Are you searching for a reliable anchoring solution for challenging soil conditions? Arrowhead earth anchors offer exceptional holding power and versatility, making them an ideal choice for various construction and stabilization projects. This comprehensive guide will help you understand everything about these powerful anchoring devices.

Table of Contents

- 1 What Makes Arrowhead Earth Anchors Different?

- 2 How Do Arrowhead Anchors Actually Work?

- 3 Arrowhead Anchors VS Duckbill Anchors

- 4 Which Soil Types Work Best with Arrowhead Anchors?

- 5 What Installation Methods Ensure Maximum Performance?

- 6 What Applications Best Suit Arrowhead Anchors?

- 7 How Do You Calculate Required Anchor Strength?

- 8 What Maintenance Ensures Long-Term Performance?

- 9 What Are The Cost Considerations?

- 10 Frequently Asked Questions

- 11 Custom Your Arrowhead Anchors

What Makes Arrowhead Earth Anchors Different?

Arrowhead earth anchors represent a significant advancement in ground anchoring technology. Unlike traditional anchors that rely solely on mass or surface area, these innovative devices utilize mechanical advantage and soil compression to achieve remarkable holding power.

The anchor consists of three main components working in harmony:

- A specially designed arrowhead-shaped tip made from heat-treated 256 T6 aluminum or malleable iron

- A high-strength galvanized steel aircraft cable with thimble end

- A locking mechanism that ensures one-way installation

The genius of the design lies in its toggle action. When initially driven into the ground, the arrowhead maintains a straight position. Once installed, applying tension causes the head to rotate perpendicular to the pull direction, effectively creating a underground toggle bolt that engages a much larger soil area than traditional anchors.

Advanced Engineering Features

- Precision-engineered pivot points for consistent rotation

- Reinforced cable attachment points

- Corrosion-resistant materials throughout

- Load-distributed design for maximum soil engagement

How Do Arrowhead Anchors Actually Work?

Understanding the mechanical principles behind arrowhead anchors helps appreciate their effectiveness. The installation and engagement process occurs in three distinct phases:

Phase 1: Installation During the initial drive, the anchor maintains a streamlined profile, allowing for easier soil penetration. The arrowhead’s sharp edges cut through the soil while maintaining a straight path along the drive rod.

Phase 2: Rotation Once the desired depth is reached and the drive rod is removed, the first pull on the cable triggers the anchor’s rotation. This crucial movement transforms the anchor from a vertical position to a horizontal one, maximizing its resistance against pullout forces.

Phase 3: Engagement The rotated anchor now engages with undisturbed soil above it, creating a cone of resistance that grows larger as more force is applied. This mechanical advantage explains why arrowhead anchors can achieve such impressive holding power despite their relatively small size.

“The key to an arrowhead anchor’s superior performance lies in its ability to engage undisturbed soil above the installation point, creating a resistance cone that increases in strength with applied load.”

