Pole Top Bracket

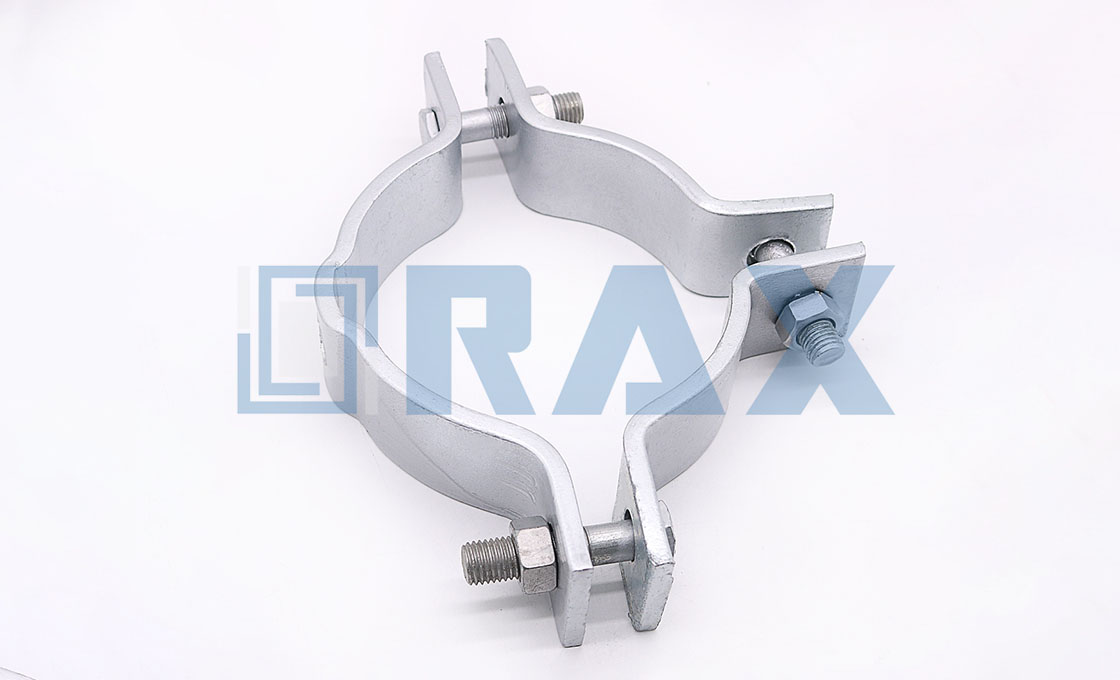

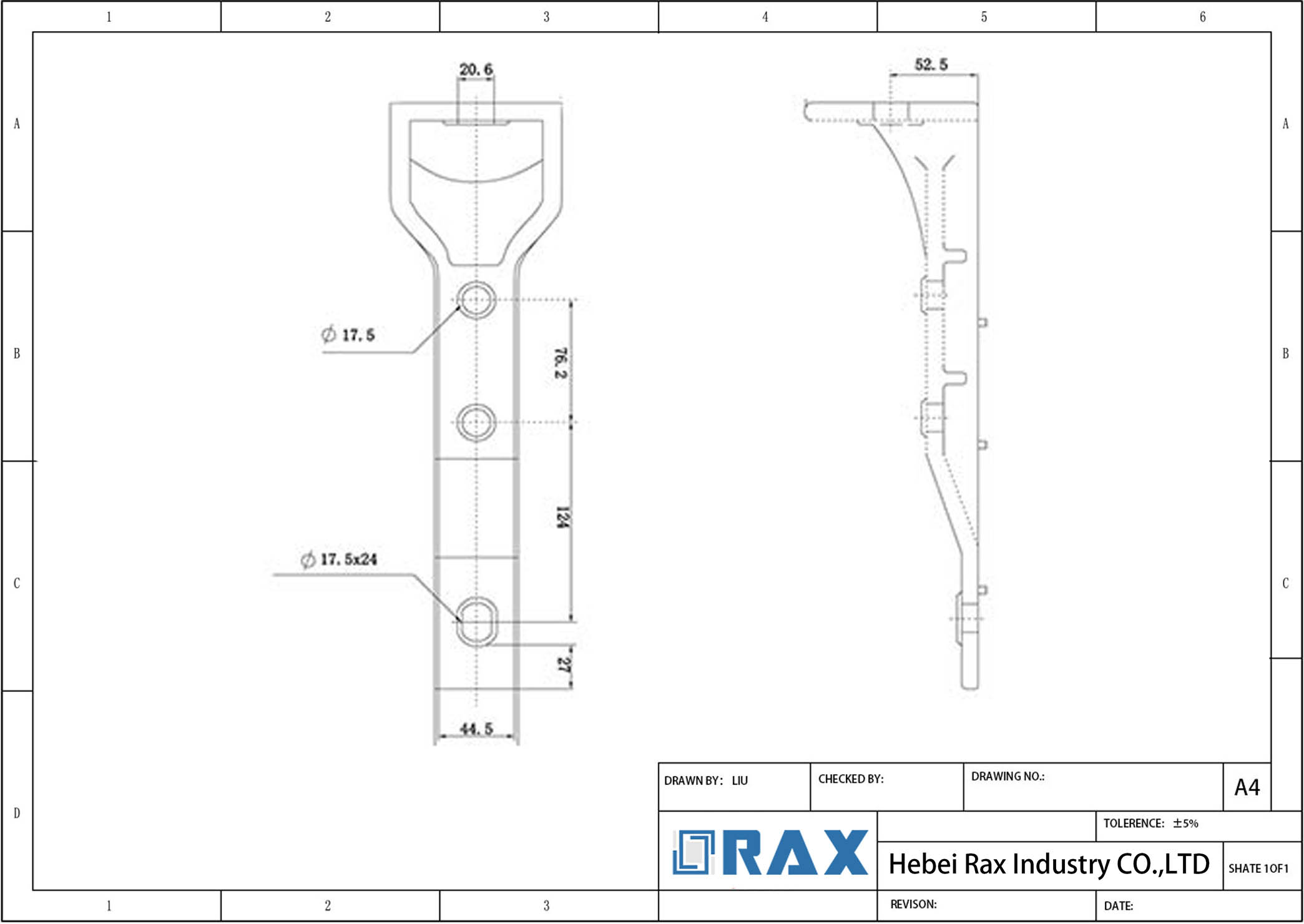

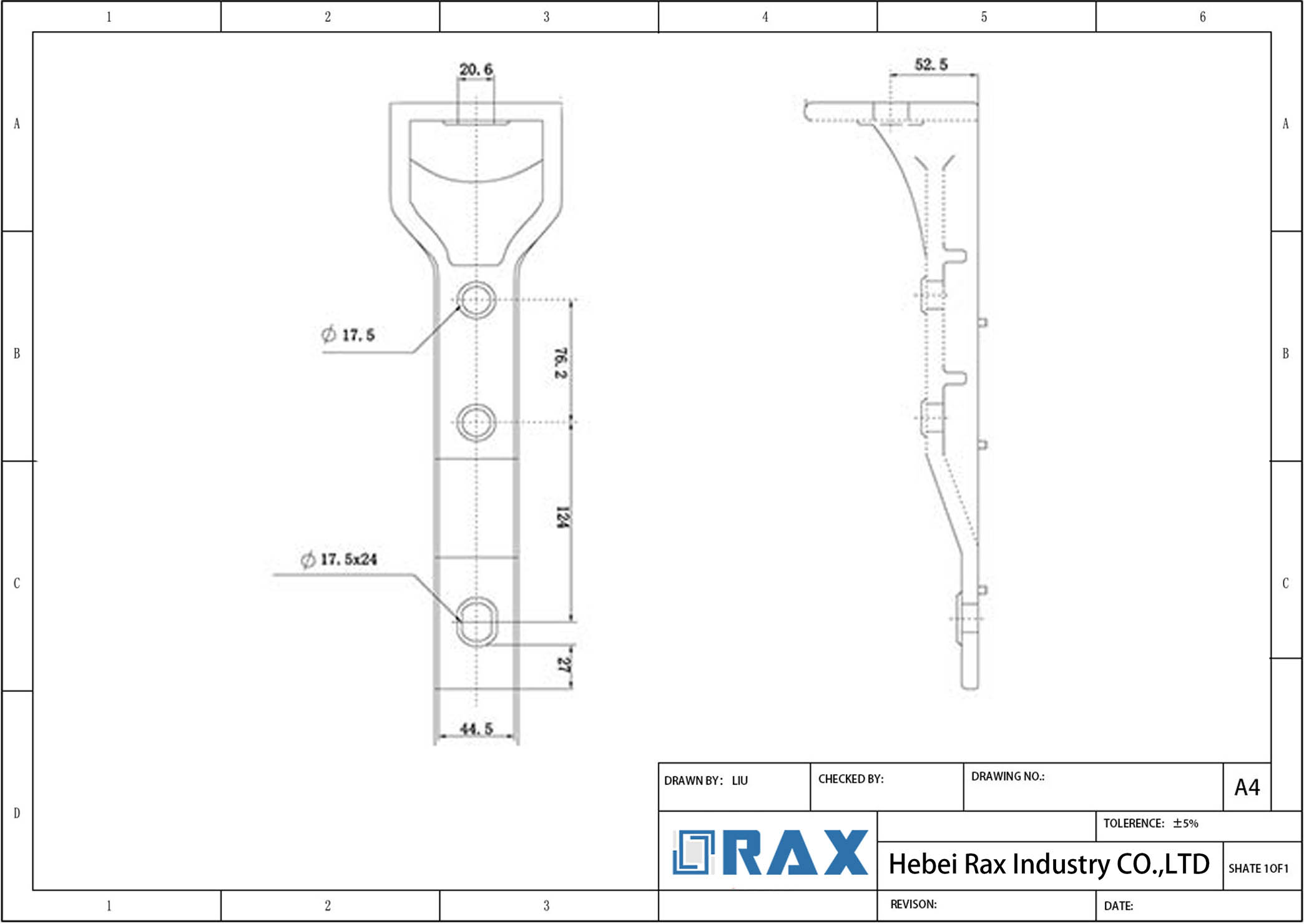

The pole top bracket is installed against flat pole gains. Rax Industry pole top bracket is designed to mount post type insulators by means of a single 19mm (3/4) diameter stud bolt. Mounting surfaces of brackets contain a non-tap hole of 20.5mm in diameter post insulators to be mounted on these pole top brackets.

The Pole top bracket is made to permit mounting on wood poles by two 16mm diameter bolts vertically spaced 203mm center to center. One of the bracket mounting holes is slotted to permit slight variations in mounting bolt spacing. The insulator mounting surface is at a height approximately 125mm above the top bracket mounting hole.

