Forged Eye Bolts

Forged eye bolt is a type of fastener widely used on the wooden pole to support thimbles, clevises, links, and dead end insulators in electric power lines or overhead lines. It is also called a drop forged eye bolt. The eye bolt is assembled with one or more square nuts, which fasten the eye bolt when going across the wooden pole. Forged Eye Bolts include oval eye bolts and round eye bolts.

The oval eye bolt is designed with an over thimble head which is a locked circle when connected with the clevis or dead-end insulator. It does not drop off easily. There are two designs of oval eye bolts: regular oval eyebolts and double arming eyebolts.

A shoulder eyebolt is the same as the main function of an oval eye bolt. Shoulder Eyebolt is a type of round eye bolt that is designed with an integral shoulder, which provides a greater bearing surface to reduce stress on a utility pole or electrical cross arm.

The eye bolt is hot drop forged. The drop forged eye bolt does not have any welded point. The forged eyebolt is more resistant to breaking load than the welded eye bolt.

Compared with other forged eye bolt manufacturers, Rax Industry knows how to control the good quality and improve efficiency. Experienced engineers, control the process line and all workers pay attention to every detail. We have successfully made many types of custom forged eye bolts.

If you have any new designs, never hesitate to contact us.

Rax Industry forged steel eye bolt has a breaking load of 50kn for 5/8’’ and 55kn for 3/4’’.

The diameter of the eye bolt includes 3/4’’ and 5/8’’. The thread length as per the drawing.

The surface treatment for the eye bolt is hot dip galvanized. The galvanized steel eye bolts have no zinc block on the screw.

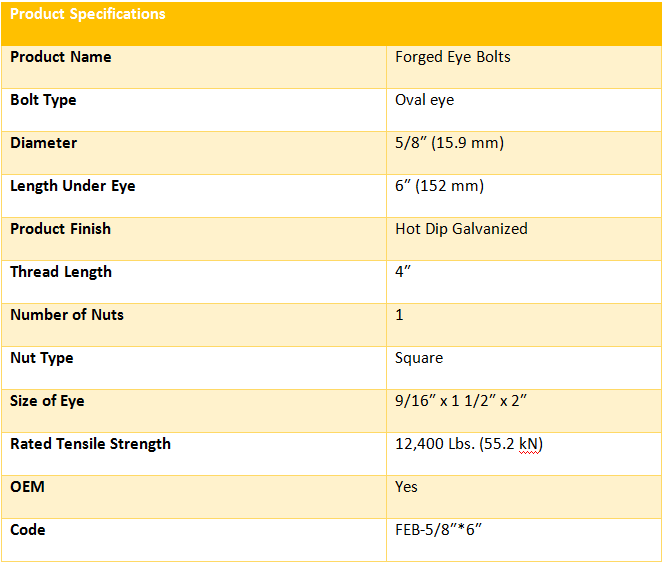

| Product Specifications | |

| Product Name | Forged Eye Bolts |

| Bolt Type | Oval eye |

| Diameter | 5/8″ (15.9 mm) |

| Length Under Eye | 6″ (152 mm) |

| Product Finish | Hot Dip Galvanized |

| Thread Length | 4″ |

| Number of Nuts | 1 |

| Nut Type | Square |

| Size of Eye | 9/16″ x 1 1/2″ x 2″ |

| Rated Tensile Strength | 12,400 Lbs. (55.2 kN) |

| OEM | Yes |

| Code | FEB-5/8″*6″ |

Q1: Do you have stock for forged eye bolt 3/4?

A: Yes, we have stock for both forged eye bolt 3/4 and 5/8.

Q2: Do you have Forged Eye Bolts size chart?

A: Yes, pls contact [email protected] to get it.

Q3: What’s your drop forged specification?

A: Pls check Rax Industry forged eye bolt specification here.

Forged Eye Bolts: An Ultimate Guide for Importers

Today, I want to introduce you to yet another important pole line hardware – forged eye bolts.

Whether you want to connect a dead-end insulator or overhead line, you need high-quality forged eye bolts.

