Aluminum Support for ADSS

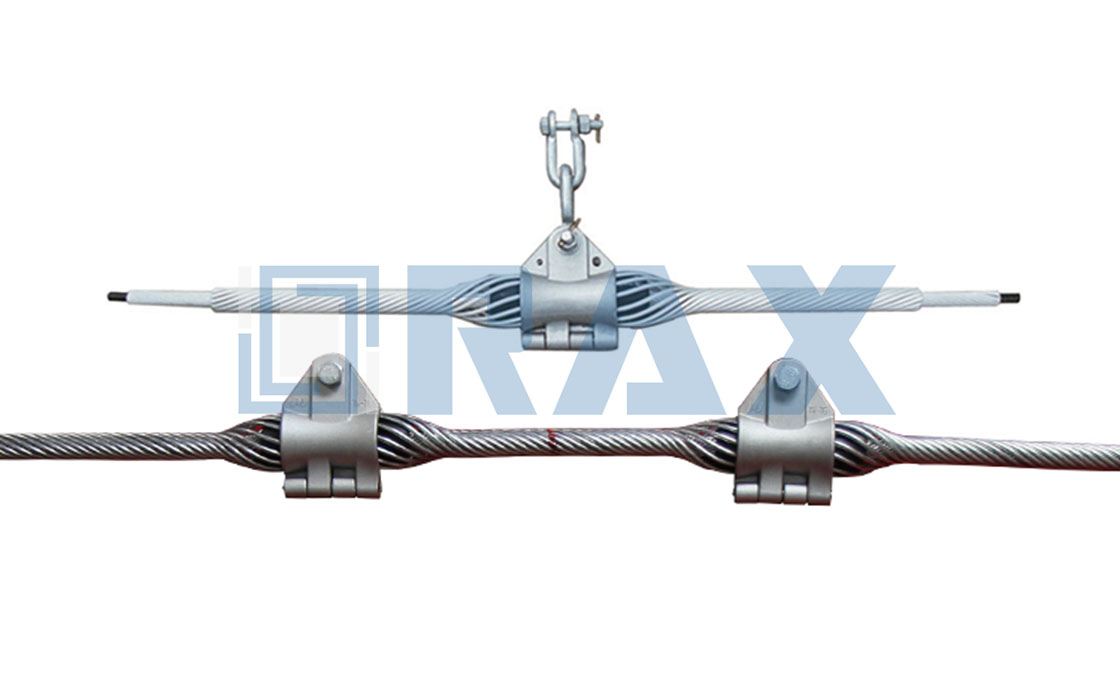

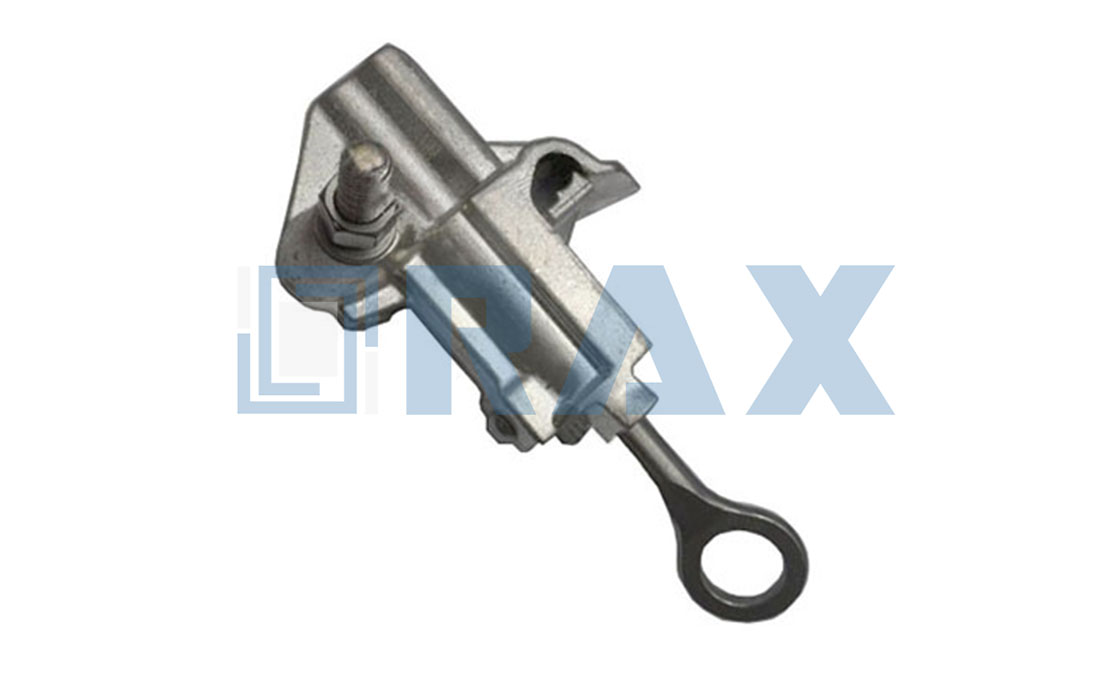

The Aluminum Support (FAS) is a support hardware used in fiber optic cable installations to support and secure All-Dielectric Self-Supporting (ADSS) cable. The FAS can be bolted to a structure or utility poles and helps to reduce installation costs by acting as a pull-through during aerial installations of fiber optic cables.