The pole top bracket needs to have strong and durable foundations to provide support even during storms and disasters. So it’s important to find a good pole top bracket manufacturer and supplier. Rax Industry has worked on producing the pole top bracket since 1999 and is ready to solve your problems and reduce your cost.

Rax Industry Pole top bracket has the following features:

1. Hot dip galvanized according to ISO1461

2. Tension Strength up to 70kn

3. Size accurate 0.2mm

4. Raw materials are new without recycling

5. Factory price saves your cost 30-50%

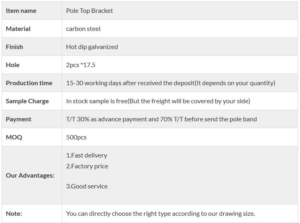

| Item name | Pole Top Bracket |

| Material | carbon steel |

| Finish | Hot dip galvanized |

| Hole | 2pcs *17.5 |

| Production time | 15-30 working days after received the deposit(It depends on your quantity) |

| Sample Charge | In stock sample is free(But the freight will be covered by your side) |

| Payment | T/T 30% as an advance payment and 70% T/T before sending the pole band |

| MOQ | 500pcs |

| Our Advantages: | 1. Fast delivery 2. Factory price 3. Good service |

| Note: | You can directly choose the right type according to our drawing size. |

Galvanizing Thickness Measurement

Q1: Are you a Pole Top Bracket manufacturer or trading company?

A: We are a Pole Top Bracket manufacturer with 12 years of experience.

Q2: What’s the surface treatment for the Pole Top Bracket

A: It’s hot-dip galvanized.

Q3: What’s the Pole Top Bracket used for?

A: The Pole Top Bracket is used to support the insulator on the pole line

Pole Top Bracket: The Complete Guide

- Chapter 1: What is a Pole Top Bracket?

- Chapter 2: Why You Need Pole Top Brackets?