And, that’s exactly what you will learn here – from technical specification, classification, material type, manufacturing process, installation procedure, etc.

By the end of this guide, you’ll be an expert in forged eye bolts.

- Chapter 1: What is an Eye Bolt?

- Chapter 2: Types of Eye Bolts

- Chapter 3: Eye Bolt Materials

- Chapter 4: Main Components of Forged Eye Bolts

- Chapter 5: Technical Specifications of Forged Eye Bolts

- Chapter 6: Application of Forged Eye Bolt

- Chapter 7: Why customers trust Rax Industry galvanized forged eye bolt

- Chapter 8: Forged Eye Bolts Manufacturing Process

- Chapter 9: Step-by-step Forged Eye Bolt Installation Process

- Chapter 10: Frequently Asked Questions (FAQs)

- Chapter 11: Conclusion

What is an Eye Bolt?

An eye bolt is among the commonly utilized pieces of equipment in handling of material.

Eye bolt is made of a simple design, comprising of a threaded shank with an eye or ring at one end.

The design of an eye bolt enables passing of a cable or rope through the loop hence facilitating lifting of objects.

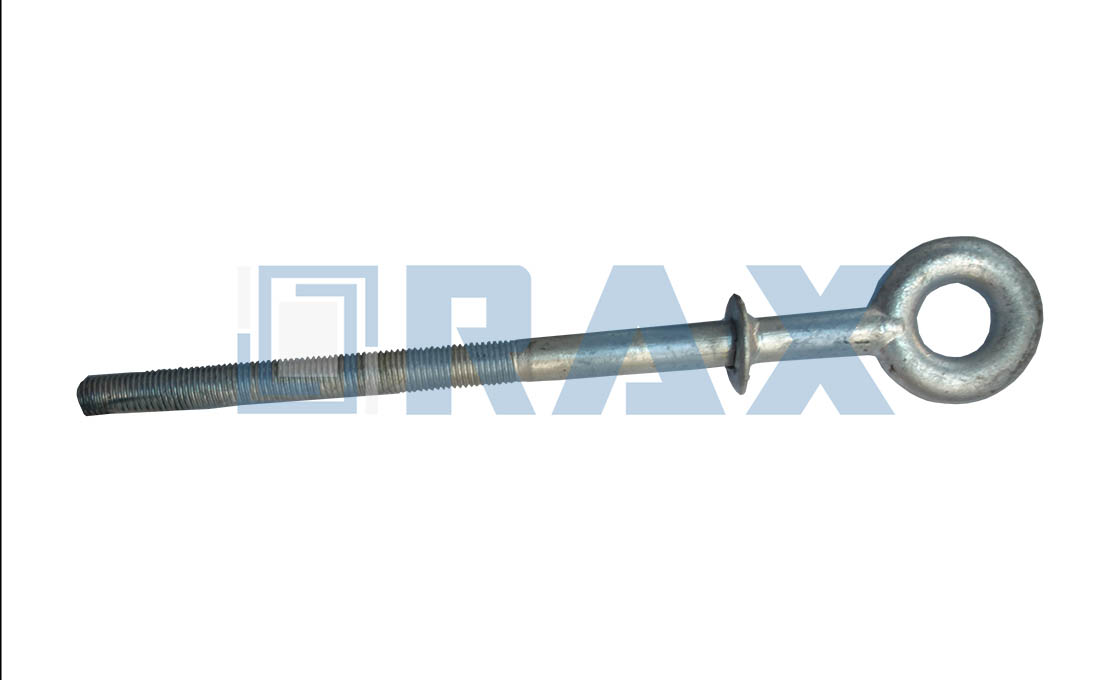

Forged eye bolt

Forged eye bolt

Typically, the installation of eye bolts is on materials such as steel or wood poles, and you use nuts to fasten them.

You can form the eye by either bending the steel to form a loop or through hot-drop forging.

You should use bent eye bolts for light-duty applications only.

