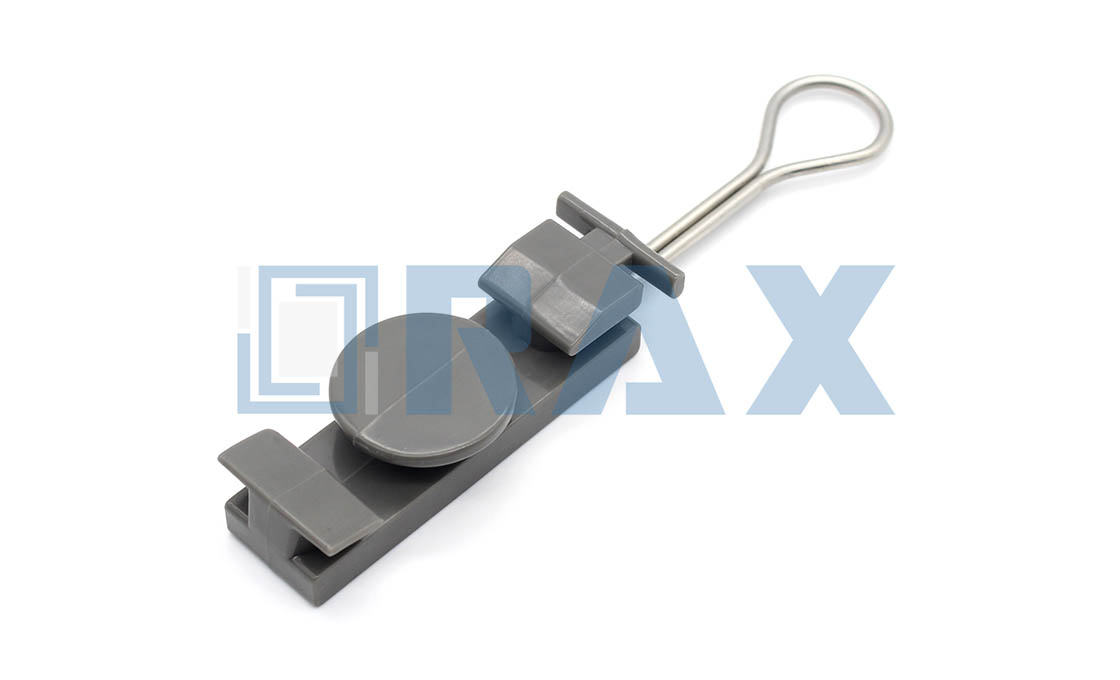

Drop Wire Clamp

A drop wire clamp is deployed for supporting one and two pair fiber drop wires at house hooks, span clamps, drive rivets, and different drop attachments. Moreover, it is used for supporting both aerial services ends drop span at building and the messenger strand. Most of the drop wire clamps are removable.

