Insulator Tie

An insulator tie is also called a distribution tie, it is designed to bundle the conductors to the spool insulator or pole top insulator.

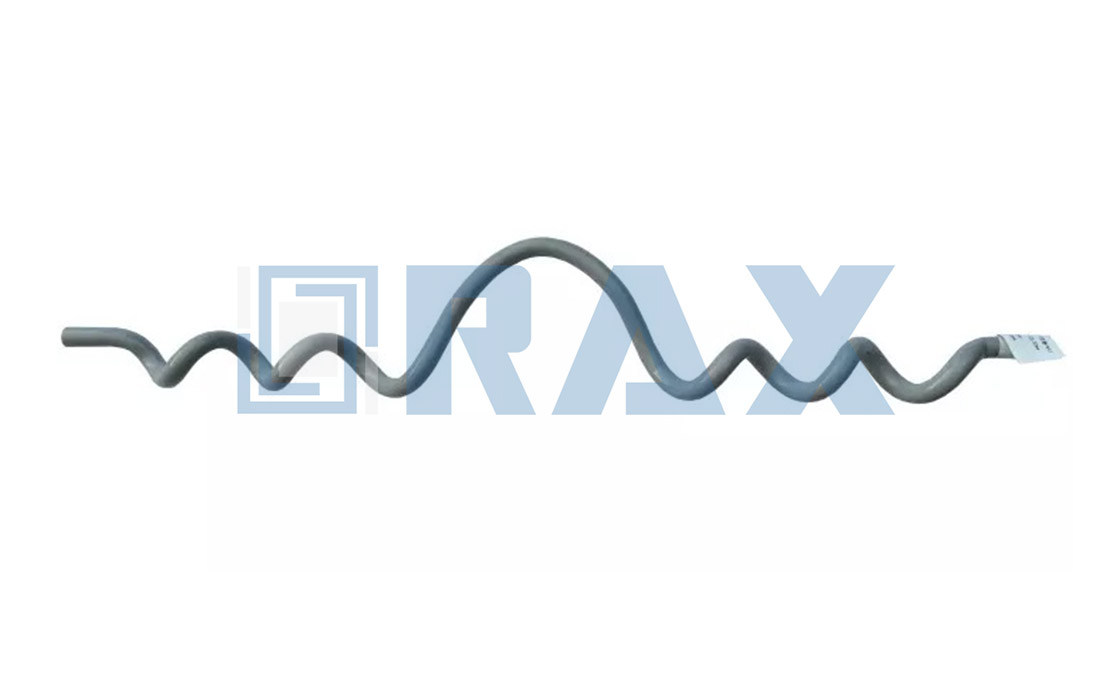

Distribution ties can be made of aluminum-clad steel wire, PVC, or semi-conductor. They are used for different applications, such as ACSR, Compacted ACSR, All Aluminum, Aluminum Alloy, or plastic jacketed conductors.

There are 3 types of distribution ties: top insulators, side insulators, and spool insulators.

