In 2016, We worked with a customer who is from Tunisia.

The first time we worked with them was in 2011, They achieved the tender from the local government, and ordered the socket clevises and ball eyes from us.

It’s a two containers’ order.

That order went smoothly and no any trouble.

At Sep. 2016, the customer achieved the socket clevis and ball eye tender again.

We do this order according to the same experience that we have done in 2011.

When the goods almost finished and we invite the customer to come to inspect the ball eye and socket clevis goods, the customer notices us they will do the gauges test according to IEC120.

The IEC standard applies to string insulator units of the cap and pin and long rod types and their associated metal fitting.

The object of this standard is to define the dimensions of a series of standard ball and socket couplings using the standard locking devices in order to permit the assembly of insulators or metal fittings supplied by different manufacturers.

Indeed, we know the IEC 120 test standard, but not all customers need to do this test.

Because the customer didn’t inform us of this test at the beginning, so our goods were not so accurate.

Then our workers do some treatment on the finished socket clevis and ball eye.

Are you more patient than our workers?

They select the goods not less than 3 times to promise to pass the test 100%, It’s not 1000pcs, not 10000pcs, it’s 160000pcs.

With no doubt, we passed the strict inspection finally.

Now let’s review how the customer test the ball eye by gauges:

- The customer selected 30 pcs sample from the 34pallete

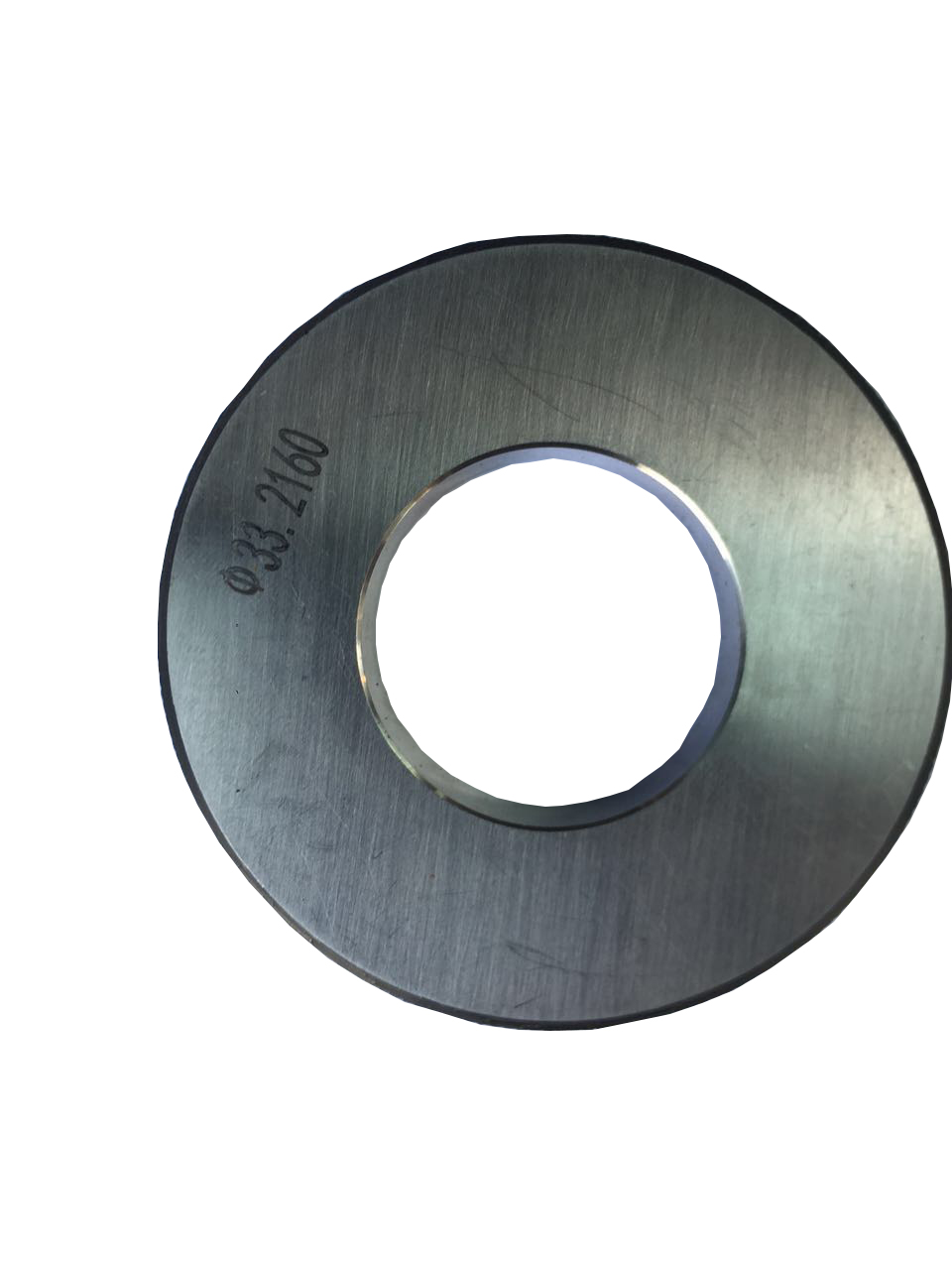

2. Test by “GO” gauges and “NOT GO” gauges

“GO” gauges

a

b

c

d

e

The way to use the gauges is as below:

a) Ball and shank shall pass in at least one direction through “GO” gauges for ball height, shank diameter, and shank length

b) Ball shall pass through “GO” gauge for all diameter

c) Ball and shank shall not pass in any direction through “NOT GO” gauge for ball height

d) Ball shall not pass in any direction through “NOT GO” for ball diameter

e) Shank shall not enter in any direction through “NOT GO” gauge for shank diameter

Are you more strict than our present customer, If yes, we are pleasure to accept any new challenge!

Please not hesitate to send us an inquiry.