Power fittings are widely used in transmission lines, communication lines, and utility pole lines.

As an outstanding manufacturer and supplier, Rax Industry can supply you with samples of electric power fitting to help you participate in the tender, such as guy grip, cross arm, post insulator, pole top, anchor rod, types of bolts, and so on. All the electric power fittings are manufactured in accordance with the specified standards ASTM.

The steel used in the manufacture of the plates is Q235. The steel to be used for the manufacture of the hexagon head coach screws like square head bolt oval eye bolt have chemical properties which give at least the mechanical properties of steel grade 4,8 to EN 898-1, steel grade 4,8 is required steel with minimum tensile strength 420 N/mm2.

Experience work with TNB

Why Rax Industry is Trusted By 1000+ American clients

Dominica market uses the electric power fitting include as below:

Cross arm 1830 and 2440, alley arm, steel brace, square head machine bolt, Bolt Eye, Stay Rod, Stay Plate, and so on. These electric power fittings are mainly used to connect and support the line. The finish is hot-dip galvanized

Quality control:

1.Dimension/Drilling: All steel items to be shaped, dimensioned, and drilled to the specified drawings

2.the steel tubes used on the street light arm to be constructed as per EN10255. All open ends of tubes to be internally chamfered 45 to half the wall thickness in order to reduce cable scarfing

3.Tolerances

Tolerances on length of all members to be +2mm. Tolerances on circular hollow sections to be in accordance with EN 10210-2.

4.Galvanising

All steel members to be hot-dip galvanised according to EN ISO 1461 and shall withstand the tests set out in this Standard. Following necessary treatment and after all sawing, shearing, drilling, punching, grinding, bending, and machining is completed, the mean coating thickness (minimum) and local coating thickness (minimum) shall be as specified in Table 3 of EN ISO 1461.

The method of Steel treatment prior to galvanising to be specified and a full description to be given. All bolts and nuts to be hot-dip galvanised as well. The zinc coating to be uniform, clean, smooth, and as free from spangle as possible. The zinc coating thickness shall be as specified in Table 4 of EN ISO 1461.

5.Welding

Welding shall be carried out in accordance with EN 1011-1.After welding and before galvanising, welds shall be thoroughly cleaned to remove slag and spatter, particular attention being paid to the toes of welds and to the prevention of entrapment of slag and spatter. Sandblasting or other methods of cleaning welds.

