It ’s an experience to work with a very kind customer who is from South America.

That’s the first time to work with him.

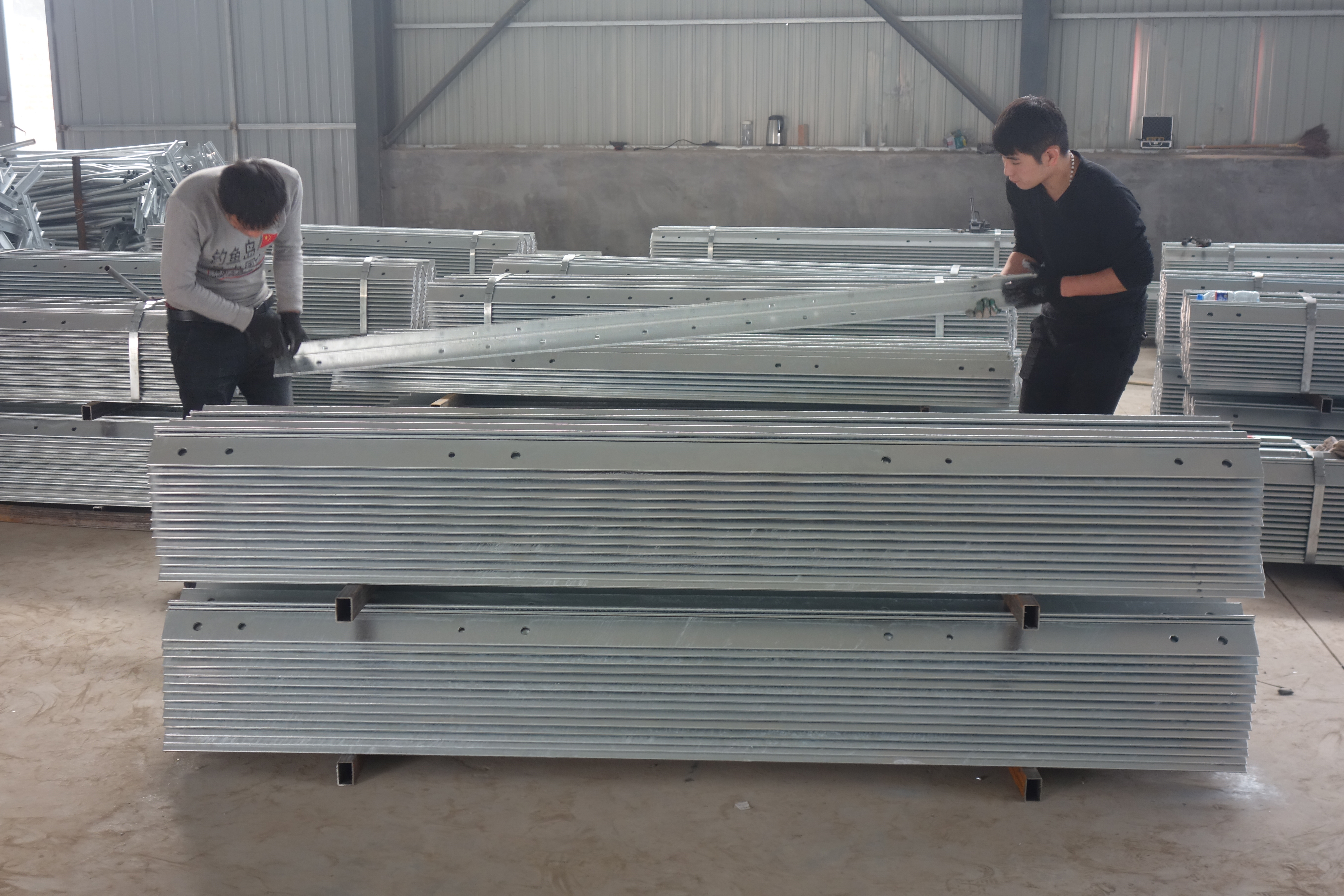

The customer ordered pole band, D bracket, Street Light Arm and electrical cross arm.

We know the inspection standard of the South America market.

And we make the electrical cross arm very carefully.

We confirm each detail with the customer.

All the sizes are in +5%.

And the raw material carbon steel is first-class quality.

The electrical cross arm raw materials are new with no welded or jointed section.

Because the customer is very busy, he didn’t come to inspect the goods before we send.

While Jingyong workers and QC inspector check the electrical cross arm very strictly.