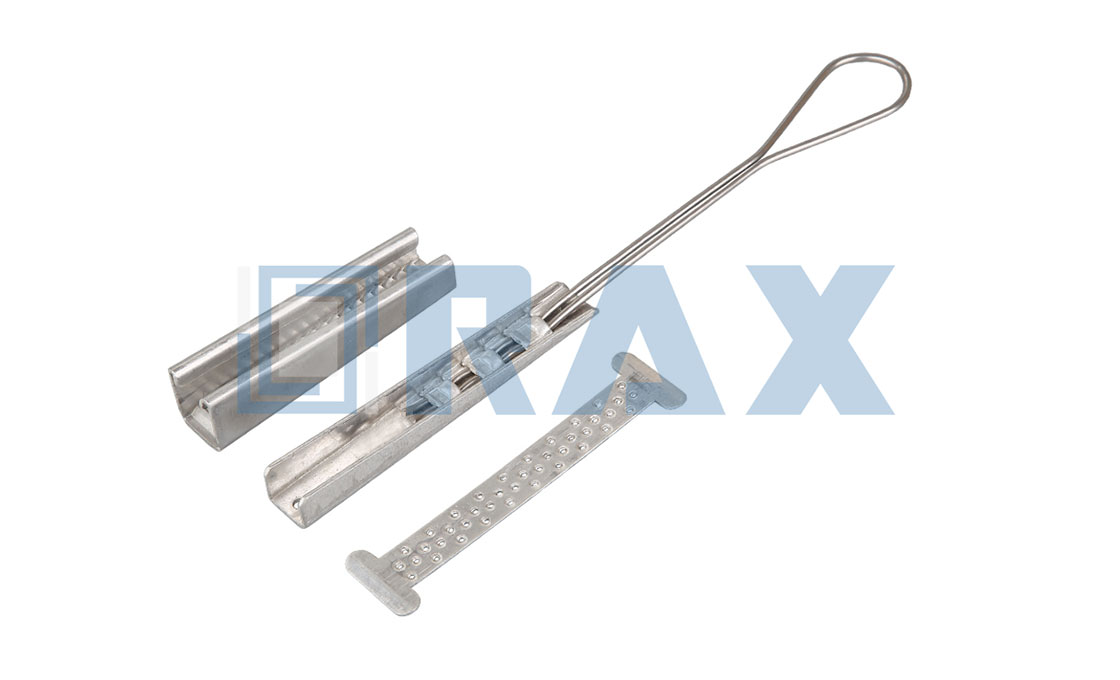

A drop wire clamp beneficial for a double-stranded figure type cable comes with a trough and a plate (aperture) plate lowering from a trough’s end so that one clamp is suspended from an appropriate anchor. This trough is sized for accepting the cable without the need for threading and without any compression on the cable portion that carries the signal. The line is maintained in this trough by wrapping the eliminated support strand surrounding the channel.

A drop wire for a cable including a support strand as well as a strand that carries a signal, the clamp is composed of the following:

An open trough that accepts the cable not having the threads, wherein the trough’s available portion is better defined through the edges, the trough edges being supported by means for the maintenance of support strand that gets separated from the cable and is wrapped over the trough to keep the thread in the track; also, the means for engaging the support, so the clamp is better support from the needed structure. On the other hand, a plate gets extended from a trough’s one end and supports the means for engagement.

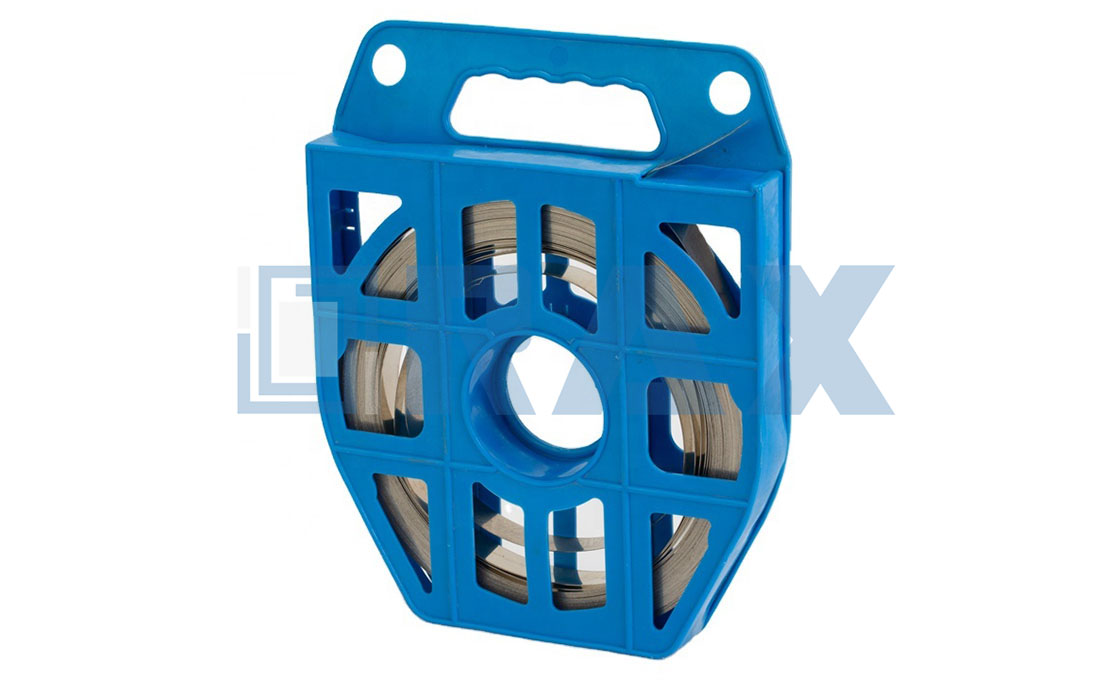

As a professional manufacturer, supplier, and exporter, Jingyoung can support all sizes of drop wire clamps, we can also customize them according to your designs.