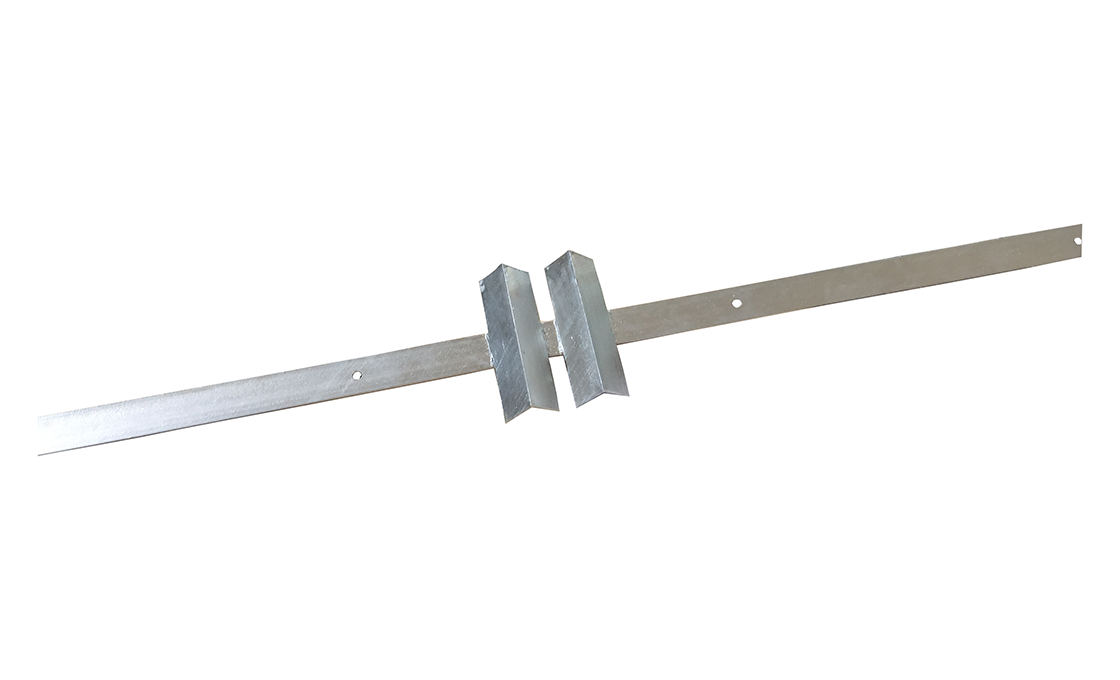

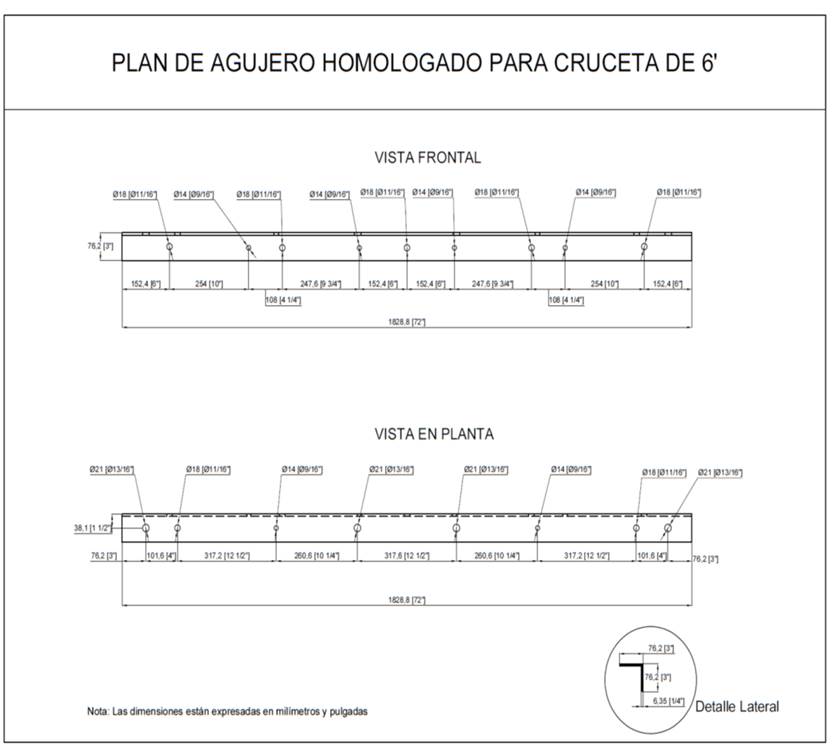

cross arm

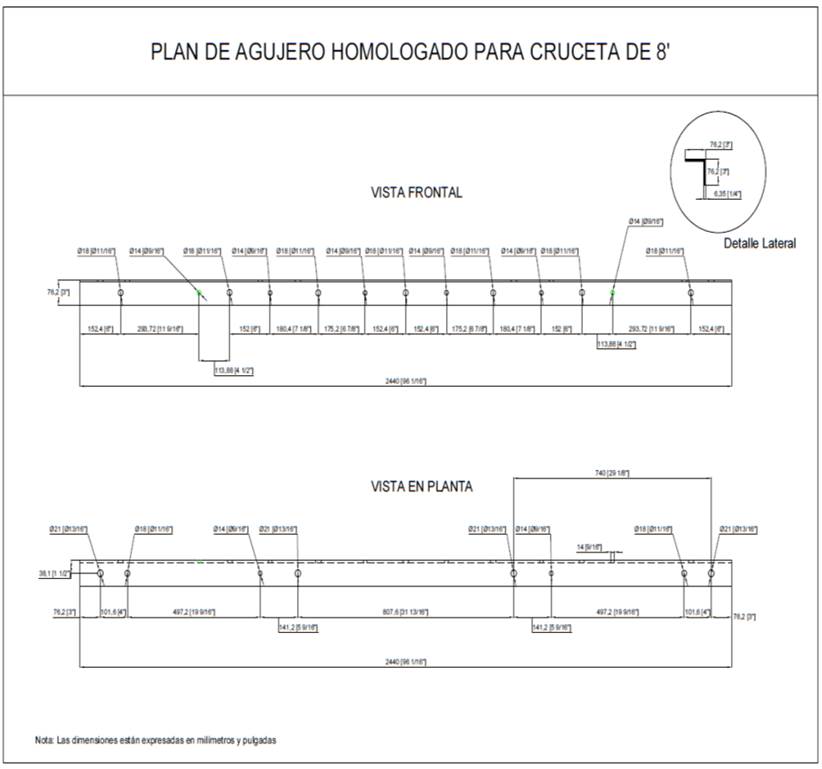

Rax Industry cross arms which are supplied to edenorte, edeeste, and edesur have different types. The C-20C cross arm length is 1828mm, the thickness is 6.35mm. The C-20D cross arm is 2440mm, the thickness is 6.35mm, width is 75mm. The distance between each hole is fully according to the drawing. The tolerance is +-5%.

