Insulation Piercing Connector

Insulation Piercing Connectors (IPCs) are used to make branch connections from an existing cable without requiring stripping of the cable insulation. They can be used for indoor and outdoor connections.

When using insulation piercing connectors to create a new connection from an existing supply line it is not necessary to isolate the supply. The IPCs are designed to be clamped onto the cable where the piercing blades pass through the cable insulation and connect with the conductor in the cable.

One of the most common applications of this type of connector is in street light installations where they are used to establish a power supply connection from the main supply line to the street light. IPCs also find use in distribution boxes, jumper connections, and other branch-off electrical connections.

Due to the structure of piercing connectors, they can be installed without the use of special tools. Their structure also includes sealing which helps to ensure that the connection between the main line and the IPC is safe from environmental hazards.

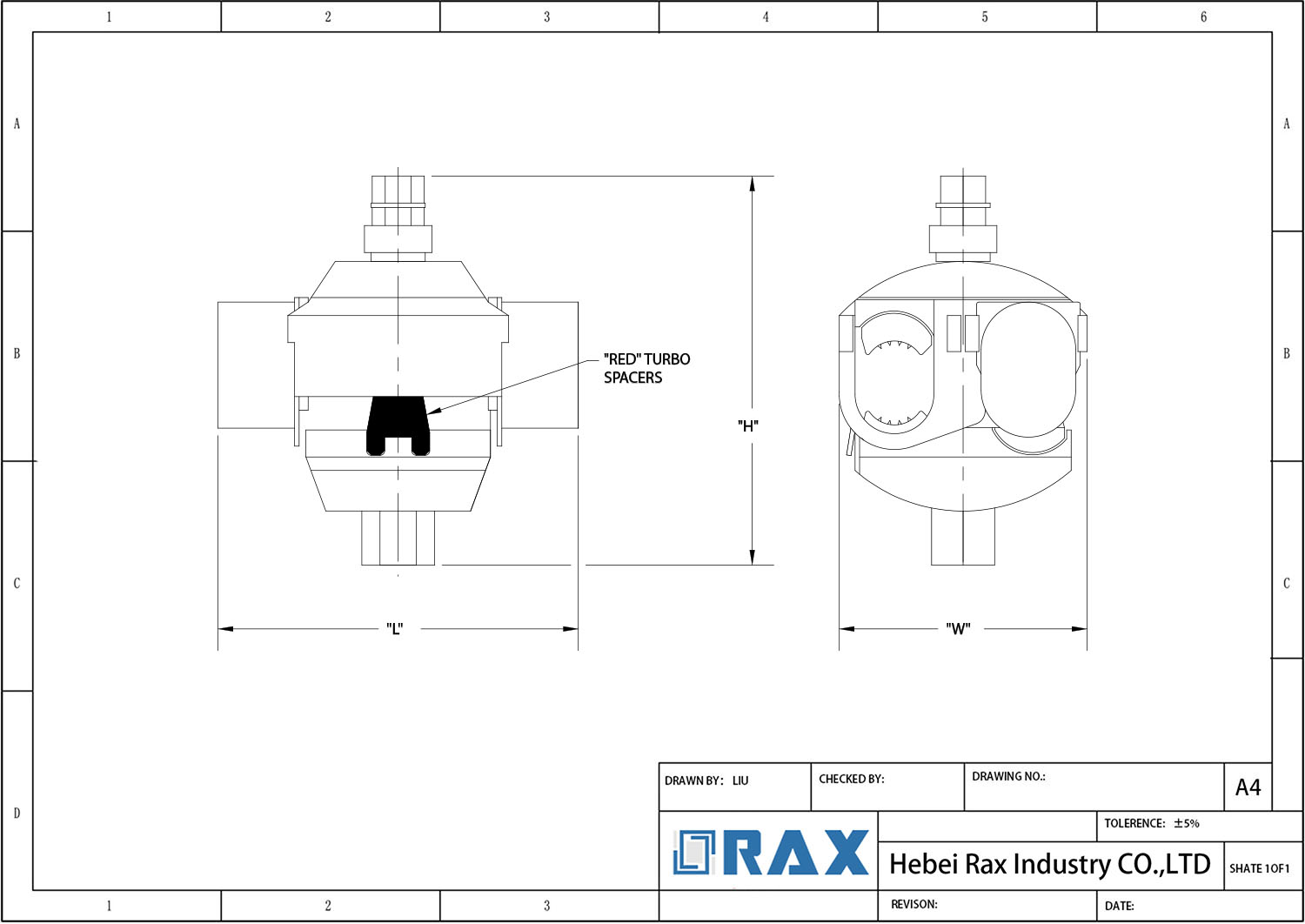

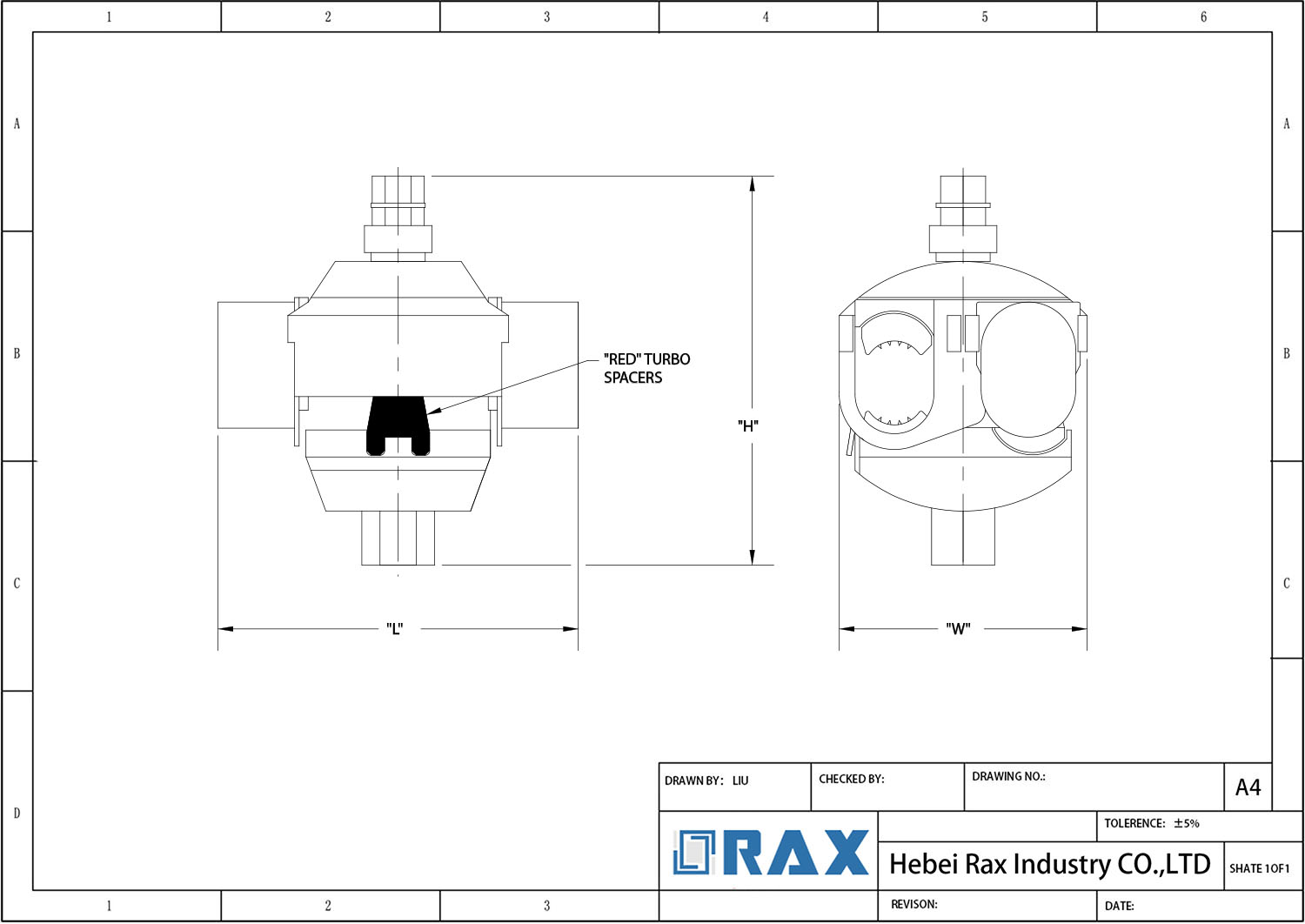

Insulation Piercing Connector Drawing

Insulation Piercing Connector – The Ultimate Guide