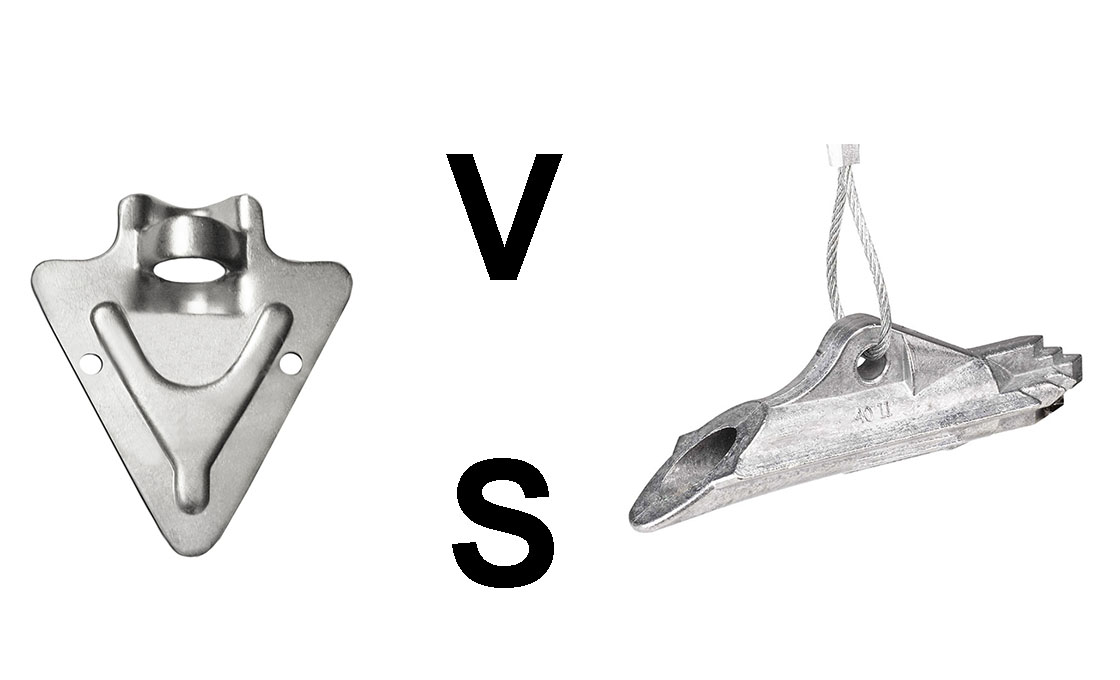

Arrowhead Anchors VS Duckbill Anchors

Duckbill anchors are innovative ground anchoring devices that work like toggle bolts in soil. They feature a unique design that requires no holes or digging, creating minimal soil disturbance during installation. When pulled upward, the anchor tendon rotates the Duckbill into a perpendicular “anchor lock” position in undisturbed soil, providing superior holding capacity.

Design and Construction

- Arrowhead: Features a pointed arrowhead-shaped tip with aircraft cable

- Duckbill: Manufactured from aluminum alloys or galvanized ductile iron for hard rocky soils

Installation Method

- Arrowhead: Requires pre-drilling in some conditions

- Duckbill: Driven directly into ground with a reusable drive steel, no holes or digging needed

Performance Characteristics

| Feature | Arrowhead | Duckbill |

|---|---|---|

| Installation | More complex | Three simple steps |

| Soil Compatibility | Better in rocky soil | Works in total range of soils |

| Holding Capacity | Up to 9,000 lbs | 300 to 5,000 lbs |

| Environmental Impact | Moderate | Minimal soil disturbance |

Testing and Verification

- Arrowhead: Requires settling time

- Duckbill: Can be immediately load tested after installation

“Both anchor types offer reliable solutions, but Duckbill’s minimal soil disturbance and quick installation make it particularly suitable for environmentally sensitive applications.”

Which Soil Types Work Best with Arrowhead Anchors?

Soil composition plays a crucial role in anchor performance. Let’s explore how different soil types affect holding capacity and installation requirements:

Soil Performance Analysis

| Soil Type | Holding Capacity | Installation Notes | Best Applications |

|---|---|---|---|

| Hardpan | Maximum (up to 9,000 lbs) | Pre-drilling recommended | Permanent structures |

| Dense Gravel | 7,000-8,000 lbs | Direct drive possible | Heavy-duty anchoring |

| Medium Sandy Gravel | 5,000-6,000 lbs | Standard installation | Temporary structures |

| Loose Sand | 3,000-4,000 lbs | Deeper installation needed | Light-duty applications |

Understanding these soil characteristics helps in:

- Selecting appropriate anchor size

- Determining installation depth

- Choosing the right installation method

- Estimating holding capacity

This comprehensive understanding of soil interaction ensures optimal anchor performance across various applications and conditions.

What Installation Methods Ensure Maximum Performance?

Proper installation is crucial for achieving optimal holding power with arrowhead anchors. The method you choose can significantly impact the anchor’s performance and longevity.

Professional Installation Equipment Modern installation methods have evolved to provide efficient and reliable results. Here’s a detailed breakdown of available options:

- Hydraulic Drivers

- Best for large-scale projects

- Provides consistent driving force

- Reduces installer fatigue

- Ideal for 6-inch and larger anchors

- Offers precise depth control

- Manual Installation Tools

- Suitable for smaller anchors (2-4 inch)

- Requires drive rod and sledgehammer

- More economical for occasional use

- Allows for better feel in difficult soils

- Perfect for remote locations

Installation Steps for Maximum Effectiveness

- Site Preparation

- Mark underground utilities

- Clear vegetation

- Assess soil conditions

- Determine proper installation angle

- Anchor Positioning

- Set anchor perpendicular to expected load

- Maintain minimum distance from structures

- Consider multiple anchor patterns for heavy loads

What Applications Best Suit Arrowhead Anchors?

Arrowhead anchors demonstrate remarkable versatility across numerous applications. Understanding these applications helps select the right anchor for your specific needs.