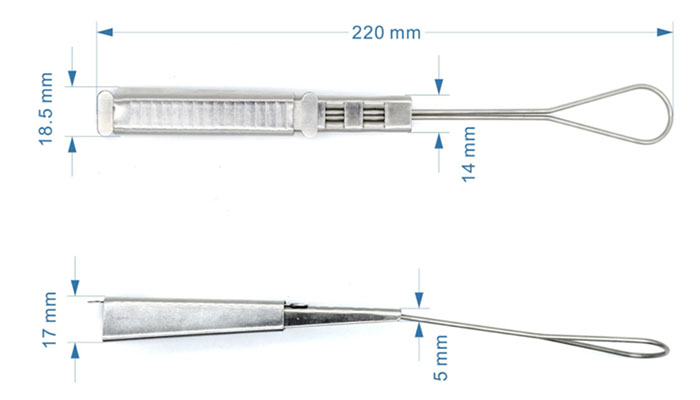

Parts No. | Drop Cable | Material | Shim Type |

CWC-2PRAD | 1-2Pair | Aluminum | Dimpled |

CWC-2PRSD | 1-2Pair | Stainless | Dimpled |

CWC-2PRAS | 1-2Pair | Aluminum | Serrated |

CWC-2PRSS | 1-2Pair | Stainless | Serrated |

CWC-2PRAD | 1-2Pair | Aluminum | Plastic |

CWC-2PRSD | 1-2Pair | Stainless | Plastic |

CWC-6PRAD | 6 Pair | Aluminum | Dimpled |

CWC-6PRSD | 6 Pair | Stainless | Dimpled |

CWC-6PRSS | 6 Pair | Stainless | Serrated |

A Complete Guide to Drop Wire Clamps

Drop wire clamps are essential components in telecommunications and electrical installations, designed to securely attach drop wires to poles, buildings, or other support structures. These clamps play a crucial role in ensuring the stability and integrity of overhead wiring systems, particularly for fiber optic and coaxial cables.

What is a Drop Wire Clamp?

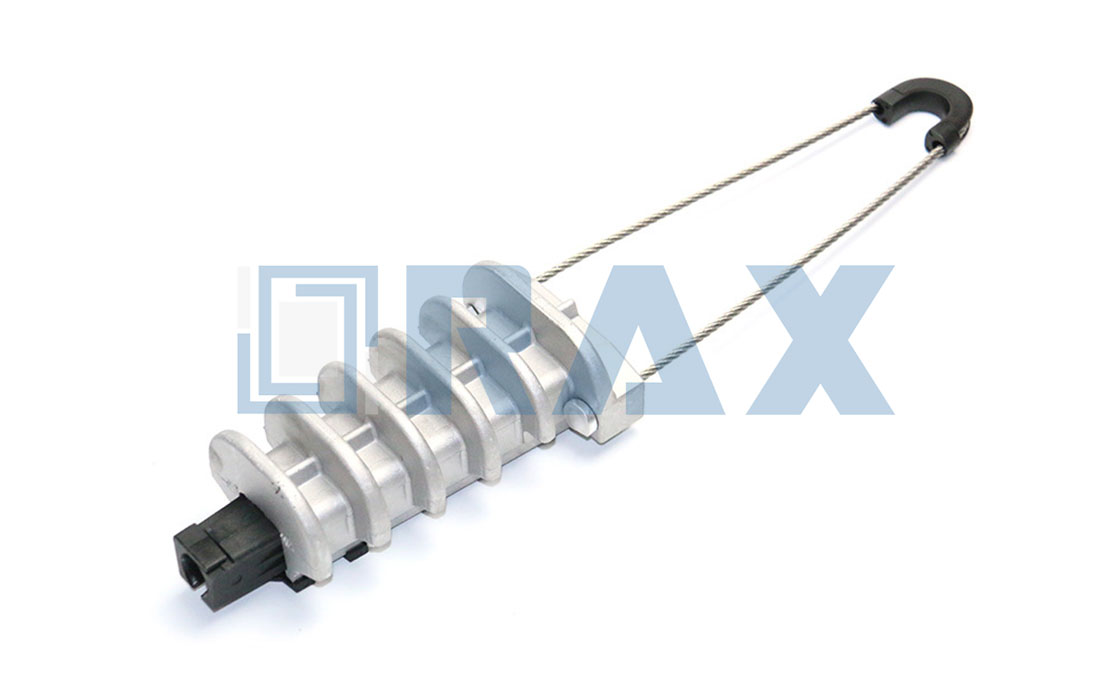

A drop wire clamp is a specialized device used to secure one or two pairs of drop wires at various attachment points, such as span clamps and drive hooks. It is designed to support the weight of the cable while minimizing signal loss and maintaining proper tension throughout the installation. The clamp typically consists of a durable body that grips the wire securely, along with additional components that enhance its functionality.