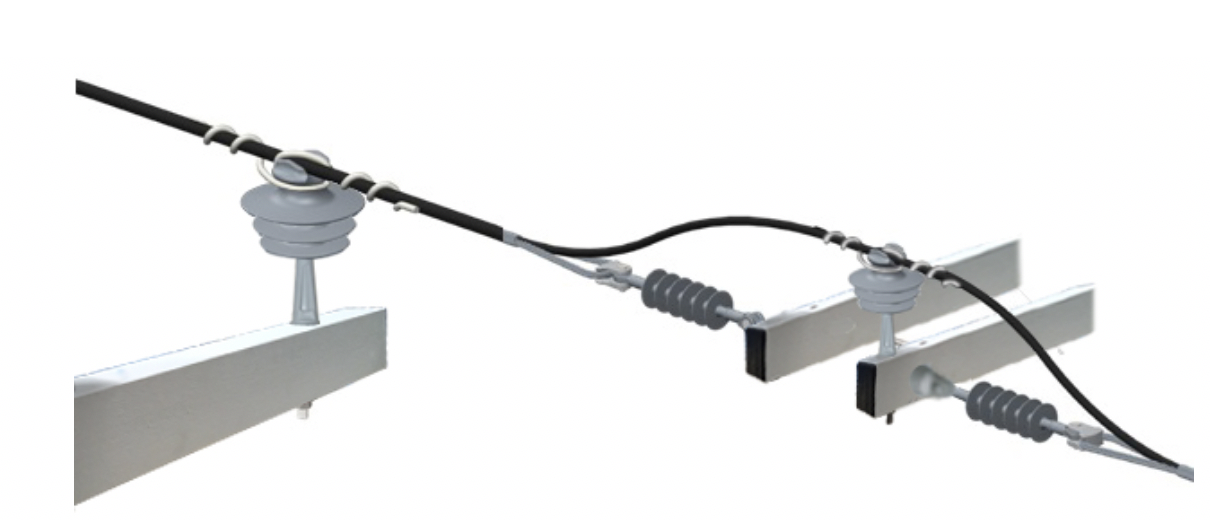

Top tie: The top tie is also called top with ties or ties top, it is used to secure the line conductor to the top groove of the pin insulator.

Side tie: Mounting the conductor conductors to the side groove of insulators.

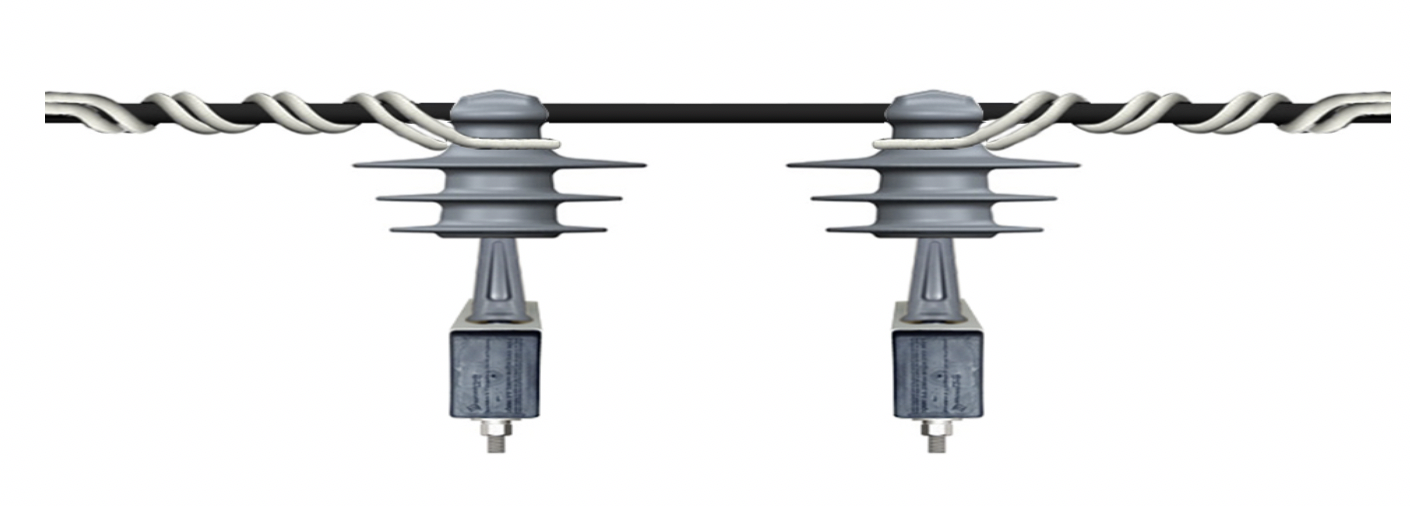

Spool insulator: Tying the conductors to the spool insulator.