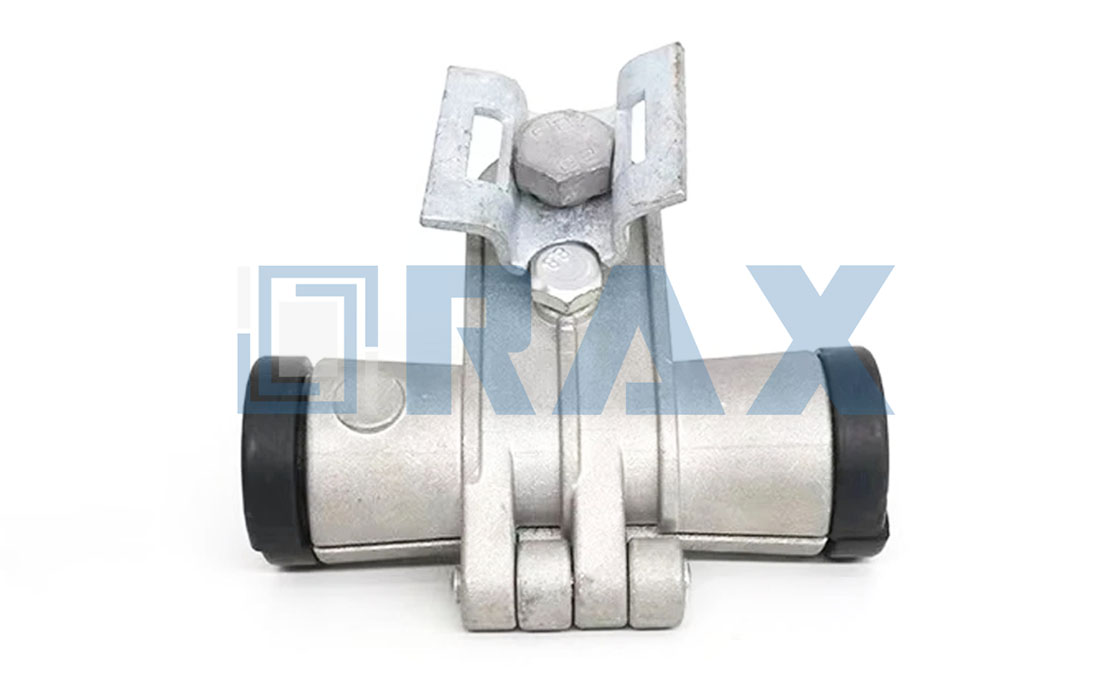

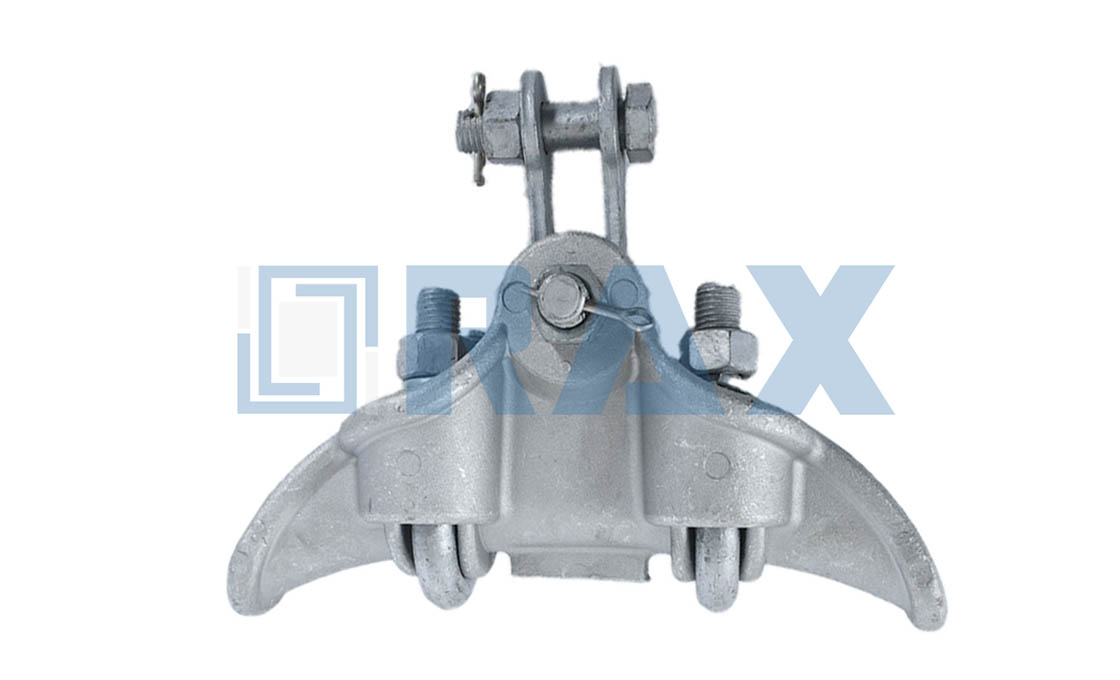

The Aluminum Support is designed with an integrated bolt or band mount, a base and keeper joined with an interlocking hinge that allows easy access to the cavity area for easy installation. It also features cushion inserts made from soft polyurethane which help in securing the cable without exerting excess pressure.

FAS is designed for use in installation of short span, low tension ADSS fiber optic cable installations where the vertical loading does not exceed 1000# (4.4 kN). It can also accommodate multi-cable installations as the base surfaces at the mounting bolt and band entry areas provide ample support for stacking.

Key Features:

- Casted from high strength aluminum

- The base and keeper are joined with an interlocking hinge for easy access for pulling-in rope and ADSS cable.

- Optimized for a broader combination of fiber counts and span lengths.

- No support or messenger wire required, so installation

- Features inserts made with soft pliable dielectric material to gently support the ADSS cable without causing damage.

- In stringing applications, the inserts can be removed and cable can rest loosely in housing

Type for Tower | Related cable outer diameter (mm) | ||

Min | Max | ||

FAS 1300-T | 9.0 | 13.0 | |

FAS 1700-T | 13.1 | 17.0 | |

Type for Pole | Related cable outer diameter (mm) | ||

Min | Max | ||

FAS 1300-G | 9.0 | 13.0 | |

FAS 1700-G | 13.1 | 17.0 | |

Frequently Asked Questions

How is the FAS mounted?