A drop wire clamp is a specialized device used to secure one or two pairs of drop wires at various attachment points, such as span clamps and drive hooks. It is designed to support the weight of the cable while minimizing signal loss and maintaining proper tension throughout the installation. The clamp typically consists of a durable body that grips the wire securely, along with additional components that enhance its functionality.

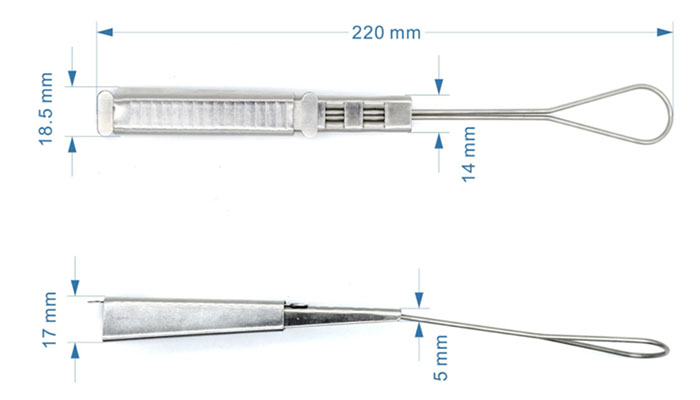

Key Components of Drop Wire Clamps

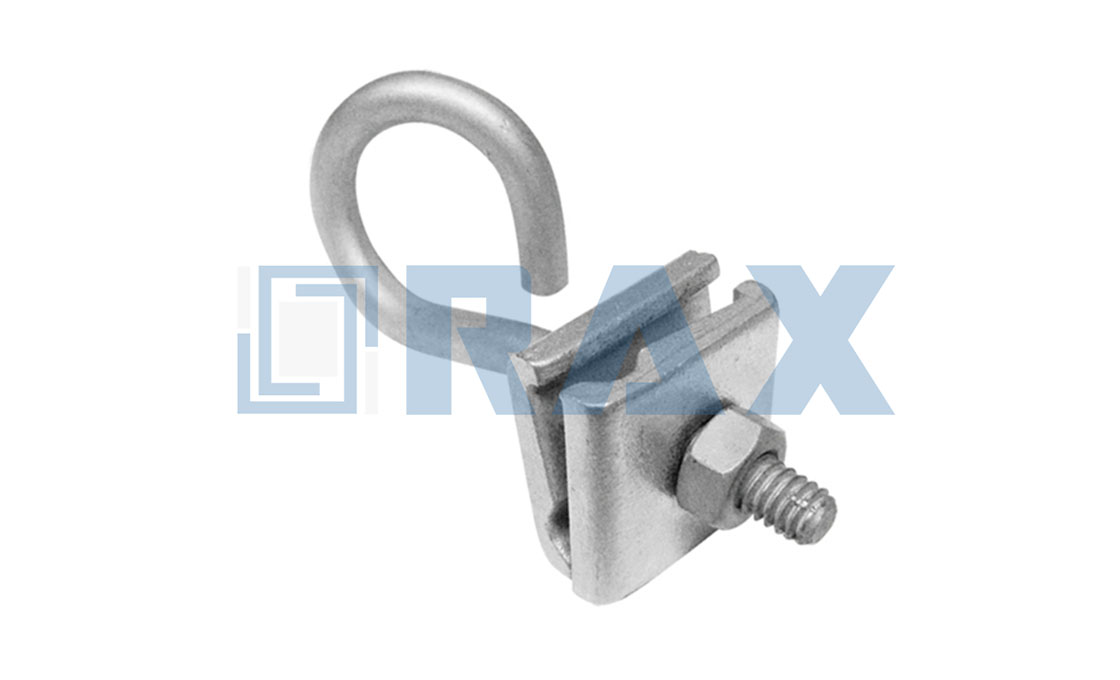

- Clamp Body: The main component that holds the drop wire in place. It is usually made from durable materials like metal or high-strength plastic.

- Bail or Retainer: Provides additional support to hold the drop wire securely in position.

- Mounting Hardware: Includes nuts, screws, and bolts used to attach the clamp to poles or buildings.

- Strain Relief Device: Helps prevent damage to the drop wire by relieving tension and stress during installation.

- Insulation Coating: Protects the wire’s insulation from damage during installation and operation.

| Component | Description |

|---|---|

| Clamp Body | Holds the drop wire securely |

| Bail | Provides additional support |

| Mounting Hardware | Secures the clamp to supporting structures |

| Strain Relief Device | Prevents damage from excessive tension |

| Insulation Coating | Protects wire insulation |

How Does a Drop Wire Clamp Work?