They select twice and grind the flux residues.

45days later, when the customer got the goods, He is very happy with the surface treatment.

It seems everything going well.

While an unexpected thing happened.

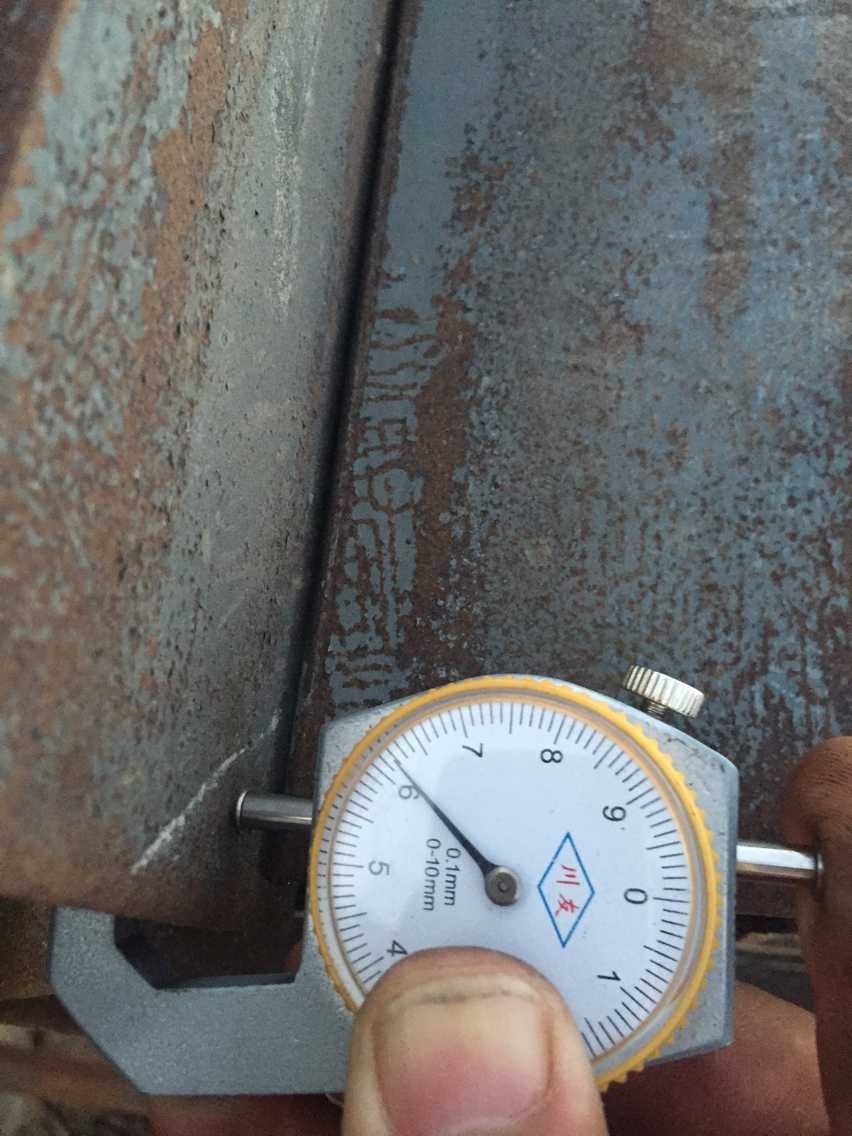

Their company inspector checked our steel cross arm galvanized thickness is less than the ISO1461 required.

Now Let me add some information about the ISO 1461 TEST

Article and its thickness | Local coating thickness μm | Local coating mass g/m2 | Mean coating thickness μm | Mean coating mass g/m2 |

| Steel> 6mm | 70 | 505 | 85 | 610 |

| Steel>3mm to<6mm | 55 | 395 | 70 | 505 |

| Steel>1.5mm to<3mm | 45 | 325 | 55 | 395 |

| Steel <1.5mm | 35 | 250 | 45 | 325 |

| Castings>6mm | 70 | 505 | 80 | 575 |

| Castings<6mm | 60 | 430 | 70 | 505 |

We know there must be some mistake on it.

When we send our own galvanized thickness device to go to that customer by DHL.

And ask that customer to test it again.

They found it’s no problem with the galvanized thickness.

It’s the customers’ test device needed to be calibrated.

The customer is very pleased with the result.

From then on, the customer increased the purchasing quantity from us.

It’s a real story between Jingyong and the customer.

We hope you will be our next customer.