Glass Suspension Insulator

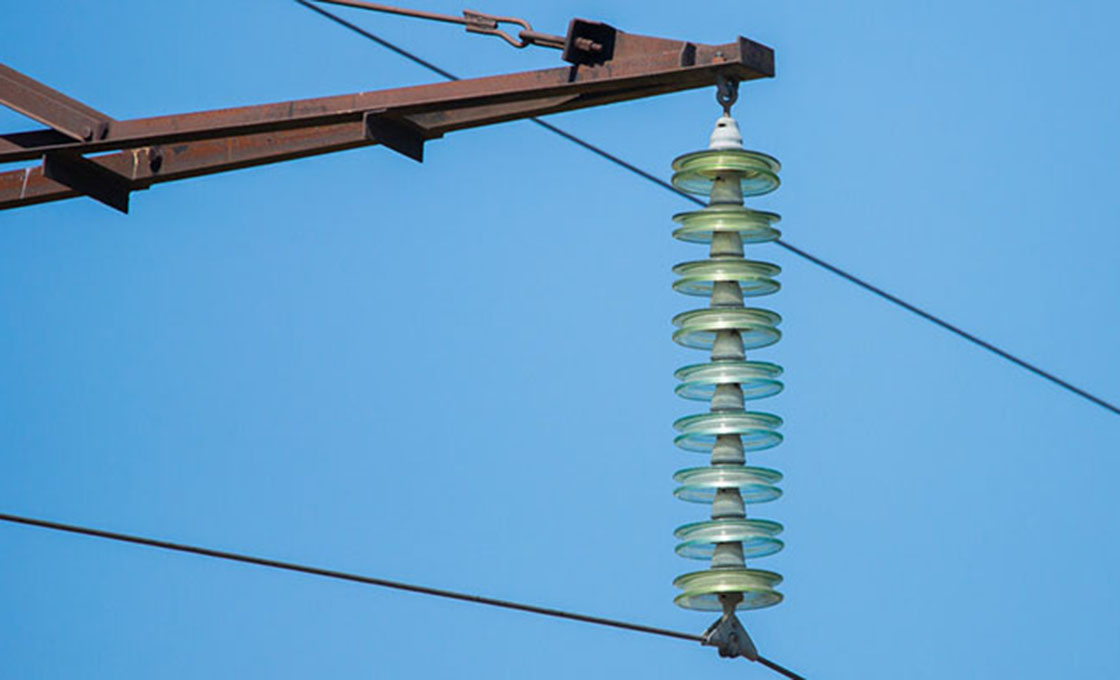

Glass Suspension Insulators, also known as suspension glass insulators or disc insulators, are essential components used for isolating and fixing wires to overhead power lines, power distribution facilities, and substations. These insulators consist of three main components: an insulating glass disc, metal fittings (cap and pin) at each end, and cement bonding material. The glass disc features specially designed sheds and ribs that provide additional leakage paths for surface water and contaminants. They are available in standard profile (low height ribs with large spaces) and fog-type profile configurations.

Glass Suspension Insulators are designed to operate in AC voltage systems over 1000V with frequencies up to 100 Hz, functioning in ambient temperatures from -60 to +50°C. The installation involves assembling multiple glass suspension insulators into vertical strings, with the number of units determined by the system voltage requirements. These insulators work with various overhead conductors, transmission towers, and substation structures, providing both electrical isolation and mechanical support while maintaining proper conductor spacing and tension.

Key Features:

- Self-cleaning design allows natural cleaning by rain or wind

- High dielectric strength with superior insulation properties

- Toughened glass construction ensures mechanical strength and thermal stability

- Visual failure detection through glass shattering

- Multiple coupling options including ball-and-socket and tongue-and-clevis designs

- Suitable for both light and medium polluted environments

glass disc insulator

| Universal Model | U160B/170 | U160B/155 | U160B/146 |

| ( mm ) Diameter | 280 | 280 | 280 |

| ( mm ) Height | 170 | 155 | 146 |

| ( mm )Leakage distance | 400 | 400 | 400 |

| ( mm )Coupling | 20 | 20 | 20 |

| ( kN ) SML | 160 | 160 | 160 |

| ( kN )Tension Load Test | 80 | 80 | 80 |

| ( kV )Power frequency Withstand wet | 45 | 45 | 45 |

| ( kV )Lightning Impulse Withstand | 110 | 110 | 110 |

| ( P.U )Puncture Impulse Voltage | 2.8 | 2.8 | 2.8 |

| ( kV )Puncture power frequency voltage | 130 | 130 | 130 |

Glass suspension insulator details and parameters

Frequently Asked Questions

What are the main components of a glass suspension insulator?

What are the main components of a glass suspension insulator?

The insulator consists of an insulating glass disc, metal fittings (cap and pin) at each end, and cement bonding material. Each disc features specially designed sheds and ribs for water drainage. Metal fittings provide attachment points for supporting structures.

What are the operating specifications?

Designed for AC voltage systems over 1000V with frequencies up to 100 Hz, operating in temperatures from -60 to +50°C. Available in standard profile (low height ribs) and fog-type profile configurations for different pollution levels.

What are the testing requirements for quality assurance?

Testing includes steep-front puncture tests, RIV testing for pin cavity design, ultimate tensile testing, residual mechanical strength verification, and thermal shock testing to check glass shell quality.

How are glass suspension insulators installed?

Installation requires proper spacing (one per 3.5 ft² of wall area), with specific horizontal and vertical spacing requirements. Multiple units are assembled into vertical strings, with quantity determined by system voltage requirements.

What maintenance is required?

Regular inspection of metal fittings and exposed components is necessary. The self-cleaning design allows natural cleaning by rain or wind. Visual inspection can easily detect defects due to glass transparency.

What are the environmental performance characteristics?

Suitable for industrial, agricultural, and coastal areas. Fog-type profiles prevent partial discharges between contiguous standouts in heavy pollution. The hydrophobic coating repels water droplets in wet conditions.

What are the mechanical specifications?

Load capacities vary by model, ranging from 40kN to 160kN minimum mechanical failing load. Spacing heights range from 110mm to 170mm, with creepage distances from 185mm to 460mm depending on the model.

What advantages do glass insulators offer?

They provide high mechanical strength, superior surface resistance to cracking, slow aging, and easy defect detection. No periodic live testing is required, reducing maintenance costs. Visual failure detection is possible through glass shattering.

What are the main components of a glass suspension insulator?

What are the main components of a glass suspension insulator?