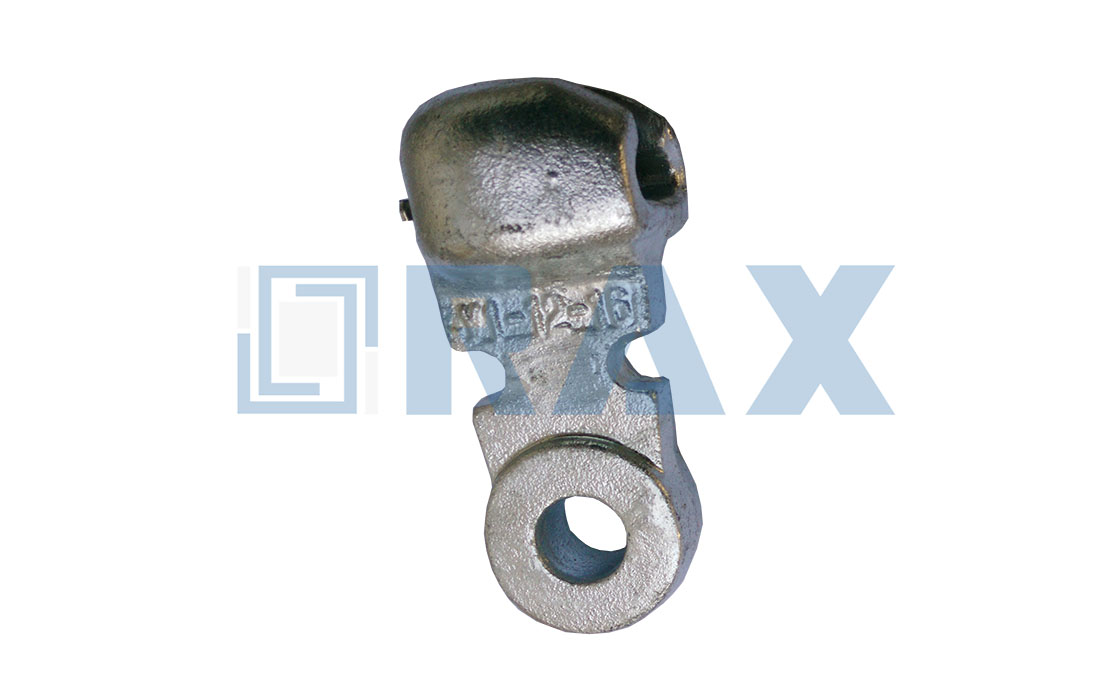

One full set-insulator tie, usually includes a preformed guy grip, neck tube, and label.

The insulator tie affects better than the clamp top insulators and hand ties over armor rods. It has the features of easy installation, uniform design, double support available, and safety. As an ISO-certified manufacturer and supplier, Rax Industry top tie is more efficient to satisfy the power instructions nowadays.