Moreover, a bent eye bolt is not suitable for angular lifting.

Types of Eye Bolts

There exist four functional kinds of eye bolts.

- Forged eye bolts are forged instead of being formed. These one-piece fasteners provide higher load ratings.

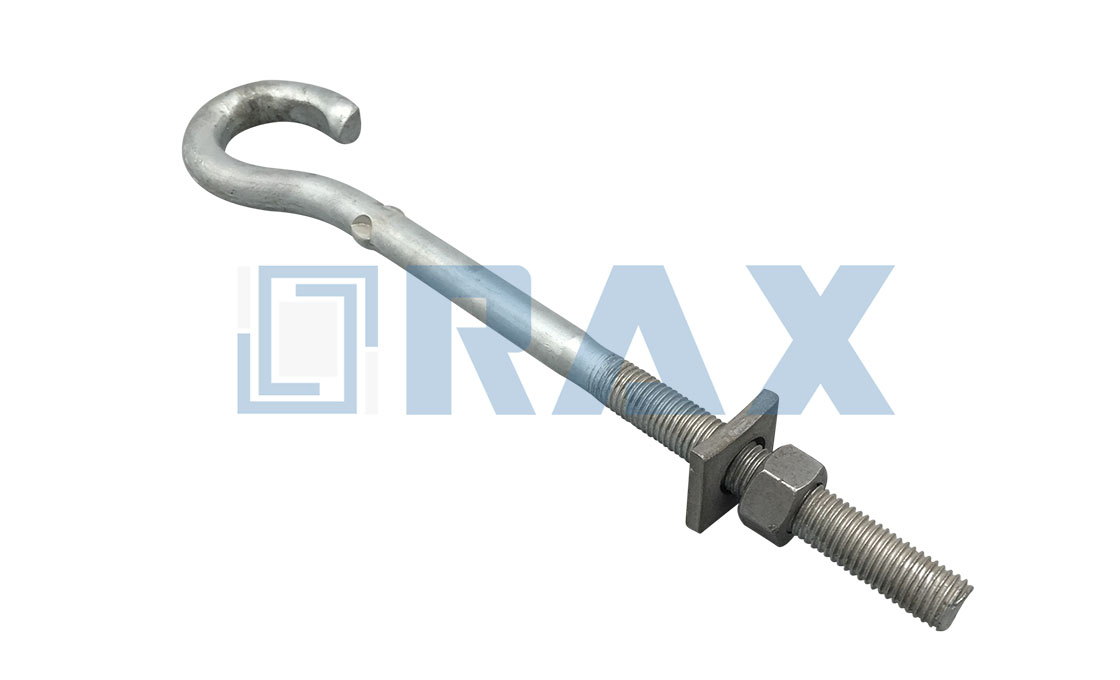

- Screw eyes are screws having a head molded into an eye or loop. Their usual use is for lifting and rigging, or for guiding cable or wire.

- Shoulder eye bolts consist of a shoulder below the eye. Often, you install the shoulder eye bolt flush with the mounting material.

- Thimble eye bolts have an opening that functions as a thimble for rope or wire to reduce wear.

- Pivoting eye bolts are designed to spin 180°. The bottom of a swiveling eye bolt is devised to swivel 360°.

Eye bolts

Eye bolts

Eye Bolt Materials

The most popular materials used for the manufacture of forged eye bolts are carbon, alloy and stainless steel.

Stainless steel drop forged eye bolts are generally rust-proof.

It is because the steel ingredients consist of chromium, silicon, molybdenum, iron, nickel, and very minimal quantities of carbon.

Due to this fact, stainless steel forged eye bolts will be more durable in marine applications.

Furthermore, the smooth look makes this kind of forged eye bolt fit for architectural uses, and a common option in food processing and pharmaceutical industries.

Normally, this is because of the absence of flaking and peeling.

Alloy steel drop forged eye bolts are suitable for cold weather uses.

Lifting works happening in temperatures below -1°C ought to be done utilizing an alloy steel forged eye bolt.