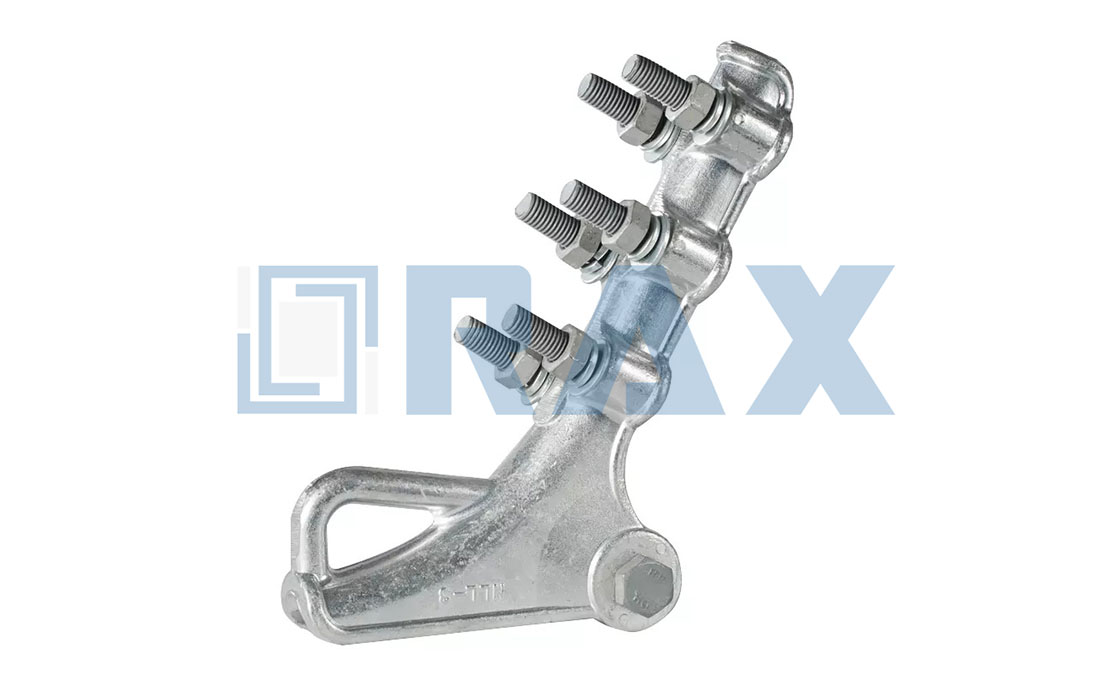

The FAS can be bolted or banded to different structures including wood poles, concrete or steel structures. For wood poles and other structures with through holes a 5/8″-11 (M16) through-bolt or double-arming bolt can be used to secure the FAS to the pole. For structures without through holes, the FAS can be banded to the structure via the band slot at the base of the FAS.

Can the FAS accommodate stacking?

Yes, multiple cable installations can be done using the FAS. The first unit typically mounts against the pole while the added units extend horizontally by securing them with a 5/8″ (M16) bolt. When the installation is for more than two cables, a brace should be used to support the cantilever load on the through bolt or band.

What is the maximum span length allowed?

The FAS is intended for use in installation of short span applications where the verting loading does not go beyond 1000# (4.4 kN). The maximum vertical load capacity will depend on the span length, cable OD, initial cable tension, ice and wind loading district, among other factors. The recommended span lengths under NESC Heavy conditions are:

- 600′ (183 m) for < 1.00″ (25 mm) OD cable (NESC Heavy)

- 300′ (91 m) for > 1.00″ (25 mm) OD cable (NESC Heavy)

What are the recommended line angles when mounting?

For most applications, the maximum line angle recommended is 20°. There are some exceptions that allow for 30° angles. When angles exceed 20° (or 30°), the Aluminum Suspension may be used as an alternative.