- Chapter 3: Main Components of Pole Top Brackets

- Chapter 4: Technical Specification of Pole Top Brackets

- Chapter 5: Pole Top Bracket Manufacturing Process

- Chapter 6: Step-by-step Pole Top Bracket Installation Process

- Chapter 7: Conclusion

Are you looking for a pole top bracket?

If yes, then this is the right guide for you.

This is because I am going to discuss all the fundamental aspects of the pole top bracket.

The focus will be on the definition, main components, technical specifications, manufacturing, installation process, etc. – you will learn everything in this guide.

Let’s dive right in.

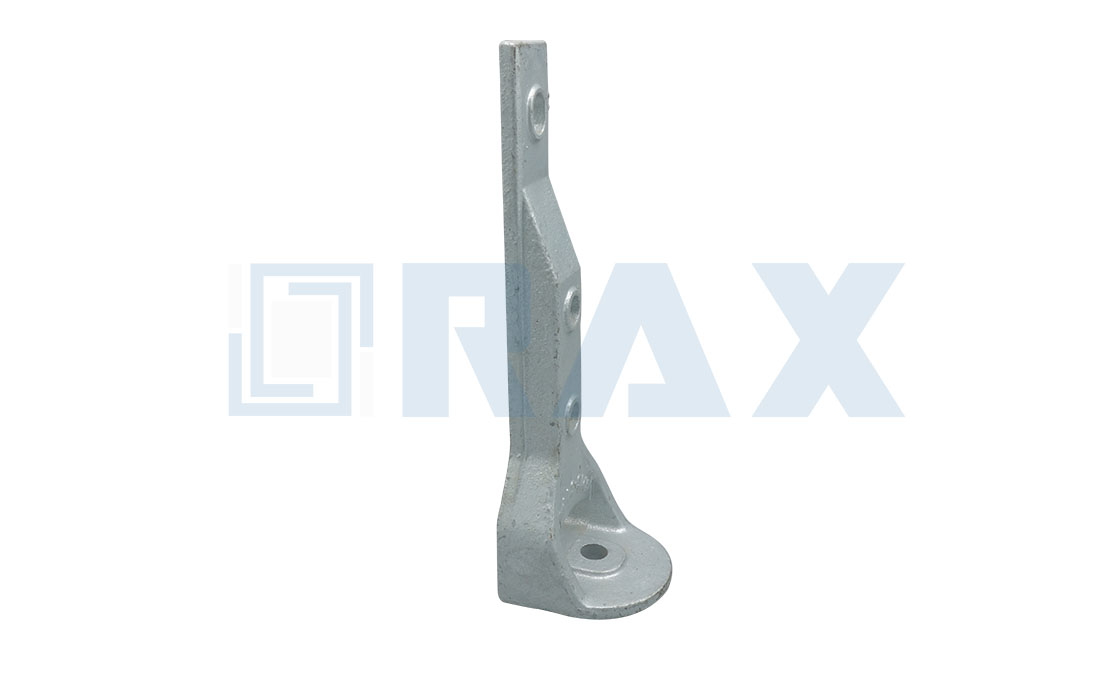

What is a Pole Top Bracket?