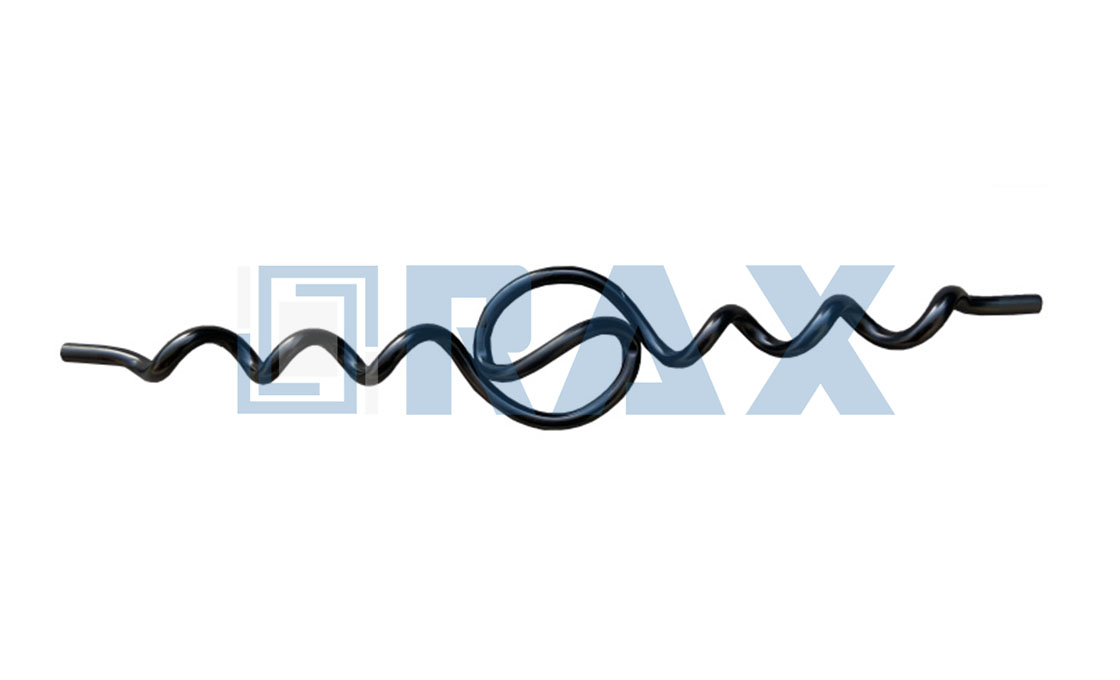

I. Preformed Single Top Tie

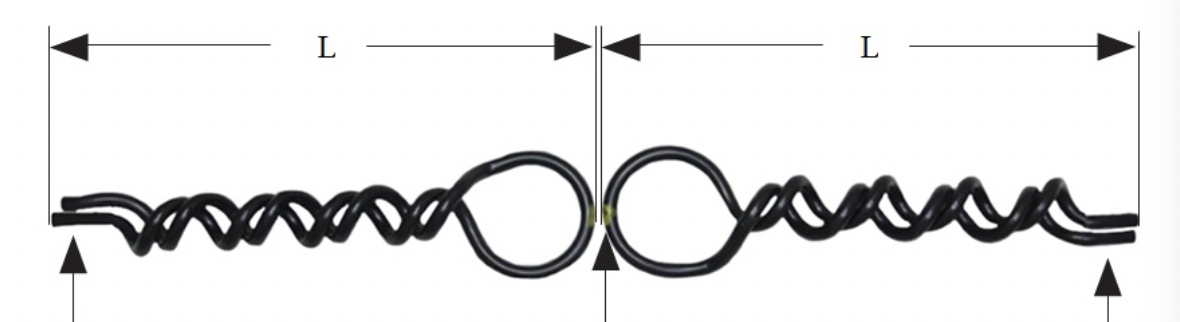

II. Preformed Double Top Ties

Compared with the old tie way by hand, Rax Industry top tie has the advantages as below :

1. Rax Industry top tie fastens the conductors more perfectly than the old way. Rax Industry top tie has the unique feature of “rebound resilience”. When the conductors burden little force from the flowing, the top tie can help the conductor rebound back to the insulator curve.

2. The aluminum clad steel has much more strength than the aluminum wire which ties by hand.

3. The wised top tie design can decrease the shimmy when flowing or another outside forcing. In this way, the conductor is protected from abrasion.

4. Rax Industry preformed top tie makes the installation more easily. The preformed machine made the helical shape instead of rolling by hand.

