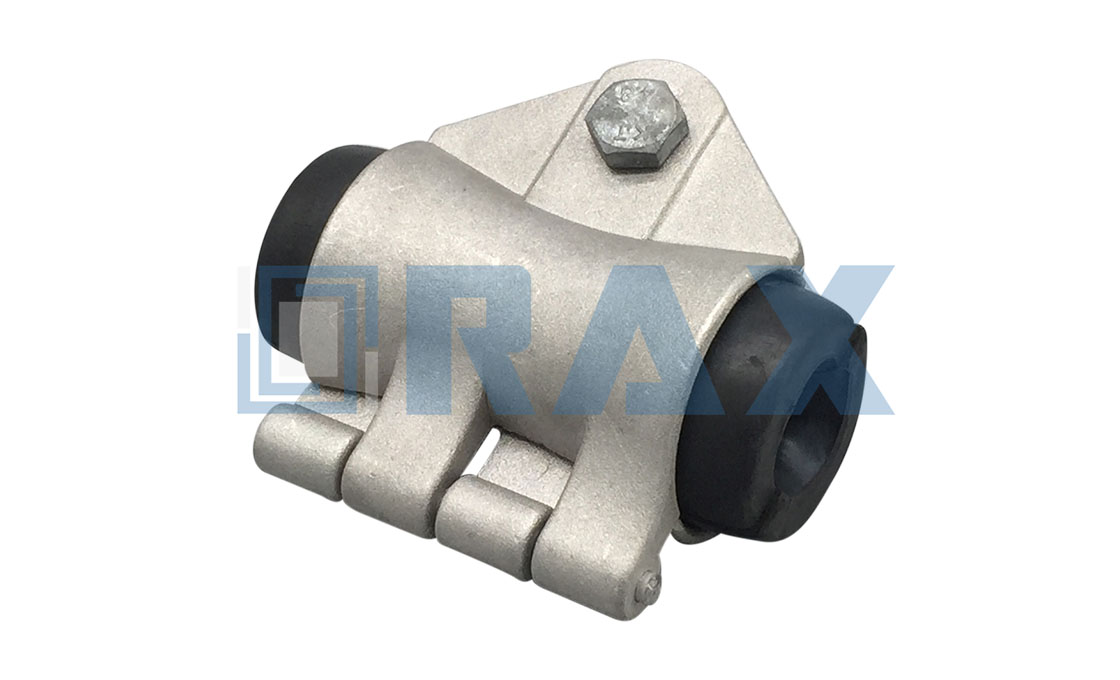

Split Bolt Connector

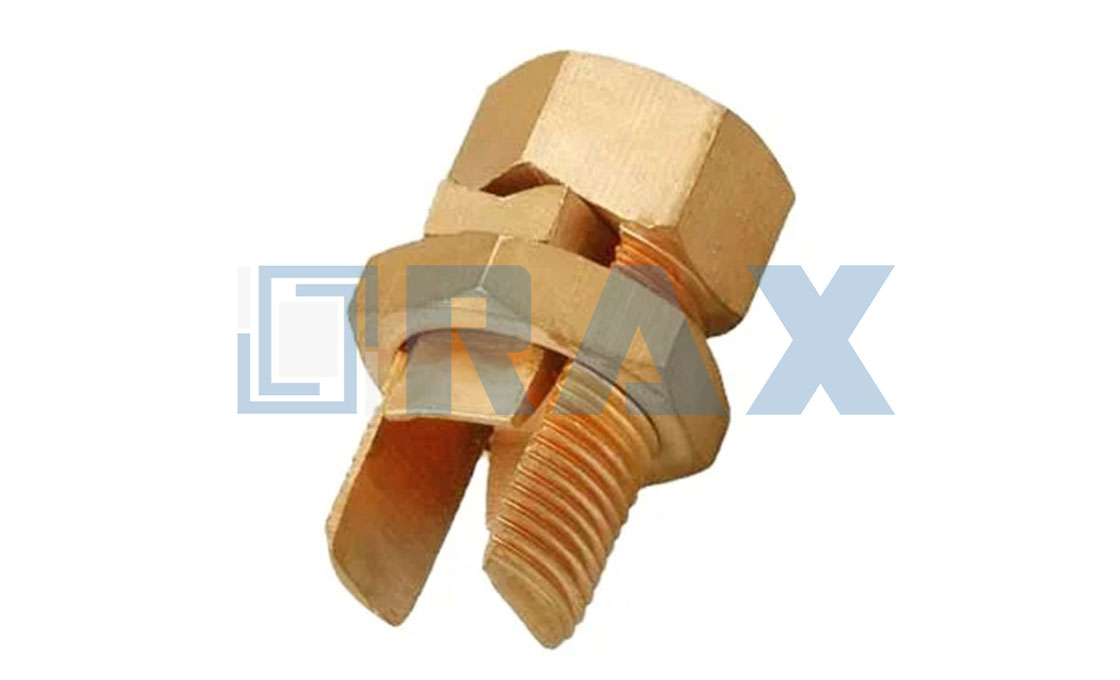

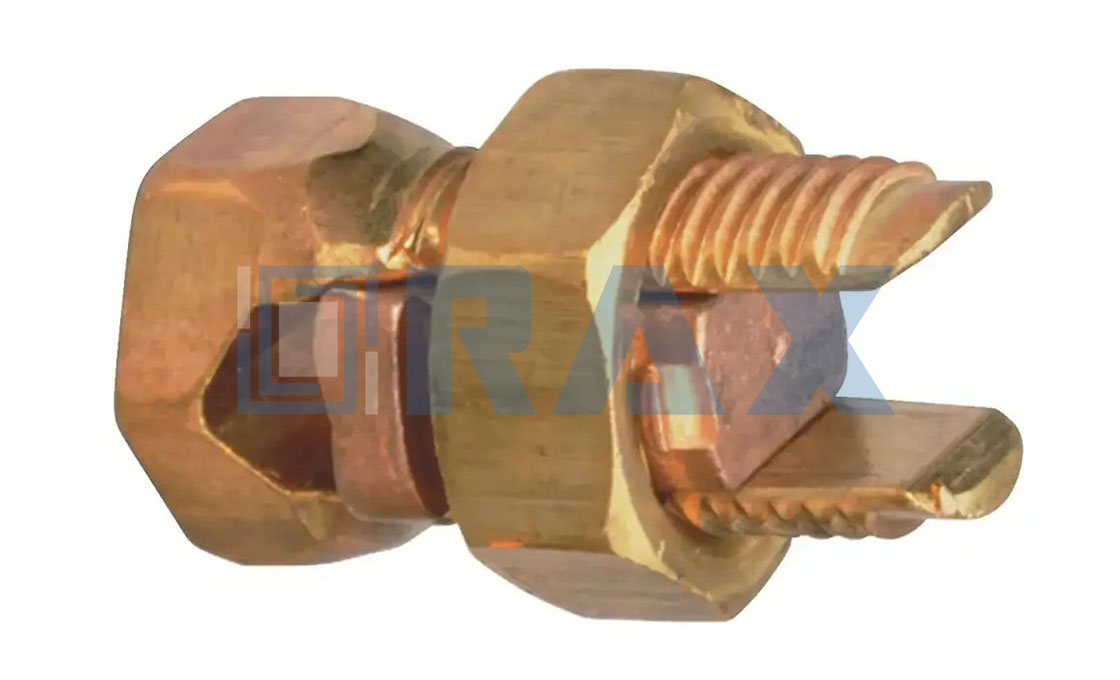

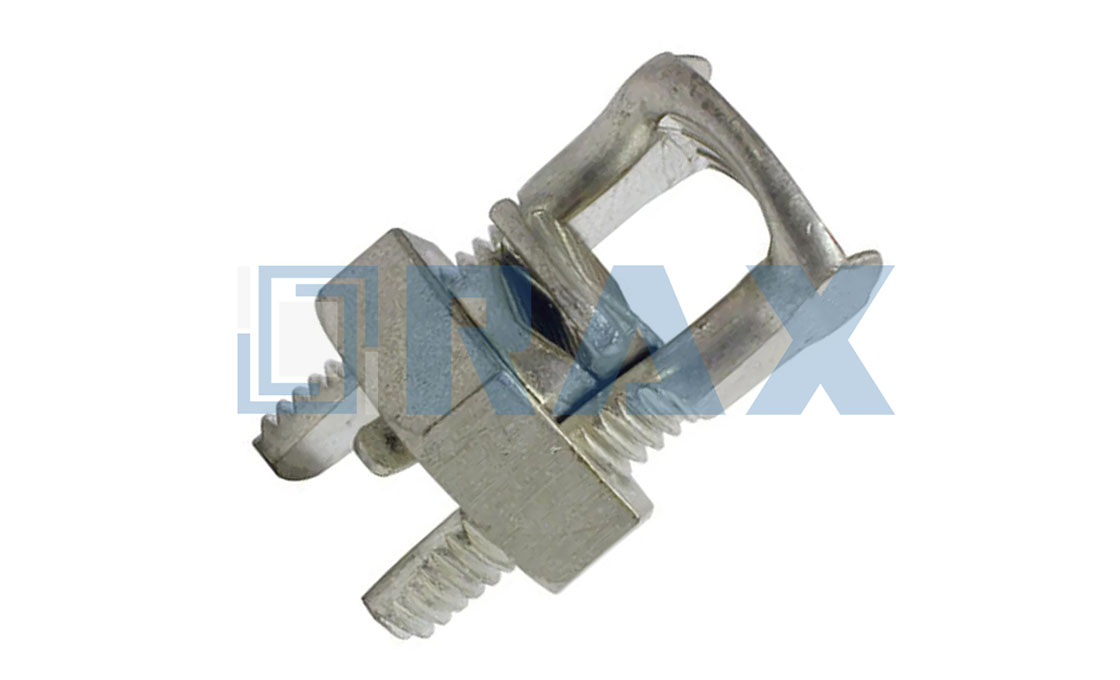

Split bolt connectors from Rax Industry are used to connect two or more wires together to facilitate the transmission of electricity. They are stronger and more reliable than other types of electrical connectors, making them ideal for applications where there are high voltages such as grounding applications.

The main function of a split bolt connector is to join two or more copper or aluminum wires, creating a stable and low-resistance electrical connection.

The structure of the connector features a bolt with a split in the middle that allows the connector to open up so that the wires can be inserted. When the connector joins the copper or aluminum wires, it creates a complete circuit that allows electricity to flow.

The split bolt connector is popular amongst electricians because of its reliability and ease of installation. It is commonly used as an alternative to the traditional splicing of twisted wires since it is safer and creates a durable connection.