The metallurgical features of the alloy steel enable the preservation of the structural performance and integrity even in cold set ups.

You form galvanized steel forged eye bolts by lowering ordinary carbon steel into molten zinc.

The process of doing the dipping is known as hot dipping, which leads to an extra coat that shields against corrosion.

Due to this fact, galvanized drop forged eye bolts are suitable for outdoor uses since they are additionally resistant to the elements.

But, the finish of this forged eye bolt type is rugged and can experience peeling or flaking thus, for a superior finish, select stainless steel forged eye bolts.

Main Components of Forged Eye Bolts

Forged eye bolts have the following main parts and components:

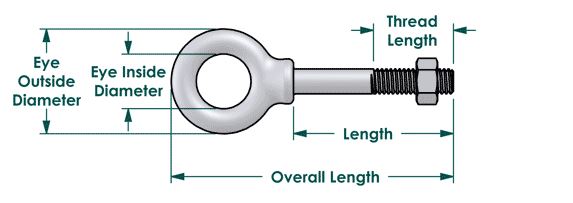

Parts of forged eye bolt – Photo courtesy: Bolt Depot

- Threaded steel bolt with a loop or eye at one end

- Nut

- Washer

Technical Specifications of Rax Industry Forged Eye Bolts

Specifications for eye bolts include:

- Maximum load capacity – The greatest load which a forged eye bolt can manage.

- Shank length – For completely-threaded eye bolts, the shank diameter is equivalent to the thread length.

- Threaded length

- Eye inside diameter (ID)