5. Rax Industry top tie performance better on “RIV” characteristic than the hand tie.

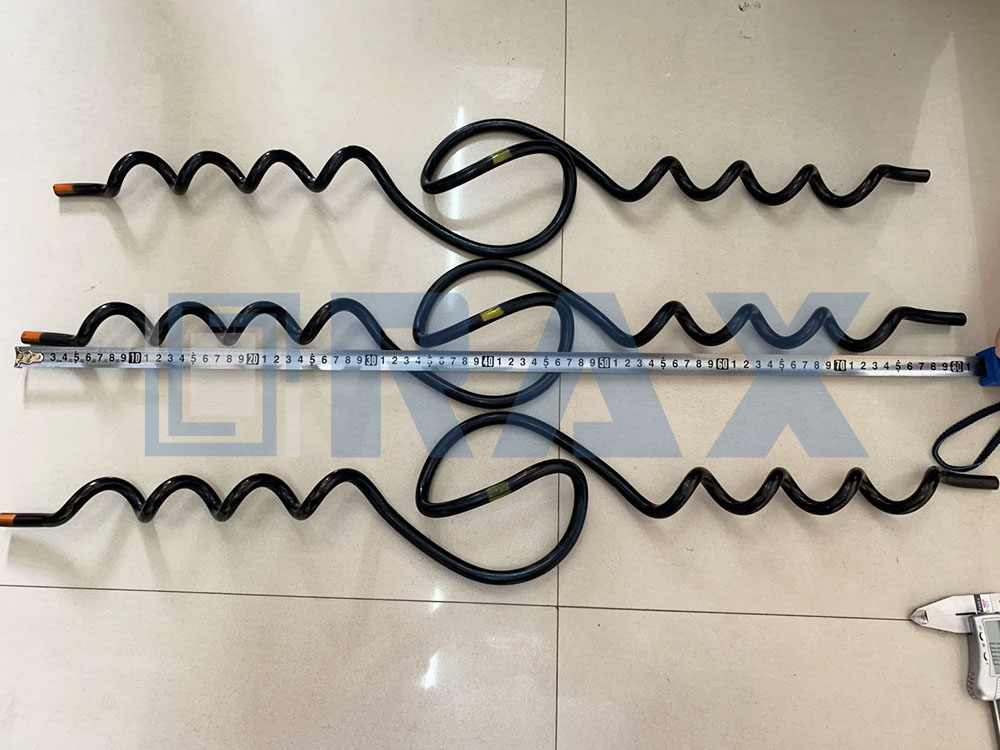

Insulator Tie Testing

Insulator Tie Length Measurement

Insulator Tie Complete Guide

In almost all cases, insulators play the role of shielding the conductors. They prevent the leakage of electric current from the conductor.

Different insulators are designed to play different roles in the electric power line. One insulator type that you may consider buying is the insulator tie.

If you are planning to buy an insulator tie, read on as we give you the ultimate guide for an insulator tie for an overhead pole line.

What is Insulator Tie?

An insulator tie is a type of transmission line insulator that is designed to enhance the protection of the conductor line. The insulator tie is usually recommended as an improvement of the other types of insulators.

An insulator tie is a type of transmission line insulator that is designed to enhance the protection of the conductor line. The insulator tie is usually recommended as an improvement of the other types of insulators.

Insulator ties give the conductor superior protection against corrosion, abrasion, and other forces that induce motion on the conductor. Although they are a common feature on plastic jacketed conductors, they can also be used on sections of the conductor where you have not experienced an abrasion.

What is the function of the Insulator Tie?

Insulator ties provide an alternative method of supporting and securing conductors to the power line. They are the best alternatives to the armor rod and clamp insulators for transmission lines.

The primary role of the tie insulator is to shield the conductor from the leakage of electric current. The insulating material forms a jacket around the conductor hence ensuring that the cable will not have any direct contact with other materials.

In addition to the primary protective roles, tie insulators also help to keep the conductor stable. They ensure that the conductor is not swayed or moved by different forces of motion that can displace it from its original position. The insulator also prevents unwanted vibrations that may trigger instability on the electrical conducting cables.

Another core function of the insulator ties is preventing radio interference. This is a function that you will not find on other types of insulators. This form of protection is vital in case the transmission line passes through areas that are prone to radio waves.