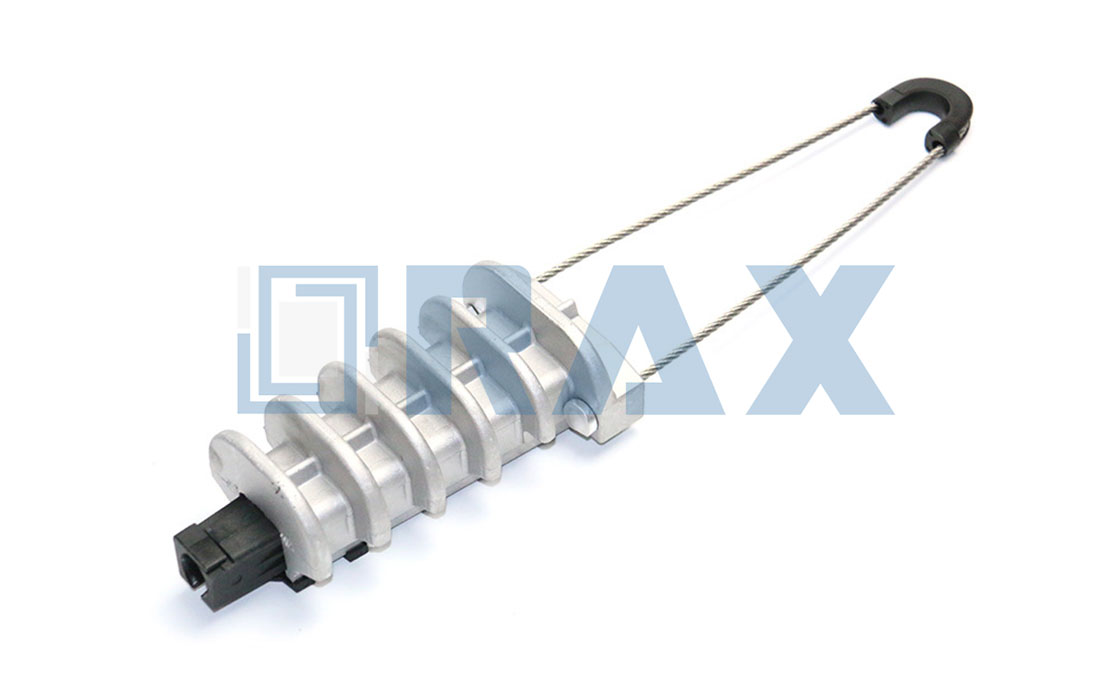

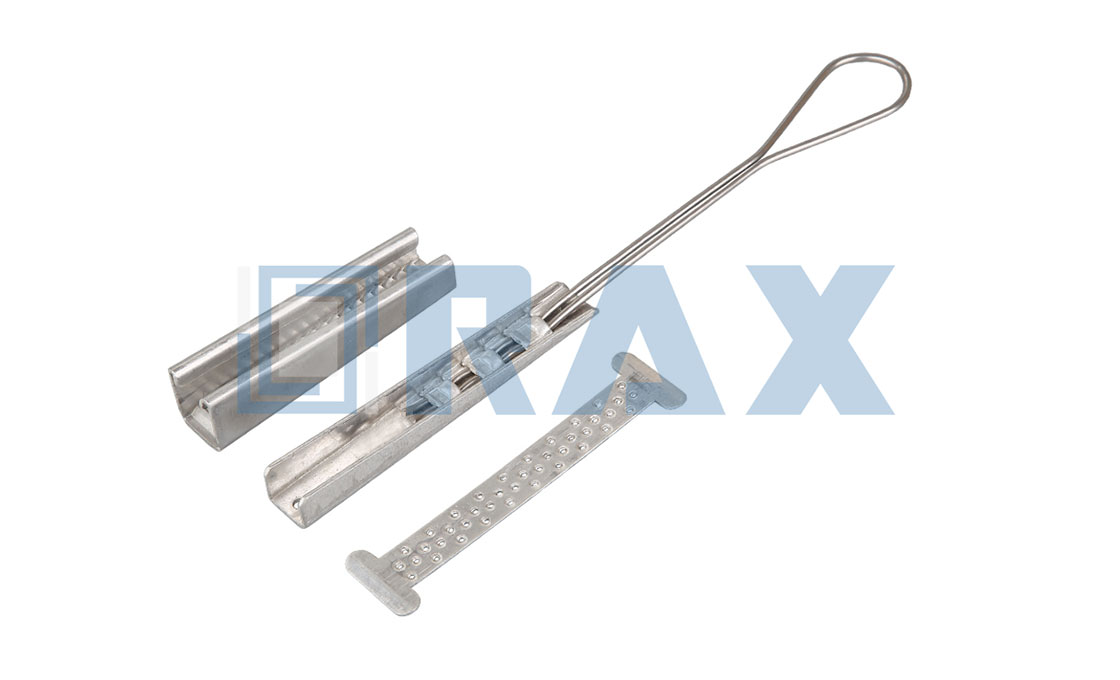

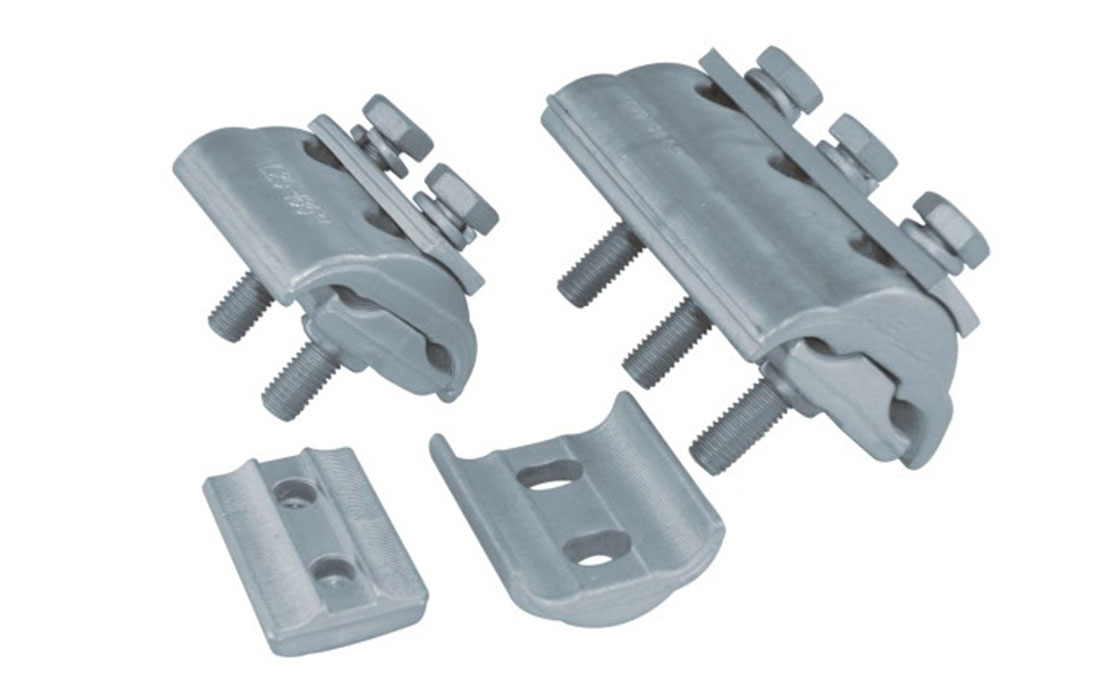

The structure of an insulation piercing connector includes a lower and upper blade that is separated with a screw and connected with a torque nut. When clamped onto the cable, the torque nut ensures that the piercing blades make contact with the conductor ensuring that there is stable electrical transmission.