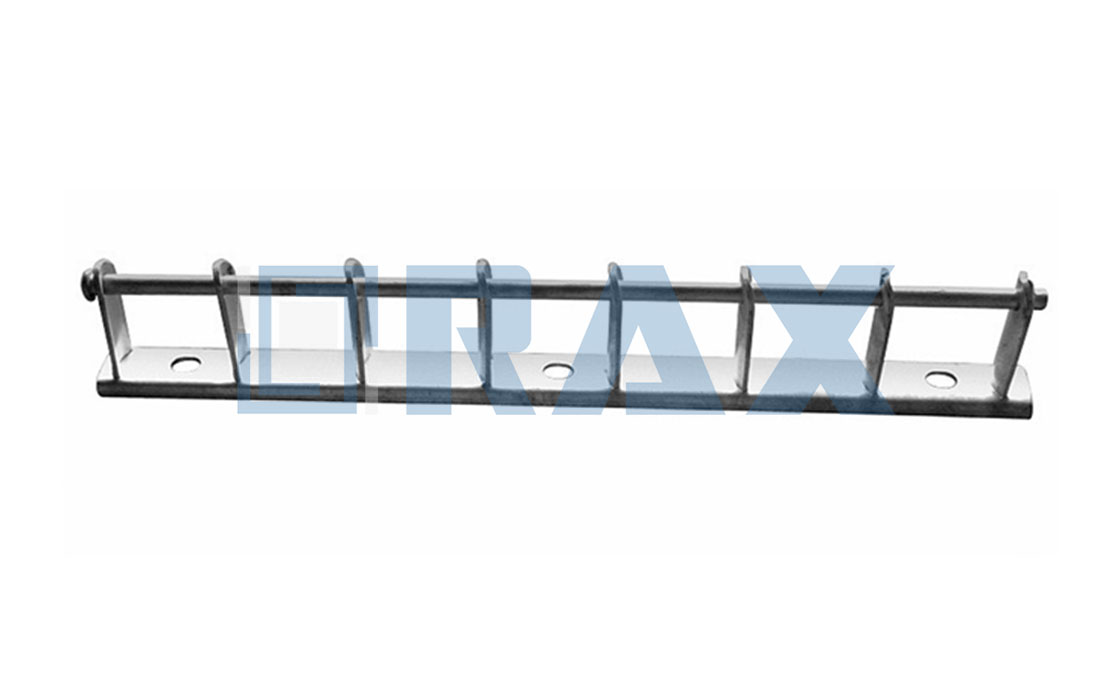

A pole top bracket is a device used on top of poles of different types to hold and support insulators.

It is important in other applications such as mounting cameras and other appliances mounted on top of poles.

Pole top bracket

Pole top bracket

It securely fits a pole top installation vertically directly above the midpoint of the pole for better and regular appearances.

Why You Need Pole Top Brackets?

Pole top brackets are integral parts of pole line hardware used in many applications as explained below.

They work on top of steel, wood, concrete, or composite poles.

It is used to support a post insulator at the top end of a utility pole

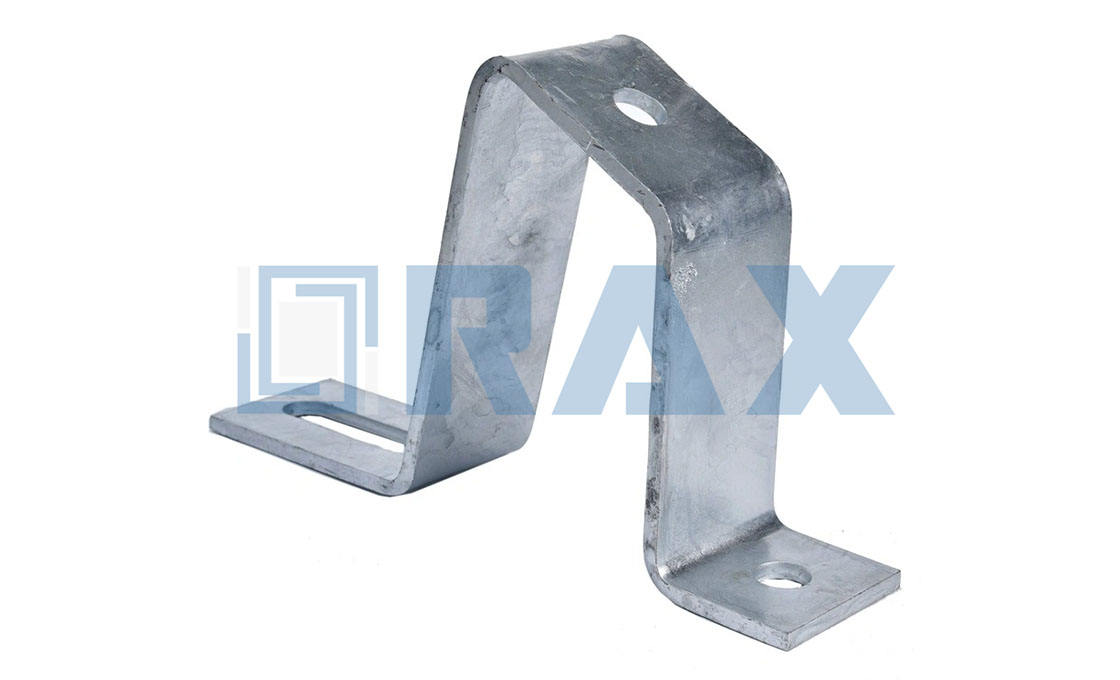

It also has an open neck for the movement of the wrench.

