Secondary Rack

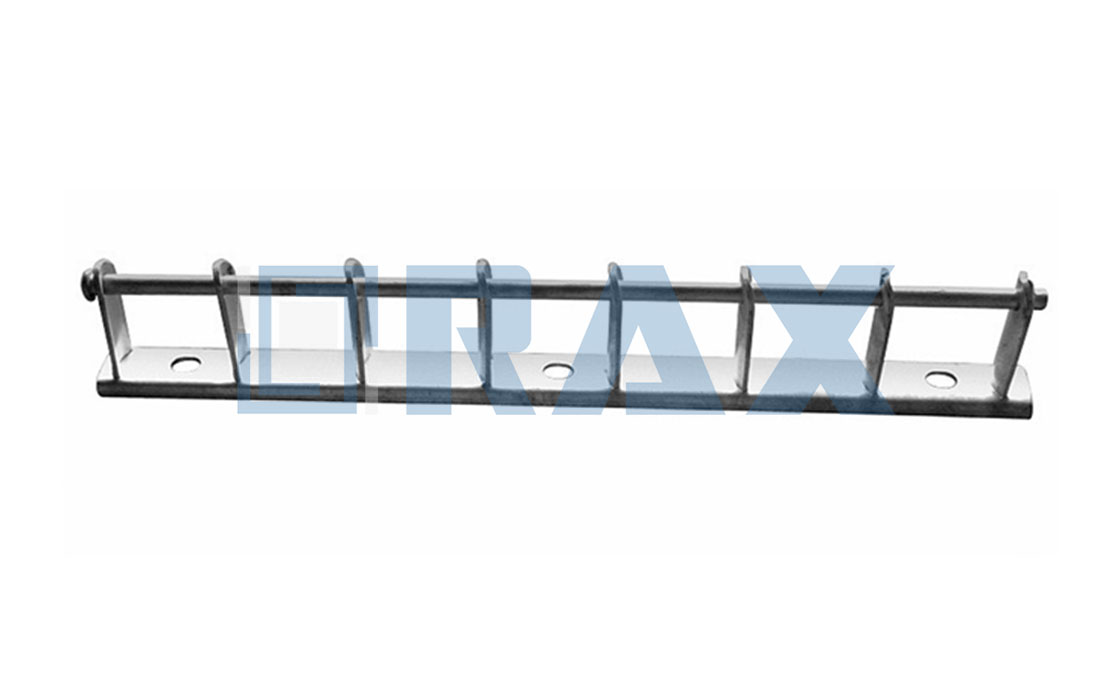

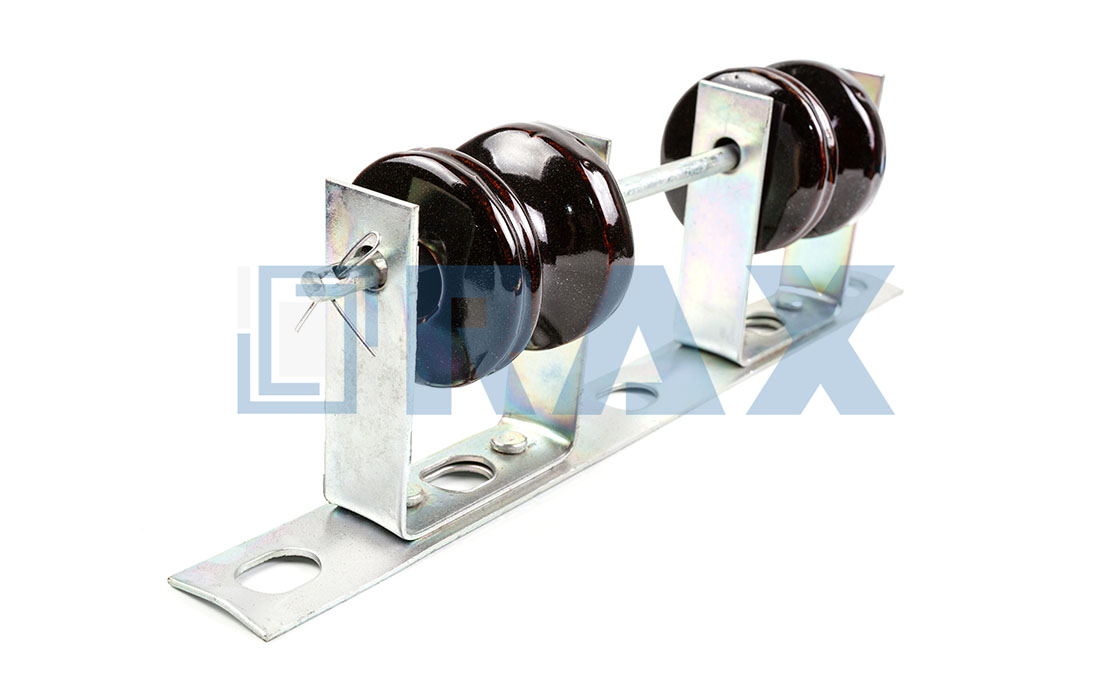

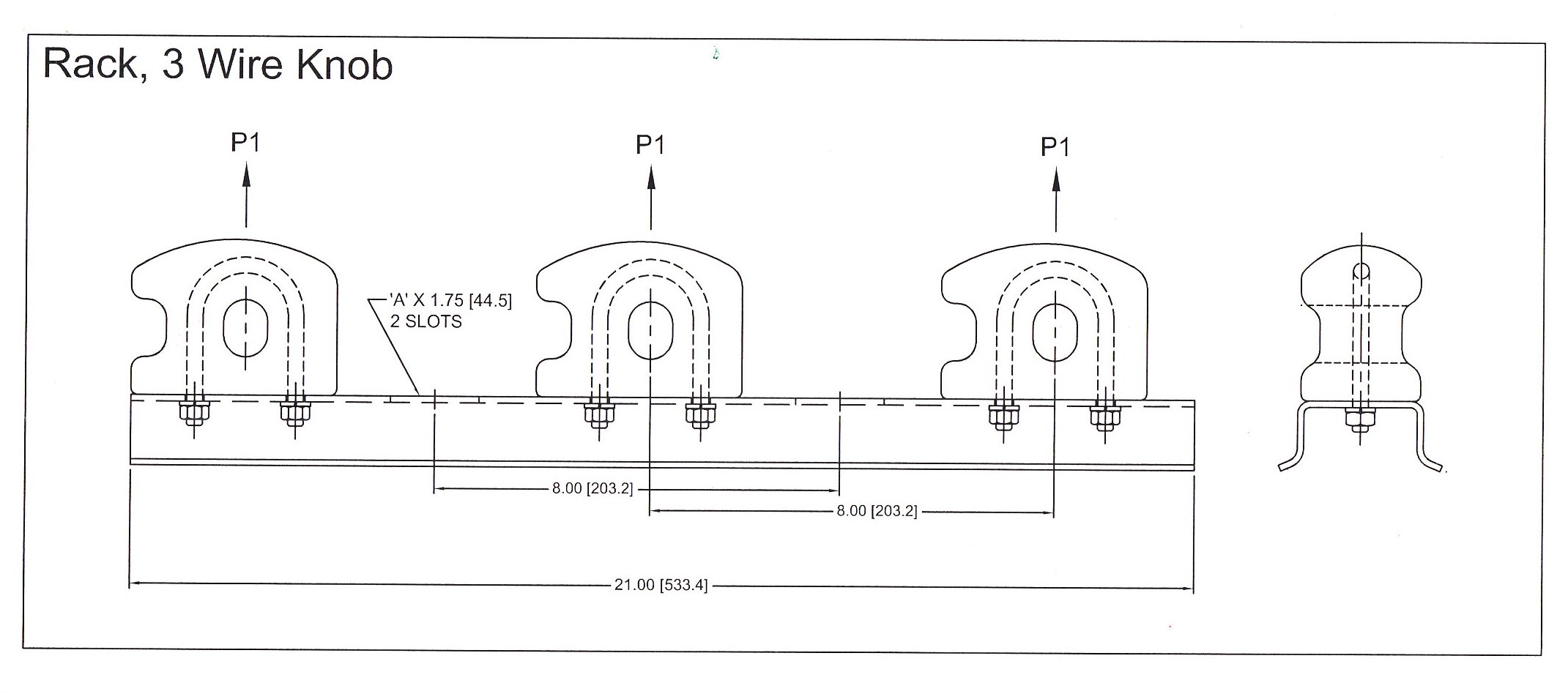

The secondary rack is also called secondary rack electrical. Rax Industry secondary rack is one type of spool insulator bracket. Rax Industry secondary rack includes 4 types. According to the spool number, there are secondary rack 2 spool, secondary rack 3 spool, secondary rack 4 spool, and secondary rack 5 spool.