C-20C drawing:

C-20D DRAWING:

C-20D DRAWING:

Sample testing pictures:

Sample testing pictures:

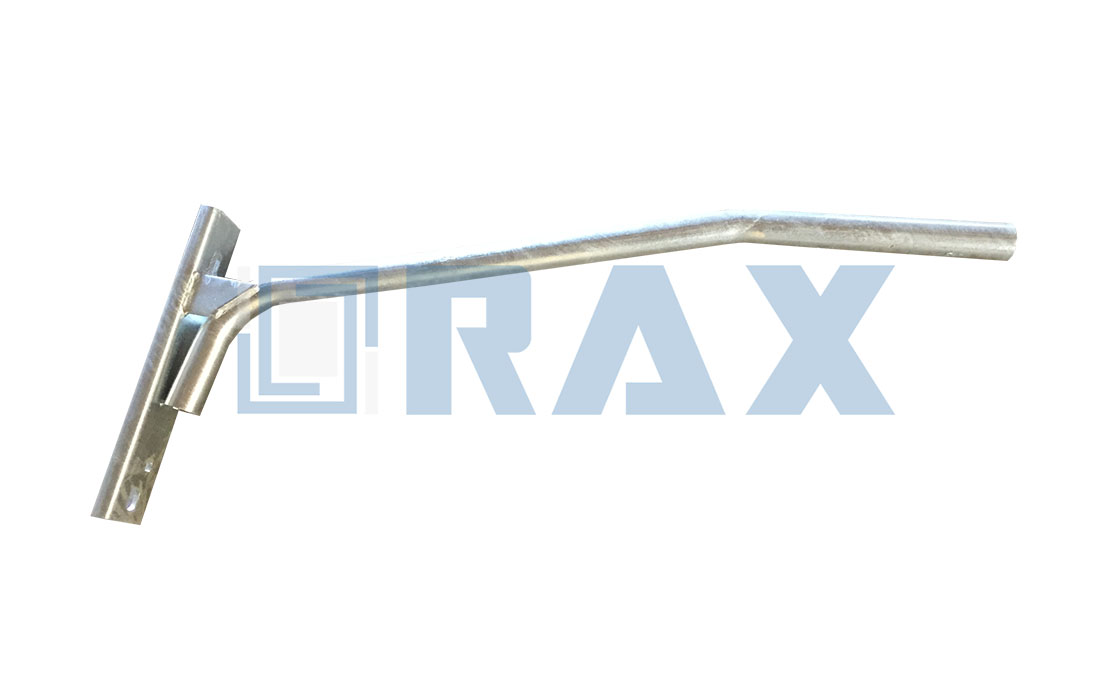

Alley arm

Alley arms, cross arms mounted to one side of the pole, require rigid bracing to ensure proper alignment of power distribution and transmission lines. Sturdy MPS angle steel alley arm braces mount at a 45-degree angle and come complete with a solidly welded lineman step.

These braces are mounted to the side of the arm by a machine bolt and attached to the pole with two 1/2″ lag screws.

| Basic date | |||||

| Catalog NO. | STEEL SIZE | Length | Galvanized thickness | Approx weight | Remark |