Another unique function of the tie insulator is to provide double support. Here Double-support insulators are used where the transmission line is crossing through highways, roads, and railway lines. The support is also necessary when the conductor is installed at the turn angles and line angles.

Key components of an insulator tie

The main components that make tie insulator function effectively include:

The main components that make tie insulator function effectively include:

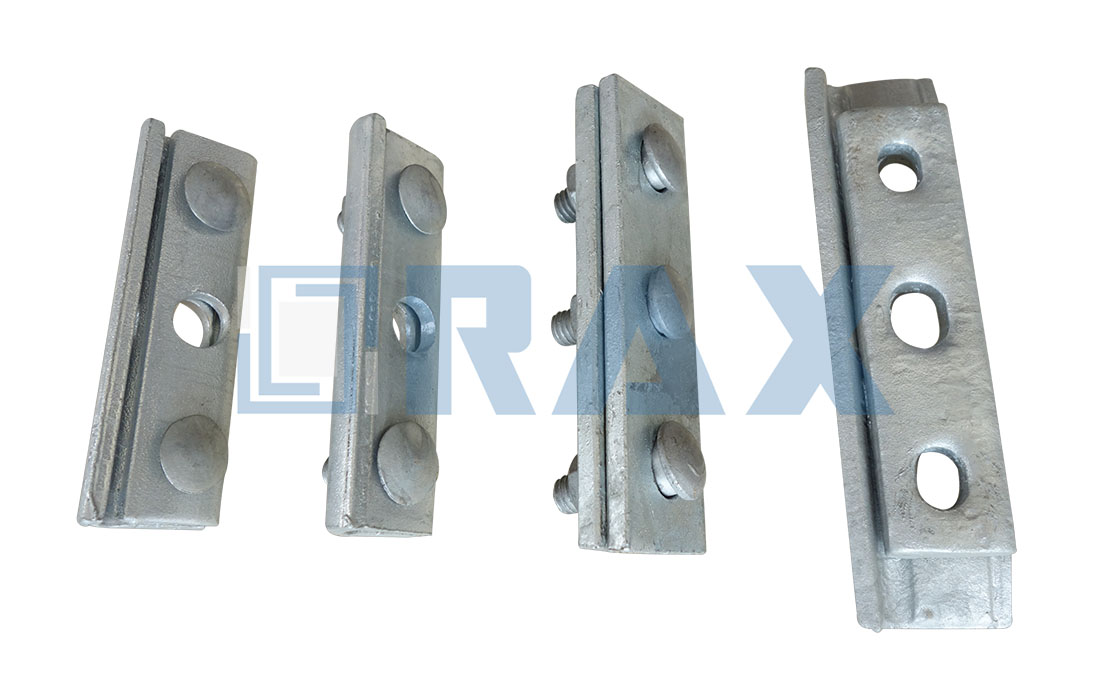

Tie: This component is made of aluminum and it takes most of the force from the conductor.

Pad: The pad of a tie insulator is a component that provides the necessary insulation. It has a plastic material that covers the conductor.

Identification tag: This component helps to identify the insulator tie. It identifies the neck size, the diameter range, the catalog number, and the nominal conductor range.