The structure of an insulation piercing connector includes a lower and upper blade that is separated with a screw and connected with a torque nut. When clamped onto the cable, the torque nut ensures that the piercing blades make contact with the conductor ensuring that there is stable electrical transmission.

The installation can be done by using a socket wrench to twist the torque nut which applies pressure to the piercing blades to achieve connection between the conductor in the cable and the IPC.

Since insulation piercing connectors need to efficiently conduct electricity, they are made from copper or aluminum. These materials are efficient conductors and can easily transmit electricity when they come into contact with the conductor.

For safety, the piercing blades are typically insulated with nonconductive sealing material. This is to ensure that when the IPCs outer surface comes into contact with another object or person there will be no voltage transfer.

To accommodate different types of applications and uses, insulation piercing connectors are available in single or double bolt options as well as different sizes.

The Structure of IPCs

- Piercing blade:

This is the main component of the connector. The piercing blade establishes the connection with the main line by piercing the insulation and connecting with the conductor in the cable. The blade is made of highly conductive material with a sharp pointed end to enable it to penetrate the cable insulation and establish a connection.

- Insulation material

To protect the piercing blade, IPCs are designed with insulation housing made of rubber or plastic to enclose the piercing blade. The insulation housing material is typically non-conductive to ensure safety by ensuring that the piercing blades come into contact with objects or persons.

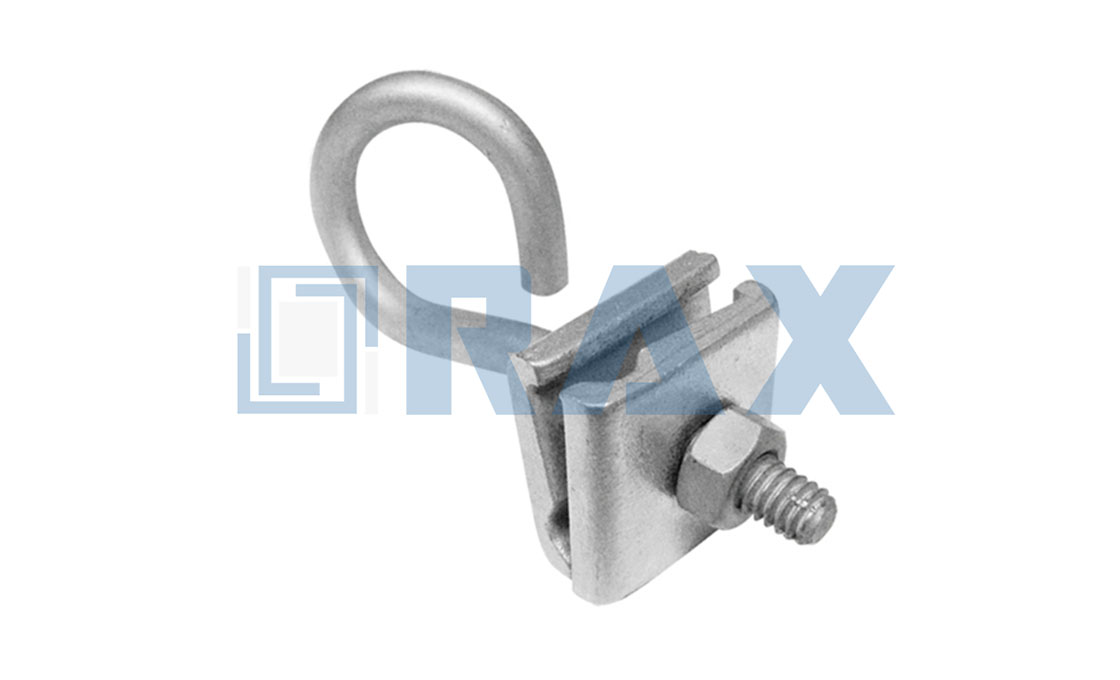

- Clamping mechanism

IPCs are designed to clamp onto the power line so they need a clamping mechanism. This may include screws, bolts or other fasteners that are typically tightened to securely connect the IPC with the cable.