| JY-L-01 | 1 3/4〞x1 3/4〞x3/16〞 | 60“ | >85µm | 6KG | B-7A |

| JY-L-02 | 1 3/4″ X 1 3/4″ X 3/16″ | 84“ | >85µm | 8.5KG | B-7B |

| JY-L-03 | 1 3/4″ X 1 3/4″ X 3/16″ | 120″ | >85µm | 12KG | B-7C |

| JY-L-04 | 1 3/4″ X 1 3/4″ X 3/16″ | 120“ | >85µm | 12KG | B-10C |

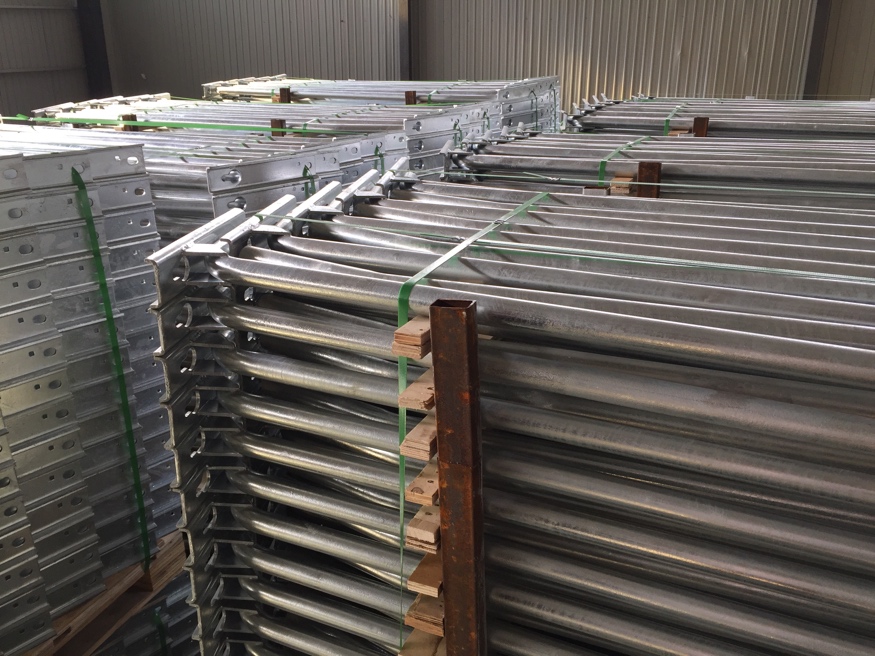

Packing pictures:

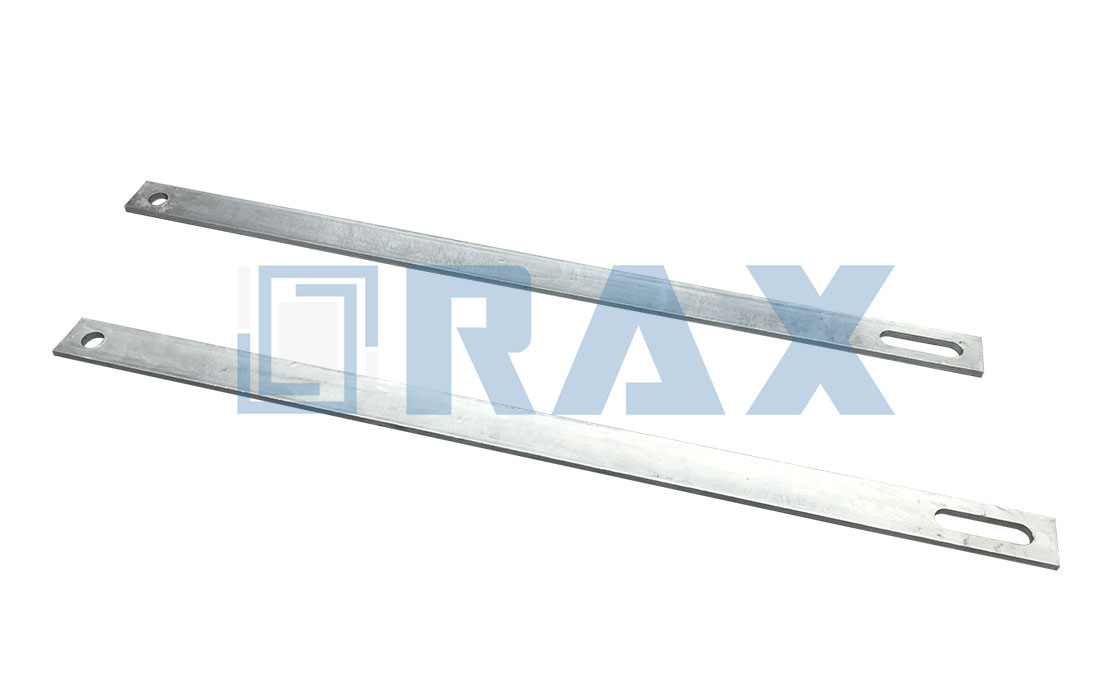

Crossarm Brace

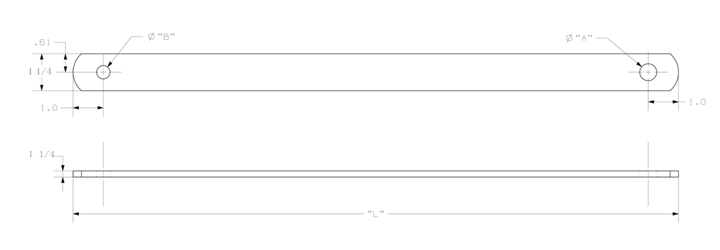

Have rounded ends and are punched at one end with a 9/16″ hole, with a 7/16″ hole at the other end. Holes punched 1inch from brace end to center of the hole. Hot-dip galvanized>85µm.