- Total weight

- Eye thickness or eye section diameter

Forged eye bolt

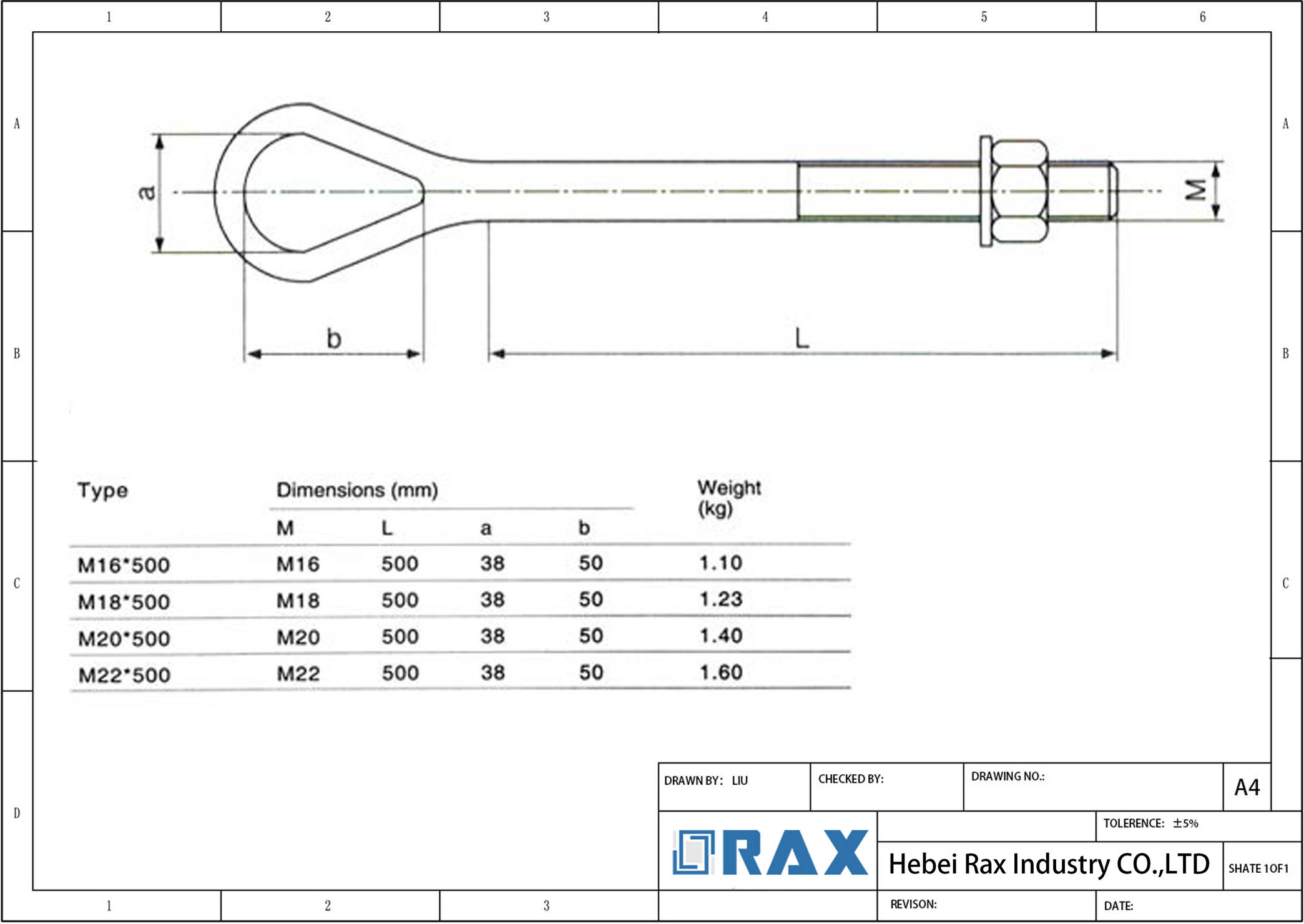

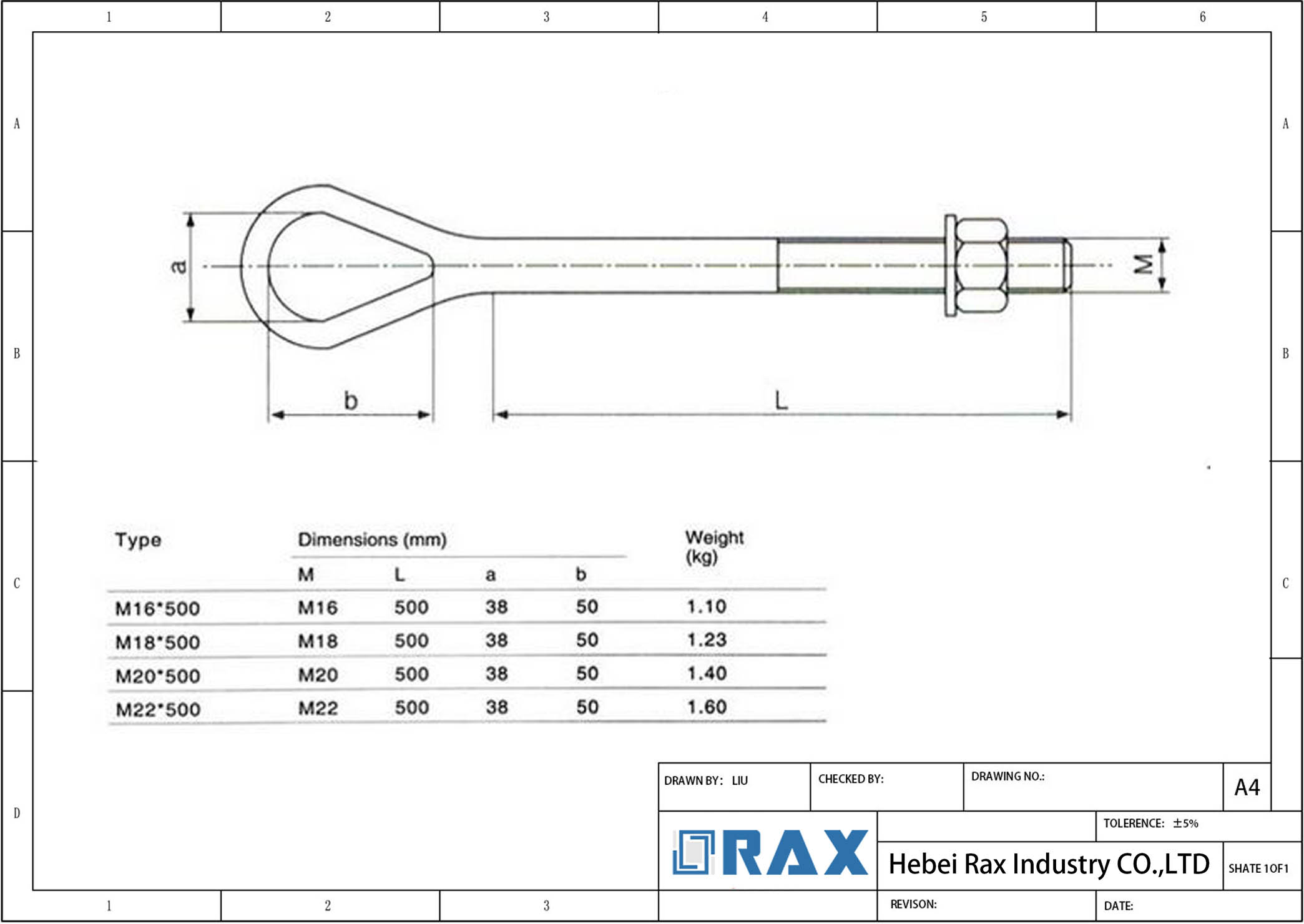

The table below shows our forged eye bolt specifications

Application of Forged Eye Bolt

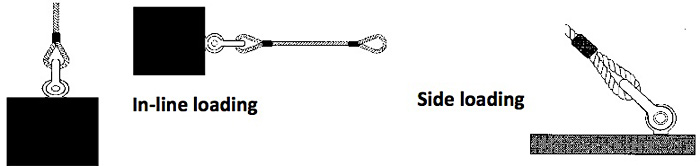

The typical use of forged eye bolts is to connect cables to items to facilitate lifting.

Oval eye bolt is suitable for connecting the dead-end insulator to the wooden posts in overhead or electric power lines.

You should use eye bolts produced by bending a wire or rod into a loop for light duty application only, since heavy loads may result in the opening of the eye.

Forged eye bolt application – Photo courtesy: Industrial Slicing and Sling

Welded or drop forged eye bolts are the best option for heavy loads because they can sustain loads equal to the tensile strength of the material used to make them.

Why do customers trust Rax Industry galvanized forged eye bolts?

- Rax Industry controls the forged eye bolts detail very well:

- At each end of the threaded eye bolt, there is a chamfer, which helps the installation more easily.

- After galvanizing eye bolt, Rax Industry workers sprinkle oil on the thread to guarantee a smooth installation

- All the steel rod raw materials for oval eye bolts are new and standard, it’s not recycled.

- Before packing, all the drop forged eye bolts are tested for galvanization thickness and load strength.

Advantages of Forged Eye Bolts

- Offers outstanding strength

- Highly durable

- Undergoes heat treatment, quenching, and tempering

- Excellent impact handling.

Forged Eye Bolts Manufacturing Process

Drop forging is a form of the metal fabrication process, that assists in uniformly molding a heated piece of metal, referred to as ingot.

The method entails forming a block of metal, by giving it repeated blows using a die or hammer.

Technical drawing of forged eye bolt

This is achieved by lifting and then dropping the die or hammer on the piece of metal, as a result flattening or shaping it to the required structure.

Production of drop forged eye bolts involves careful estimation of the metal block.

In some instances, you will include extra techniques like machining, in order to achieve the desired tolerance.

The method uses dies composed of high alloy steel referred to as tool steel.

This type of dies is resistant to everyday wear and tear, and are as well able to sustain recurrent sharp heating and cooling cycles.

In this method, you design the die so that it is in two halves.

The upper half, referred to as the hammer, is tightened to the raised block, which you drop into the steel bar.

The lower half, called the anvil, is a stationary die that you use against the steel block you are forging.