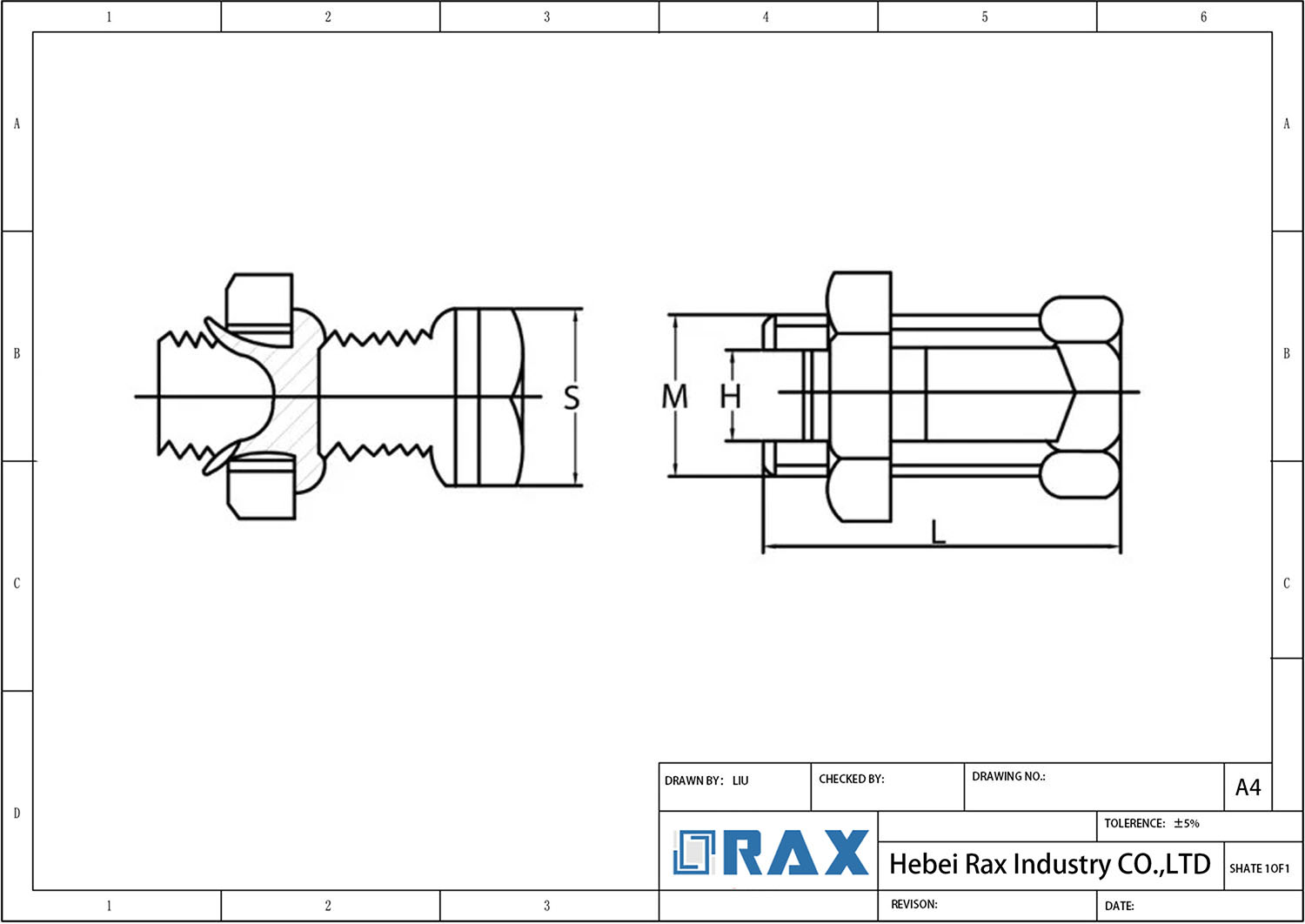

Split Bolt Connector Drawing

Item No. | L | M | H | S |

| SBC-16 | 20 | M17×2.5 | 6 | 18 |

| SBC-25 | 27 | M19×2.5 | 7 | 20 |

| SBC-35 | 35 | M21×2.5 | 7 | 22 |

| SBC-50-70 | 42 | M23×2.5 | 11 | 24 |

| SBC-90-120 | 45 | M25×2.5 | 14 | 26 |

| SBC-150-185 | 60 | M29×2.5 | 17 | 30 |

| SBC-200-240 | 72 | M31×2.5 | 20 | 32 |

Frequently Asked Questions

How to Choose Split Bolt Connectors

How to Choose Split Bolt Connectors

Material:

Split bolt connectors are typically made of conductive materials such as copper, aluminum, bronze, or alloys. The type of connector you choose will depend on the specific application and preference.

For instance, copper connectors are highly conductive and durable so they are very popular. However, connectors made of aluminum tend to be more cost-effective so they may appeal to those on a budget.

Size:

Split bolt connectors are available in different sizes. The appropriate connector size will depend on the size of the wires to be connected. The wires should be able to fit snugly within the connector to ensure a reliable connection.

A connector that is too large will leave gaps while one that is too large will lead to overfilling, both of which can interfere with efficient transfer of electrical current.

How to Install a Split Bolt Connector

- Start by stripping the insulation covering to expose the ends of the conductive copper to be connected.

- Once the ends of the wire are stripped, insert the ends of the two wires to be joined into the split in the middle of the shank of the bolt.

- Once the wires are securely in place, tighten the nut at the bottom of the connector. No special tools are required, the bolt can be tightened with a wrench. A tight connection is important to prevent the wires from coming loose with time and to establish a reliable electrical connection.

- During installation, check and adhere to any manufacturer’s guidelines and precautions.

- Once the connector has been secured into place, check that the connection is properly insulated to avoid damage from water, corrosion, and other contaminants.

Advantages of a Split Bolt Connector

- Creates a low-resistance electrical connection.

- Safer and more reliable compared to other types of connectors such as crimp connectors.

- It helps to minimize loss of energy, ensuring efficient transfer of electricity.

- Boasts a high voltage capacity so it is ideal for high-power systems and applications such as grounding.

- Available in different sizes to suit different sizes of copper or aluminum wire.

- No special tools are required for installation.

How to Choose Split Bolt Connectors

How to Choose Split Bolt Connectors