Have rounded ends and are punched at one end with a 9/16″ hole, with a 7/16″ hole at the other end. Holes punched 1inch from brace end to center of the hole. Hot-dip galvanized>85µm.

Standard: ASTM 123 – 78

Material: Galvanized Steel

| Basic date | ||||||

| Catalog NO. | STEEL SIZE | Length(L) | “A” | “B” | Approx weight | Remark |

| JY-B-7020 | 1 1/4″ X1/4″ | 20 | 9/16 | 7/16 | 0.76KG | |

| JY- B-7026 | 1 1/4″ X1/4″ | 26 | 9/16 | 7/16 | 0.99 KG | |

| JY- B-7028 | 1 1/4″ X1/4″ | 28 | 9/16 | 7/16 | 1.07 KG | B-6A |

| JY- B-7030 | 1 1/4″ X1/4″ | 30 | 9/16 | 7/16 | 1.15 KG | |

| JY- B-7032 | 1 1/4″ X1/4″ | 32 | 9/16 | 7/16 | 1.22 KG | |

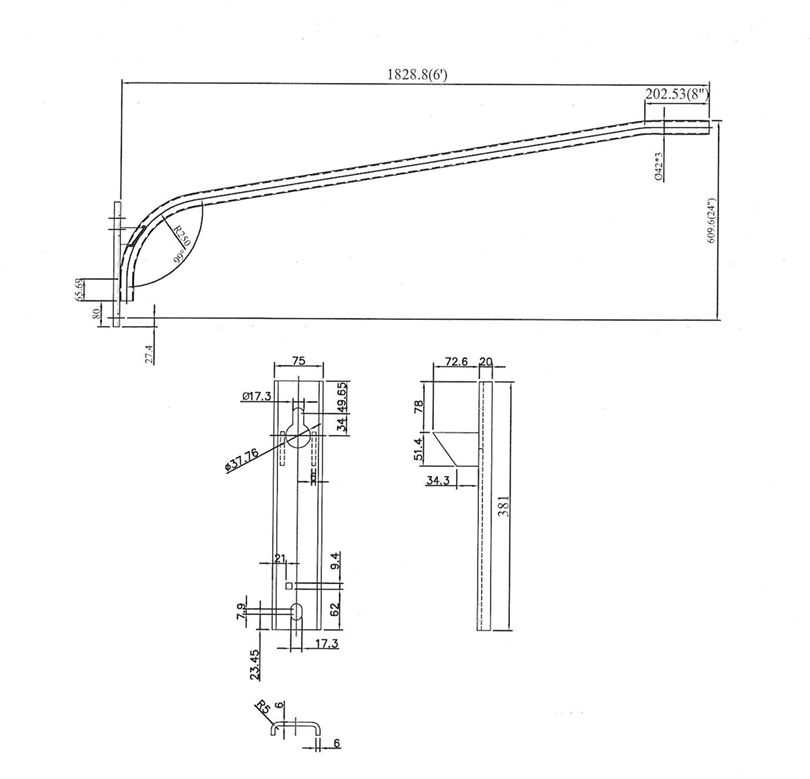

Street light arm

Compare BR-1A BR-1B BR-1C:

The drawings and datasheet:

The street light arm packing picture:

The street light arm packing picture:

Frequently Asked Questions (FAQs)

What is electric power fitting?

Power fittings are all kinds of accessories which used to connect or support the electric device so that the pole line will realize the power delivery.

What is the application of the electric power fitting?

It is widely used in the transmission line, communication lines, and utility pole lines.

What are the types of power fitting?

There are hundreds of types, here are some key ones:

- Anchor Rod

- Ball Clevis

- Guy Clamp

- Pole Top Bracket

- Secondary Clevis

- Socket Clevis

- Steel Cross Arm

What is the key consideration when choosing products?

Here are some factors that play a huge role when choosing products.

- Type of Material

- Design of the Accessory

- Safety Rating

- Type of Application

- Resistance to Various Conditions

- Cost of Buying