Open-die is another hot drop forging method of producing forged eye bolts. In this technique, the dies do not wholly surround the steel rod.

This die type is commonly flat unlike cutting or contoured dies and is way better than ordinary dies.

The open die technique allows for the steel block expansion when you hammer it to the desired thickness.

Die drop forging procedure involves the making of dies, billet cutting, and heating, metal drop forging, trimming, heat treating of the eye bolt, shot blasting, bolt machining, bolt surface treatment, and inspection.

Let’s look at the process of hot drop forging step by step:

Step 1: Dies design and making

Fabrication of the dies is the starting point of drop forging process.

You will first have to design and create the dies as per the drawing.

The dies should constitute, forging, trimming, and flat die.

However, the flat die is not essential, since it just helps in flattening the eye bolt to guarantee geometric tolerance.

Step 2: Billet cutting and heating

We usually prepare popularly used materials.

Cut the billet to the required size then heat them up using a medium frequency furnace.

Take the heated steel to a metal frame in preparation for forging.

Step 3. Drop Forging

First, attach the upper and lower forging dies to the forging press anvil.

Place the billet between the forging dies, and then press them at high-speed severally till you obtain the desired shape.

Step 4. Trimming

You will observe redundant flash about the produced blanks, thus flash removal is equally an essential step.

Set up the trimming dies below the punching equipment, and then remove the flash by pressing the drop forging blanks one by one.

Step 5: Heat Treatment

Heat treatment will aid in achieving the desired hardness and mechanical features.

The processes of heat treatment include normalization, annealing, tempering, quenching, solution treatment, hardening among others.

Step 6: Shot Blasting

Shot blasting the drop hot forged eye bolts make them smoother and brighter – you will have a superior surface finish.

Typically, the surface finish of drop forged parts will be better than that of precision casting.

Step 7: Machining

If drop forging procedure is not sufficient to attain the tolerance you desire, then machining will come in handy.

Machining can be done using different equipment including boring, milling, drilling, grinding, and CNC machine among others.

Step 8: Threading

Before galvanizing our forged eye bolts, we thread and enable with hex nuts that we tap unshapely.

You can find special thread and shank sizes for forged eye bolts.

According to your needs, you can choose appropriately.

Step 9: Surface treatment

Most drops forged eye bolts manufacturers only perform oil or water anti-rust on the forged eye bolt’s surface if there is no specific requirement.

The surface treatment method for our forged eye bolts is hot-dip galvanization.

The galvanized steel eye bolts contain no zinc block.

However, we can as well do other surface treatment procedures such as powder coating, painting, electro-plating among others based on the customer’s requirements.

Step 10: Final inspection

To guarantee superior quality, you must do a dimension inspection.

You also need to inspect the chemical composition and mechanical characteristics.

Step 10: Packaging and delivery

Typically, we pack Rax Industry forged eye bolts in poly bags and place them in a secure wooden case.

We can also customize the packaging to meet your demands.

Step-by-step Forged Eye Bolt Installation Process

Just as critical as selecting the correct forged eye bolt, the right installation and maintenance are as important in ensuring the safety of the workplace.

Step 1

First, establish the thickness of the object you will be fixing the forged eye bolt through.

Do a comparison of the two measurements and verify that the drop forged eye bolt length is not longer than the material’s thickness.

Step 2

Then, select a forged eye bolt having a shank long sufficiently to enable protrusion of the bolt on the backside.

This facilitates the tightening of the nut appropriately.

Step 3

Dispel any sawdust out of the drilled hole, put the drop forged eye bolt into the hole and twist it in a clockwise direction to install.

Keep turning in the prescribed direction till the section of the threads of the bolt protrudes on the back side of the material.

Step 4

From the protruding end, tighten the drop forged eye bolt to the object using the issued nut.

In case the unthreaded section of the shank extends below the bottom end and does not permit fastening of the nut, use a washer to bridge the space of the unthreaded segment of the shank.

General Safety Precautions

- Never work with an eye bolt that exhibits symptoms of wear or damage.