Construction Applications These anchors excel in various construction scenarios:

- Temporary bracing for concrete forms

- Guy-wire supports for tall structures

- Retaining wall tie-backs

- Foundation stabilization

- Scaffold securing

Recreational and Residential Uses The versatility extends to lighter-duty applications:

- Tree support systems

- Playground equipment anchoring

- Garden structure stabilization

- Tent and canopy securing

- Sports field equipment mounting

Special Application Considerations Each application requires specific attention to:

- Load direction and magnitude

- Soil conditions at installation site

- Environmental factors

- Access for installation equipment

- Long-term maintenance requirements

“Success in specialized applications often depends on proper planning and understanding of site-specific conditions. Always consider both immediate and long-term loading requirements when selecting anchor size and installation method.”

How Do You Calculate Required Anchor Strength?

Understanding load requirements is essential for selecting the right arrowhead anchor. This calculation process ensures both safety and cost-effectiveness in your anchoring solution.

Load Calculation Factors Several critical elements influence the required anchor strength:

| Factor | Consideration | Safety Multiplier |

|---|---|---|

| Direct Load | Actual weight/force | 1.5x |

| Wind Load | Geographic location | 2.0x |

| Soil Type | Ground conditions | 1.3-2.0x |

| Load Angle | Pull direction | 1.2-1.8x |

Working Load Formula The basic calculation follows this principle: $$ Required\;Strength = Base\;Load × Safety\;Factor × Soil\;Factor × Angle\;Factor $$

What Maintenance Ensures Long-Term Performance?

Proper maintenance significantly extends the life and reliability of arrowhead anchors. Here’s a comprehensive approach to maintaining your anchoring system.

Regular Inspection Schedule

- Monthly visual checks of exposed components

- Quarterly tension verification

- Annual thorough system inspection

- Post-extreme weather evaluation

Common Issues and Solutions Understanding potential problems helps prevent failures:

- Cable fraying: Requires immediate replacement

- Soil erosion: May need additional anchoring

- Tension loss: Adjust and monitor regularly

- Surface rust: Apply protective coating

What Are The Cost Considerations?

Making an informed decision about arrowhead anchors requires understanding the total cost of ownership.

Initial Investment Factors

- Anchor size and material quality

- Quantity needed for project

- Installation equipment requirements

- Professional installation services

Long-term Value Analysis Consider these aspects when evaluating cost-effectiveness:

- Expected service life: 15-25 years

- Maintenance requirements

- Replacement costs

- Performance reliability

- Installation efficiency

“While initial costs may seem higher than simpler anchoring solutions, the long-term reliability and reduced maintenance needs often make arrowhead anchors more economical over their lifetime.”

Frequently Asked Questions

What is an Arrowhead Earth Anchor?

An anchoring system shaped like an arrowhead, constructed with durable ductile iron or heat-treated aluminum. It’s designed for securing structures in challenging soil conditions, particularly excelling in hard, compact, and rocky soils.

.What is the pull-out resistance capacity?

- Small (2-inch) models: Up to 600 lbs in hardpan soils

- Larger models: Up to 4,200 lbs in certain soil types

- Varies based on soil conditions and installation depth

How are Arrowhead Anchors installed?

Installation involves three simple steps:

- Drive the anchor into the ground using a reusable drive rod and hammer

- Remove the drive rod

- Pull the cable to “set” or “key” the anchor into position

What are the minimum installation depths?

- 2-inch or 4-inch arrowhead anchors: 3 feet minimum

- Larger anchors: 5 feet minimum

What applications are they suitable for?

- Erosion control/matting

- Securing fencing

- Underwater pens

- Theft deterrence

- Weather security

- Anchoring swings and playground equipment

- Guying trees

- Solar tower securing

What soil types work best?

- Hardpan: Optimal performance

- Dense gravel (Class 1): Excellent holding power

- Medium-dense sandy gravel (Class 2): Good performance

- Loose to medium dense sand (Class 3-4): Moderate performance

What materials and components are used?

- Anchor head: Ductile iron or heat-treated aluminum

- Cable: Galvanized 7×19 steel aircraft cable

- Cable strength: 2000lb minimum breaking strength

- Available with various terminations: Thimble loops, cable clamps, Quickvise

Custom Your Arrowhead Anchors

At RAX Industry, we specialize in manufacturing series Earth Anchors for your projects. Our anchors undergo rigorous quality control, including torque, pull-out, and corrosion tests, to ensure reliable performance across a variety of applications. We offer multiple customization options, including different sizes, mounting choices, and custom cable lengths.

We provide comprehensive services, including engineering assistance to help you select the right anchor for your needs. With worldwide shipping capabilities and flexible ordering options, we ensure your satisfaction. Our Arrowhead Earth Anchors offer up to 600 lbs of pull-out resistance in hard-pan soil and come with a range of accessories for diverse installation requirements, making them ideal for everything from fencing to playground equipment security.