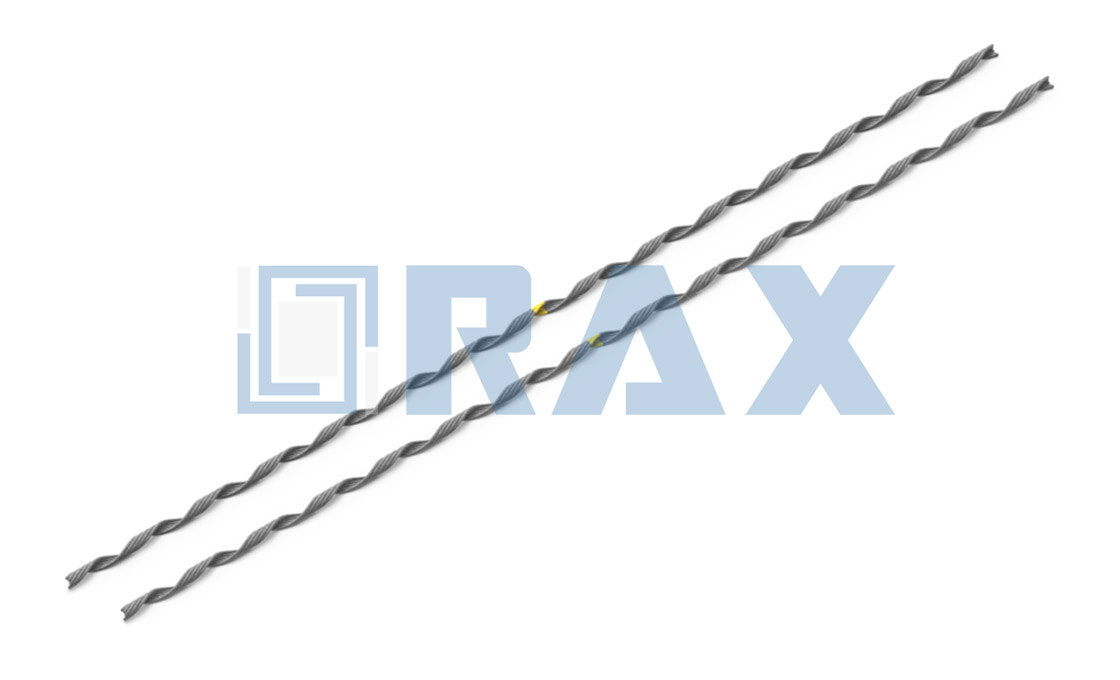

Strand Splice

Strand Splice is also called Strand Splice. Splice connectors are designed to repair damaged guy wire or messenger cable by connecting multiple sections. Splices offer a cost-effective solution for repairing damaged cables or guy wire, providing excellent load bearing capacity and long term reliability.