Apart from that, it has an open slot at the bottom to allow for installation and removal of the pole top bracket.

The other feature is an offset mounting surface which provides for the clearance of the insulator.

Pole top bracket with an insulator

The ratings on the installed pole top brackets depend on the height of the insulator.

It also provides an increased distance in separating the middle phases.

Besides, it mounts other types of insulators from 15kV through to 34.5 kV to the sides of the poles.

Main Components of Pole Top Brackets

Some of the main components of pole top brackets include the following:

Bolts and nuts

A bolt is a type of fastener with a male thread on its exterior used to join the pole top bracket to the poles.

It has two ends with a male thread on one end and a solid head on the other.

In most cases, the bolts work in conjunction with the nuts to fasten and join separate parts.

Nuts, on the other hand, are fasteners with threaded holes used together with a mating bolt to join different parts.

Bolt and nut

The bolts and nuts stay together via a combination of forces such as friction, compression, stretching, and elastic deformation.

These forces work together to ensure that the bolts and nuts stick together and join the different parts together.

Technical Specification of Pole Top Brackets

Some of the main technical specifications to consider before you buy a pole top bracket are:

Pole top bracket technical specification

Pole top bracket technical specification

Dimension

Pole top brackets come in a variety of sizes depending on the work they will be performing.

There are specific dimensions that you will have to mention and provide when ordering a pole top bracket.

These dimensions include:

- Measurements in millimeters, e.g., length, width, and diameter

- Steel standard

- Working load in kilograms

- Grade of steel

It is also important that you know the dimensions of the other appliances working with the pole top bracket.

This includes the aspects of the bolts such as length and diameter.

Material Type

The type of material used in manufacturing pole top brackets is ductile iron as per the ASTM A -536 regulation.

Other materials such as steel are in use too, making it a powerful and durable appliance.

Metal is known to corrode if exposed to water, oxygen, and all the other factors of corrosion.

The susceptibility of the material to corrosion requires the manufacturer to provide it with a better finish.

The finish is supposed to improve the properties of the material, making it resistant to corrosion.

Most manufacturers pass the appliance through a hot-dip galvanization, painting, or electro galvanization.

Finish – hot-dip galvanization

This is the leading process manufacturers use to improve the properties of the pole top bracket to resist corrosion.

It involves passing the material through hot molten zinc, and as it reacts with the steel, it forms a coat.

The coat makes the material earn extra properties such as resistance to corrosion.

Thickness

Pole top brackets are made thick enough to make it stronger and more durable.

The thicker the material, the stronger and more durable the pole top bracket will be.

However, you have to know that there is a limit to the range of how thick the appliance can be.

Different materials have different ranges of thickness and resistance to breakages.

It is therefore important that you choose a material that is not too thick but is strong enough.

Design

Pole top brackets have a limited range of designs that you can choose from because of their function.

Manufacturers limit the consumers to a certain design to maintain a particular order on the functionality of the device.

It is, however, possible to come up with new models as long as it does not affect the functionality of the pole top bracket.

Tensile strength

Pole top brackets are made to be very strong as they will be used to support very risky appliances such as power lines.

The manufacturer makes sure that yield strength, tensile strength, bending and elongation tests are in order.

Testing the previously mentioned properties follows the requirements of the BS 4360 and KS 02-572.

Apart from the factors mentioned above, tensile strength depends on the material of the appliance.

The manufacturer ensures that the material will withstand unpredictable weather conditions among other hazards.

Pole Top Bracket Manufacturing Process

The process of manufacturing pole top brackets is hazardous and is a reserve for industries.

It is also costly because it requires special machinery which is available in specific sectors.

The danger involved needs you to put on protective gear to help you in case of an accident.