- Terminal connectors

Screw terminals, crimp connectors, and other types of connectors are required to enable the attachment of additional wires or devices to the clamp.

- Sealing components

To protect the IPCs against damage caused by environmental wear such as corrosion and oxidation, sealing components are used to seal the connection point. This creates a barrier against water, dirt, and any other contaminants that can interfere with the connection and cause interruptions.

Main Applications of Insulation Piercing Connectors

- Street lights

IPCs are used to tap the AB cable and establish a new connection for the street light. The piercing connector pierces the insulation of the cable to make a conductive path with the conductor inside the cable. This creates an electrical connection to the service line supplying power to the street light.

- Multi-tap connections in domestic electrical systems

When connecting power to a household from a distribution line, the piercing connector is used to tap the main AB cable creating an electrical connection from the main line to the household. IPCs can be used to make multiple connections for more than one household using the multiport connectors.

- Distribution box connections

Low voltage distribution boxes can be connected and charged using piercing connectors to connect to the main supply line.

- Jumper connections

IPCs are also utilized in jumper or T connections where they can be used to take out another connection for a new distribution line, creating a low voltage network.

Advantages of Insulation Piercing Connectors

- Easy installation

IPCs do not require special equipment for installation. They can be installed without cutting off the main cable or stripping the insulation layer making it easy to create new connections with high and low-voltage distribution lines.

- Cost effective

Since no stripping of cables or special equipment is required during installation, IPCs are typically more cost-effective than traditional methods of electrical connection. The ease of installation helps to minimize labor and time costs, especially for large-scale installations.

- Long-lasting performance

IPCs are designed to last with protective insulation protecting the conductors from wear and tear caused by environmental elements. The build and design ensure that the piercing connectors are corrosion-resistant, twist-resistant, flame-retardant, and shockproof for reliable performance and long-term durability.

- Easy Maintenance

IPC connections are easily accessible in case of downtime or interruptions in supply. This makes maintenance easy since it is possible to identify and rectify any connection points that have issues with ease.

- Flexible

Insulation piercing connectors are flexible and can be used for various applications where conductors are made of copper or aluminium. They allow for copper to copper or copper to aluminium combinations. They can also accommodate copper to aluminium combinations. a combinations, including copper-to-copper, copper-to-aluminium, and aluminium-to-aluminium.

- Low risk of failure or disruption

Due to the excellent design and solid construction, IPCs provide stable and secure connections. There is low risk of disruptions or failure since the piercing connectors have a torque nut that applies constant contact pressure to the conductors to ensure a stable electrical connection.

Frequently Asked Questions

What are the main uses of insulation piercing connectors?

Insulation Piercing Connectors are electrical connectors that make it possible to connect new connections to an existing power line. They establish a secure connection by piercing the insulation of the cable and connecting with its conductor to create a secure and stable connection.

Can you get electrocuted by touching the outer structure of the insulation piercing connector?

No, to protect the piercing blades and ensure there is no voltage transference the piercing blades of the insulation piercing connector is typically insulated with materials like rubber which are poor conductors of electricity. This ensures that objects or individuals coming into contact with the outer surface of the IPC will not be electrocuted.

Can insulation piercing connectors be reused after the first installation?

No, once an IPC is installed it cannot be reused. They are designed for single use so when establishing a new connection, it is best to use a new IPC to ensure the integrity and stability of the connection.

During installation, is the cable stripped before installing the IPC?

No, stripping of the cable is not required. IPCs are designed with special alloy blades that can efficiently pierce the insulation of the cable and reach the conductor within.

What type of equipment is required for installation of IPCs?

Installation of IPCs can be done using just a wrench. The design of the IPC allows easy installation with no need for special equipment since the piercing connector is simply clamped onto the main cable where the connection is being made.

In domestic electrical distribution projects can you use IPCs to create multiple connections?

Yes, when connecting multiple households to the main powerline, insulation piercing connectors can be used to create multiple connections. Multiport insulation piercing connectors can be used in cases where more than one connection is required.