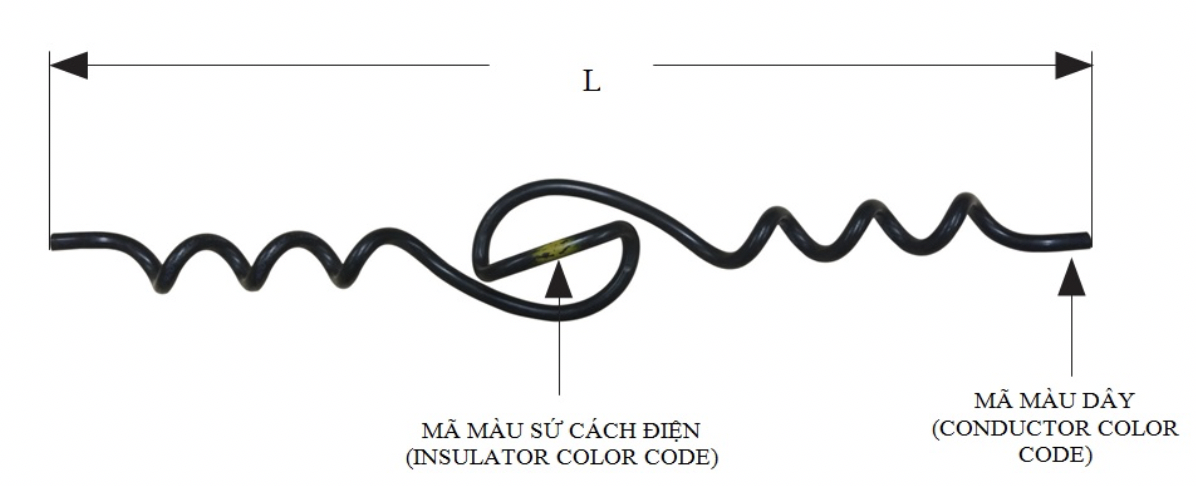

Color codes: The color codes on the insulator are used for identification. The inner color code identifies the conductor size while the outer code identifies the insulator size.

Technical Specifications of Insulator Tie

How can I tell that the insulator tie is suitable for doing its job? The answer is simple. Take a deep look at its technical specifications. They determine the physical and electrical performance of the insulator. They include;

-Mechanical Strength: The insulator should have a high mechanical strength to provide holding support that is required to keep the conductor intact in its desired position. Without strength, the conductor’s weight and other forces will easily break the insulator.

The mechanical strength helps to define the resilience of the insulator. Since the conductors are usually subjected to motion due to different forces, the insulator should allow the motion up to a particular extent. Otherwise, breakage and structural damage are likely to occur.

-Rated voltage: Like most insulators for pole line, tie insulators are rated according to their voltage. Ensure that its rated voltage matches with that of your transmission line. You don’t want to buy an insulator only to realize that it can’t provide adequate insulation since its rated voltage is lower than that of your transmission line.

-Tie insulator ANSI Class: You should also check the ANSI class under which the tie insulator belongs to. The ANSI classes tend to vary and they define the physical and electrical performance of the insulator. For example, the ANSI C29 insulator specifies the different dimensions of the neck diameter. Other features of the insulator that are specified by the ANSI class include the depth of the groove and the transition of the contour into the side groove.

-Weight of the insulator: How heavy or light is the insulator tie? You should take note of this parameter before you buy it.

-Impact strength: Impact strength defines the ability of the insulator to withstand the sudden load that is applied to it. It is advisable to choose a tie insulator that has high impact strength as it is capable of withstanding different loads without breaking.

Maximum size: The size of the tie insulator determines the conductor that it can insulator. The size should match the conductor size for maximum insulation. The size is determined by the top groove radius of the insulator.

Insulator Tie Manufacturer

With all the information that you have learned, probably you are wondering about where to buy an insulator tie. The answer is from an insulator tie manufacturer in China. This way, you can be sure of the quality of the pole line insulator tie that you will get.

Take your time to go through the list of insulator tie manufacturers in China and their respective reviews. You can go further to find out the prices of insulator ties from each manufacturer.

At Powertelcom we are a trusted insulator tie manufacturer in China. Our tie insulators are manufactured to precision and according to international standards with regard to safety and quality. Contact us for more information on everything that you should know about the insulator tie.

Frequently asked questions? (FAQs)

What is an insulator tie?

Insulator tie is also called distribution tie, it is designed to bundle the conductors to the spool insulator or pole top insulator.

How many types of insulator ties?

According to the applications, there are 3 types of insulator ties: top insulators, side insulators, and spool insulators.

What are the key components of an insulator tie?

The main components that make an insulator tie to function effectively include: Insulator identification mark, Tie pad, Identification tag, Color codes.