Pole top bracket technical drawing

Pole top bracket technical drawing

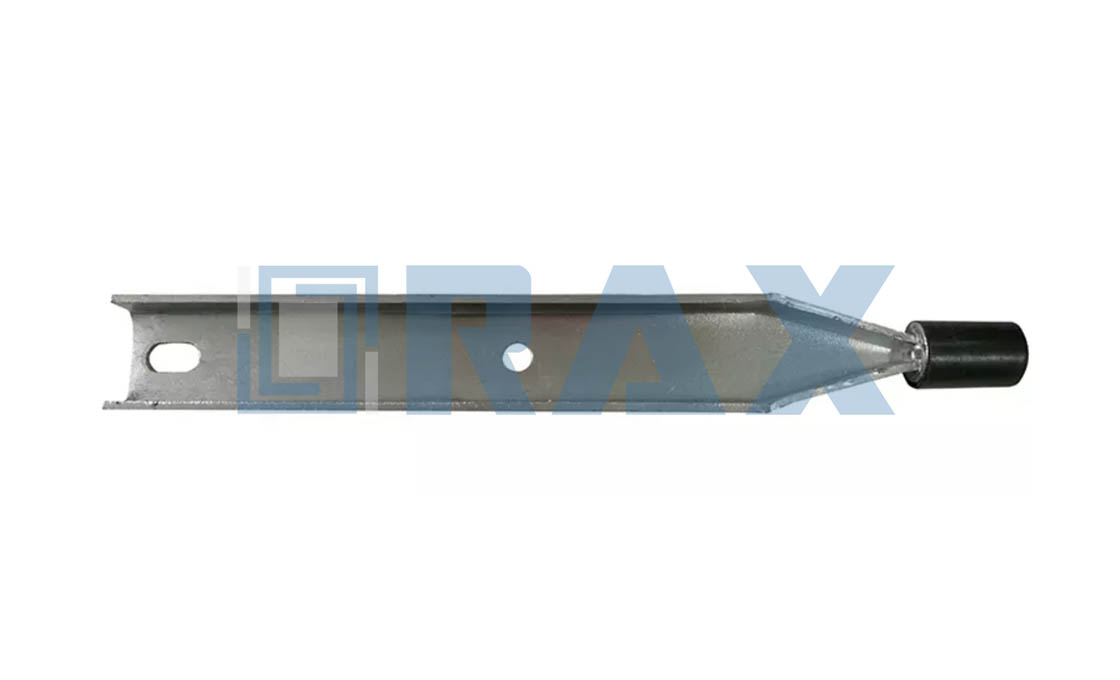

The primary raw material, in this case, is a steel or aluminum alloy that passes through the process of hot forging.

The metal is heated to specific temperatures to make it soft before forging it to the desired shape.

A machine helps in the process of reproducing the metal to form the shape of the pole top bracket.

The next step is the drilling of holes according to the dimensions of the customer.

The aspects to look at include the size of the bolt to anchor the device and the diameter of the other devices.

After that, the device is passed through the process of hot dip galvanization to give it corrosion-resistant properties.

This is the final process before the devices cool down ready for packing and selling.

Step-by-step Pole Top Bracket Installation Process

The process of installation requires you to have all the material you will need at the point of installation.

You will have to seek the assistance of a professional to guide you in the process of installation.

At every point of installation, you are required to put on protective gear to protect you from harm.

With the help of a ladder, you will climb up the pole up to the very top of it.

You will drill the pole to make a hole where the bolt will anchor the pole top bracket.

Remember that the size of the aperture corresponds to the size of the nut.

With the bolt in hand, confirm that it fits well and if not drill more until it is good enough.

After that, take the pole top bracket and mount it against the gains of the flagpole.

The size of the bolt which is in everyday use is the 19 mm (3/4) diameter stud bolt.

Make sure that the mounting surface of the pole top bracket has a tap hole of 20.5 mm in diameter.

Other pole-top brackets allow installation using two bolts of 16 mm in diameter.

The spacing from each center is 203 mm.

Follow all the instructions in the letter because the installation has to be very strong and firm.

It will experience harsh weather conditions such as storms and strong winds; therefore, it has to be very strong.

Mount the pole top bracket in position and make sure the holes match perfectly.

Insert the right side of the bolt into the holes and screw it to the end.

Repeat the same process with the other bolts until the pole top bracket is firmly in place.

Conclusion

Information on pole top brackets makes you understand the type of appliances you need in certain aspects of pole line installations.

At this point, you will be able to know the kind of material to purchase depending on the kind function.

Remember that it can also be custom-made in case you have a particular purpose for the pole top bracket.

And, to solve all pole hardware installation problems, Rax Industry offers high-quality pole top brackets.

Talk to us for competitive prices on the pole top bracket.