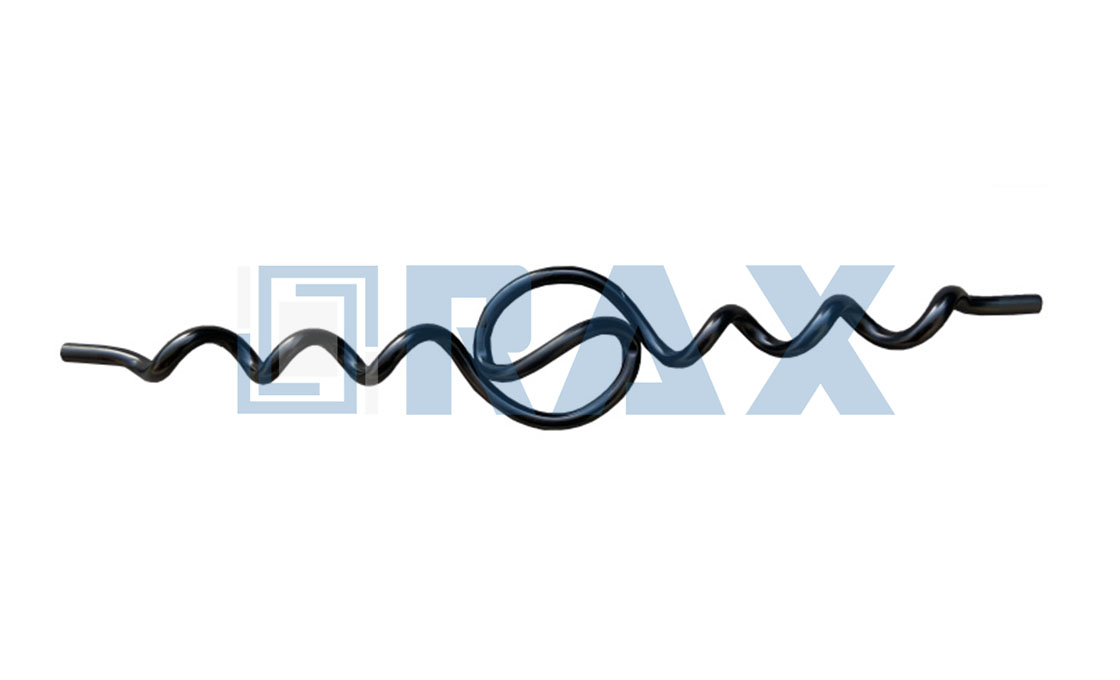

There are different types of automatic and compression splice connectors designed to suit various applications. Compression splices can be full tension, minimum tension, or partial tension. They also come in nylon insulated varieties and as repair sleeves.

Automatic splicers are available in different materials. It is important to ensure that splice connectors used in repairs are of the same basic material as the cable they are applied to. This ensures that the holding strength of the splice connector is equivalent to the rated breaking strength of the strand.

The function of the splice connectors is to ensure that when the splice is centered over the point of damage on the guy wire or messenger cable, the full rated breaking strength of the strand is restored.

Preformed splice connectors come in different sizes to suit different applications. For precision and safety, it is important to select the appropriate size to ensure tight assembly.

Key Features

- Rated for 100% of the strands published rated breaking strength unless otherwise noted.

- Made of the same basic material as the strand to which they are applied.

- Available in different materials including galvanized steel, aluminium, copper and stainless steel

- Superior design for maximum strength and excellent fatigue characteristics for durability

| Series | Strand | | Units | Wt./Lbs. | Length (In.) | No. of Subsets | Rod Diameter (In.) | ||

| Size (In.) | Construction | Actual Diameter (In.) | Per C | arton | ||||

| SS3/16 | 3/16 | 7W 7W | .195 .186 | 100 | 30 | 27 | 2 | .070 |

| SS7/32 | 7/32 | 7W | .216 | 100 | 36 | 29 | 2 | .070 |

| SS1/4 | 1/4 | 3W 7W | .259 .240 | 50 | 34 | 35 | 2 | .086 |

| SS9/32 | 9/32 | 7W | .279 | 50 | 36 | 38 | 2 | .086 |

| SS5/16 | 5/16 | 3W 7W | .312 .327 | 50 | 46 | 42 | 3 | .086 |

| SS3/8 | 3/8 | 3W 7W | .356 .360 | 25 | 38 | 50 | 3 | .100 |

| SS7/16 | 7/16 | 7W | .435 | 25 | 58 | 56 | 3 | .119 |

| SS1/2 | 1/2 | 7W 19W | .495 .500 | 10 | 36 | 63 | 3 | .138 |

| SS9/16 | 9/16 | 7W 19W | .564 .565 | 10 | 52 | 70 | 4 | .159 |

Frequency Asked Questions

What are preformed splices used for?

Splices are used to connect or repair severed or damaged sections of guy wire or cable seamlessly while maintaining signal continuity and retaining the holding strength of the intact cable. They are a cost-effective alternative to replacing entire cable in case of damage.

Can preformed splice connectors be reused?

Strand splices are intended for one time use and should not be re-used after the original application to the strand.

What material are preformed splices made of?

Splices are made from high tensile strength and durable materials such as galvanized steel, stainless steel, aluminium, or copper. In any application, the type of splice selected should be made of the same material as the strand or cable to which it is being applied. This is to ensure that the full rated strength of the strand is restored after repair.

How are splices installed?

Preformed splices should always be installed by qualified personnel to prevent distortion or damage. It is important to use the right splice connector size to ensure tight assembly, safety and long-term durability. Extra safety precautions should always be taken when working with energized cables to prevent injury.

What accessories are used with splices?

Depending on the application and type of preformed splice being used accessories such as welding equipment, crimping tools, coatings, bonding agents, and insulating materials be required. Testing devices may also be used after the installation process to check the quality and performance of the splice.