condition and strength of the cable should be considered.

Tension breaking strength examination before installation: The engineer should examine strands regularly to ensure that the wires comply with the tension breaking strength limits.

Rope periodical inspection after use. The following aspects should be inspected:

- Excessive broken wire

- Distortion or kinking

- Severe corrosion

- A one-third Decrease in the outer wire diameter

- Damaged or displaced clamp, thimble, anchor, or other end components

The features of a good guy wire

Excellent guy wire means it can safely support structures for a long time. It has the function below:

- Lightweight, selection of quality raw materials

- Good design, add hardware quickly and securely.

- A little stretch. Little damage to the finish, which can protect the structure over time.

- High break strengths can withstand great tension

- Durable, Longer service life.

Specification guide to buying guy wires

The guy wire is of high strength grade based on ASTM A475 Standard Specification for Zinc-Coated Steel Wire Strand”.

One critical thing that you need to know when choosing guy wires can be divided into several aspects:

Material

The base metal is steel produced by the open-heart, basic oxygen, or electric furnace procedure. It is of quality and purity that if attracted to the dimensions and coated with zinc, the strand and also wires will probably be of uniform quality and possess the properties and attributes as prescribed in ASTM A475.

Stranding

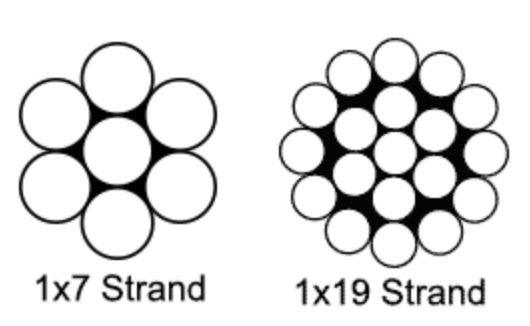

The wire strands covered in this specification are commercially known to be all kinds of seven-wire (7-wire) or nineteen-wire (19-wire) strands.

Tension and Design

Determine the minimum steel gage, number of guys, etc.

Guy wires should be designed according to the standards(such as ASCE 7

-95: Minimum Design Loads for Buildings and Other Structures) and

client design requirements (height, diameter, wind speed, gust, shape

and terrain factors).

| Size | Strand | Weight Lbs./Ft. | Breaking Strength | Initial Tension |

| 3/16″ | 1×7 | 0.08 | 5,000 lbs. | 500 lbs. |

| 1/4″ | 1×7 | 0.117 | 6,650 lbs. | 665 lbs. |

| 5/16″ | 1×7 | 0.171 | 11,200 lbs. | 1,120 lbs. |

| 3/8″ | 1×7 | 0.22 | 15,400 lbs. | 1,540 lbs. |

| 7/16″ | 1×7 | 0.399 | 20,800 lbs. | 2,080 lbs. |

| 1/2″ | 1×7 | 0.517 | 26,400 lbs. | 2,640 lbs. |

| 9/16″ | 1×7 | 0.67 | 35,000 lbs. | 3,500 lbs. |

| 5/8″ | 1×19 | 0.813 | 42,400 lbs. | 4,240 lbs. |

| 3/4″ | 1×19 | 1.155 | 58,300 lbs. | 5,830 lbs. |

| 7/8″ | 1×19 | 1.581 | 79,700 lbs. | 7,970 lbs. |

| 1″ | 1×19 | 2.073 | 104,500 lbs. | 10,450 lbs. |

guy wire tension chart

Weight of Coating

The weight of zinc coating is determined by the stripping Evaluation Based on ASTM Test Method A90″Test Method for Weight of Coating on Zinc-coated (Galvanized) Iron or Steel Articles.”

Adherence of Coating

The slab zinc where the coat is derived is going to be some level of zinc conforming to ASTM B6″ Specification for Zinc (Slab Zinc).”

Finish

The zinc-coated wire is free of imperfections not consistent with good commercial practice. The zinc coating is constant and of reasonably uniform thickness.

You can see the detailed specification here.

How to choose the best guy wire manufacturer?

Quality suppliers with high technology and production capacity, so you can put less energy into the products. Here are the guidelines that can help you to end up with a suitable manufacturer:

- Check whether the company is licensed

- The production capacity of the company

- Look for the reviews about the manufacturer

- Experience of the manufacturer

- Up to Regional quality standards

As a reliable guy wire manufacturer and supplier in China, RAX Industry can supply you with a series of guy wires. Custom sizing and pricing are also available. If you have any questions, contact us now.

A guy wire is a tensioned cable, wire, or rope that is used to brace, guide or secure all sorts of structures like ship masts, electric poles, radio towers, or wind turbines, which are of tremendous heights and not self-supporting in place.

The cables bear a high tension, so for industrial purposes, the cable consists of wires of galvanized steel, which makes the guy wires extremely strong.

The guy apparently derives from a Dutch word, gei, which was a rope used to fix a furled sail to a mast. When it came to be used of any rope used to keep something Stable, It was also named strand wire, stay wire, guy strand, guy cable, guy anchors, sometimes mistakenly called ”guide wire” (The word guide is of French origin which has nothing to do with guy wire).

A guy wire is designed to transfer some of the weight of the structures to the ground. It is used to support kinds of electric poles and towers in the power system, or hold up aerial masts for broadcasting and communications.

One side of a guy wire is connected to a point high up on the structure, and the other hand is anchored to a safe point on the solid ground, creating a diagonal line.

An anchor concreted into the solid ground is used to hold one or more guy wires steady.

The taller the structures are, the more substantial and transverse distance due to the wind force. Almost all the towers and masts more than 20 feet have guy wires supporting them. The height may be decreased to 10 feet when the tower or mast is set in areas of steep terrain or with frequent severe weather.

In this case, the guy wires should be properly installed to secure and protect them from breaking.

If you’re going to work on a project, You’d better consult the local city planning officer who is in charge of the Construction standards first. Because the rules are not the same in different markets, countries, or cities, you should always obey the local standards and requirements of the party.

Different components are used with guy wires for various applications:

Dead End Grip

Guy Grip

Guy Clamp

Guy Thimble

Shackles

and so on.

You can see more components here.

Here is the guideline that can help you to end up with a suitable manufacturer:

Check whether the company is licensed

The production capacity of the company

Look for the reviews about the manufacturer

Experience of the manufacturer

Up to Regional quality standards