- Never work with a drop forged eye bolt with an elongated or bent shank or eye.

- Always ensure that the receiving hole and threads on the shank are clean.

- Never grind, cut, or machine forged eye bolt.

Frequently Asked Questions (FAQs)

What is a forged eye bolt?

Forged eye bolt is a type of fastener widely used on wooden poles to support thimbles, clevises, links, and dead end insulators in electric power lines or overhead lines. It is also called a drop forged eye bolt.

Forged Eye bolt is hot drop forged in one piece, it is also called a drop forged eye bolt.

What are the types of forged eye bolts?

According to the designs, there are 3 types:

- Regular oval eyebolt: Assembled with one square nut.

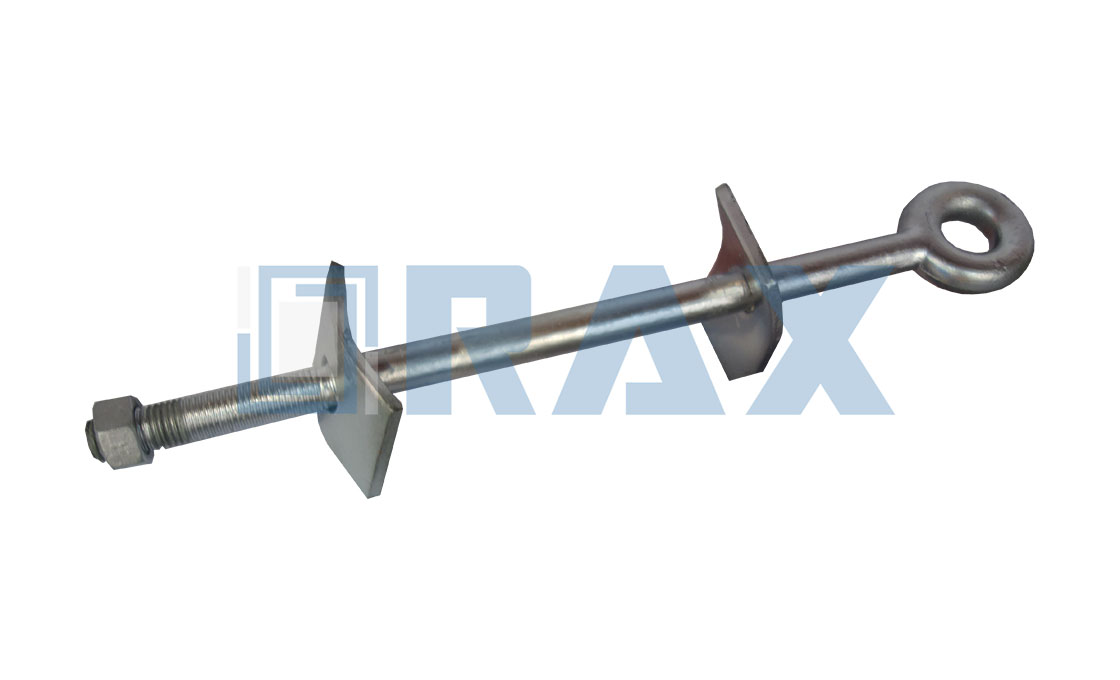

- Double arming oval eyebolt: A combination double arming bolt and an eyebolt, assembled with three square nuts.

- Shoulder eyebolt: With an integral shoulder to reduce stress on wood poles.

What should I look into when choosing forged eye bolts?

Main technical specifications for eye bolts include:

- Maximum load capacity – The greatest load which a forged eye bolt can manage.

- Shank length Threaded length

- Eye inside diameter

- Total weight

- Eye thickness or eye section diameter

Conclusion

As you can see, forged eye bolts play an integral role in pole line hardware installation.

With the information in this guide, it is now easy for you to shop for a suitable forged eye bolt.

In comparison to other drop forged eye bolt manufacturers, Rax Industry understands how to control the high standards and boost efficiency.

Contact us today for cost-competitive forged eye bolts.