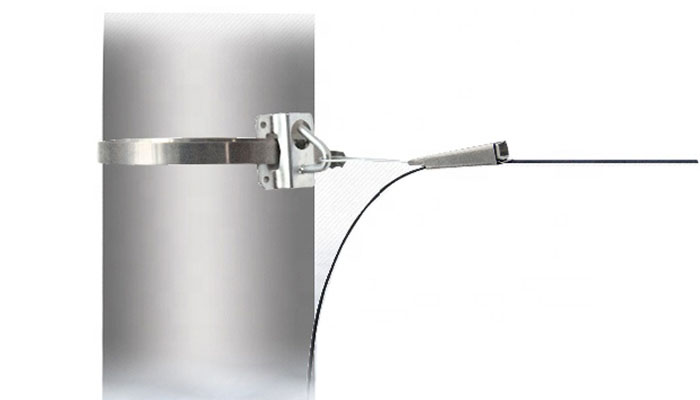

The primary function of a drop wire clamp is to attach and support drop wires without compromising their signal transmission capabilities. The clamp secures the cable in a suspended manner, allowing it to hang freely while maintaining proper tension. This is critical for preventing sagging or excessive movement caused by wind or other environmental factors.

The primary function of a drop wire clamp is to attach and support drop wires without compromising their signal transmission capabilities. The clamp secures the cable in a suspended manner, allowing it to hang freely while maintaining proper tension. This is critical for preventing sagging or excessive movement caused by wind or other environmental factors.

Installation Process

Installing a drop wire clamp involves several steps:

- Preparation: Ensure that the installation site is clean and free from debris. Gather all necessary tools and safety equipment.

- Select Appropriate Clamp: Choose a drop wire clamp suitable for the type of cable being used (e.g., fiber optic or coaxial) and its specific application requirements.

- Positioning: Place the clamp at the desired location along the power transmission line or service drop. Ensure it is properly aligned according to installation guidelines.

- Securing the Clamp: Use appropriate mounting hardware to attach the drop wire clamp to the supporting structure or pole securely.

- Insert Drop Wire: Carefully insert the drop wire into the clamp, ensuring it is properly seated within the grooves designed for this purpose.

- Tensioning: Adjust the tension of the drop wire according to specifications, ensuring it is aligned correctly without excessive sagging.

- Final Checks: Conduct a thorough inspection to ensure everything is secure and meets required standards.

Applications of Drop Wire Clamps

Drop wire clamps are widely used in various applications, including:

- Telecommunications: Used for securing fiber optic cables and coaxial cables in overhead installations.

- Electrical Distribution: Essential for attaching service drops from utility poles to residential or commercial buildings.

- Cable Television: Employed in securing cables that deliver television services from distribution points to homes.

Benefits of Using Drop Wire Clamps

- Enhanced Stability: Provides secure attachment points that reduce movement and sagging of cables.

- Signal Integrity: Minimizes interference and signal loss by maintaining proper tension on cables.

- Durability: Constructed from high-quality materials that withstand environmental conditions, ensuring long-term performance.

- Ease of Installation: Designed for quick and straightforward installation, reducing labor time and costs.

Selecting the Right Drop Wire Clamp

When choosing a drop wire clamp, consider several factors:

When choosing a drop wire clamp, consider several factors:

- Conductor Material and Size: Ensure compatibility with the specific type of conductor (e.g., copper or aluminum) and its size.

- Voltage Level: Higher voltage lines may require clamps with additional insulation or specific ratings for safety.

- Mechanical Strength: Evaluate whether the clamp can withstand tension loads without deformation or failure.

- Compliance Standards: Check that the clamp meets relevant industry standards for safety and performance.

Safety Precautions

When working with drop wire clamps, it’s essential to follow safety measures:

- Always wear appropriate personal protective equipment (PPE).

- Ensure that all tools are in good condition before use.

- Never work near energized lines without proper training and precautions.

- Follow manufacturer instructions for installation and handling.

A Leading Manufacturer

As a leading manufacturer of drop wire clamps, we focus on producing reliable components designed for the specific demands of telecommunications and electrical installations. Our clamps are constructed from high-strength materials such as galvanized steel and durable polymers, ensuring they withstand harsh environmental conditions while providing secure support for various cable types.

We prioritize precision in our manufacturing processes, with each clamp undergoing stringent quality checks to ensure optimal performance and compliance with industry standards. Our commitment to quality ensures that our products enhance the stability and longevity of your wiring systems.