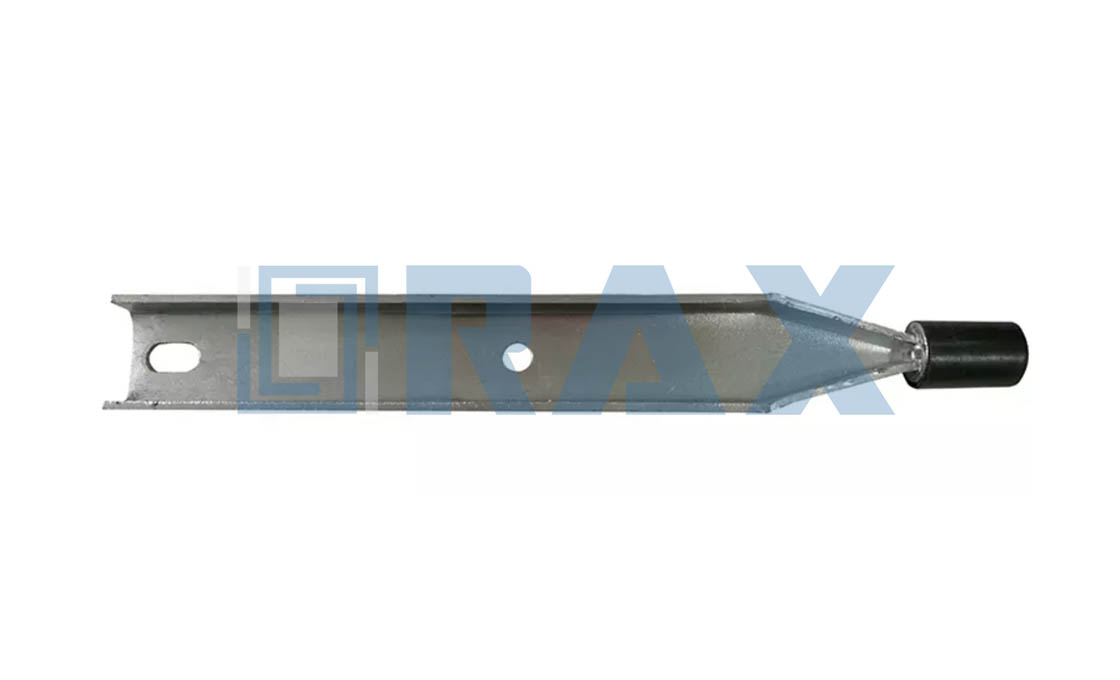

Rax Industry secondary rack has a steel U channel as the base. The base is connected to the utility pole by bolts and nuts. There are curved slots on the U channel, the curved slots are used for the curve racks. This way, the curve racks will be welded firmly when they are put on the slot. There is a hole at end of each curve rack for 5/8 stud to go through. To protect the lineman from being cut by the sharp end of the racks, the sharp end of the rack is stamped out.

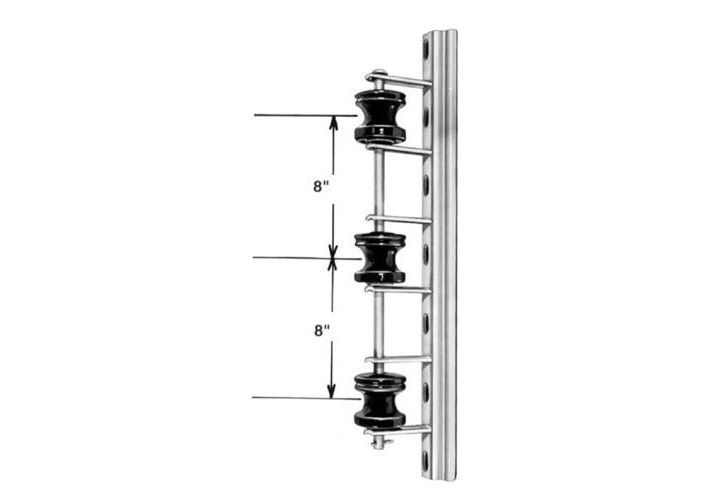

The 5/8 stud with a round head has a smooth surface to protect the spool insulator from scarifying when stringing secondary. The end of the stud is drilled with a hole to fix a stainless steel cotter pin. The Cotter pin will stop the stud from dropping out. Between every two insulators, there is a space of 4″.

The finish of the secondary rack is hot-dip galvanized according to ASTM-123 standard. After hot-dip galvanization, the secondary rack surface is bright and smooth without ribs and lumps.

For different markets, there are different types of secondary rack structures. As an ISO-certified manufacturer, supplier, and exporter, Rax Industry can make a new type of secondary rack according to your design.

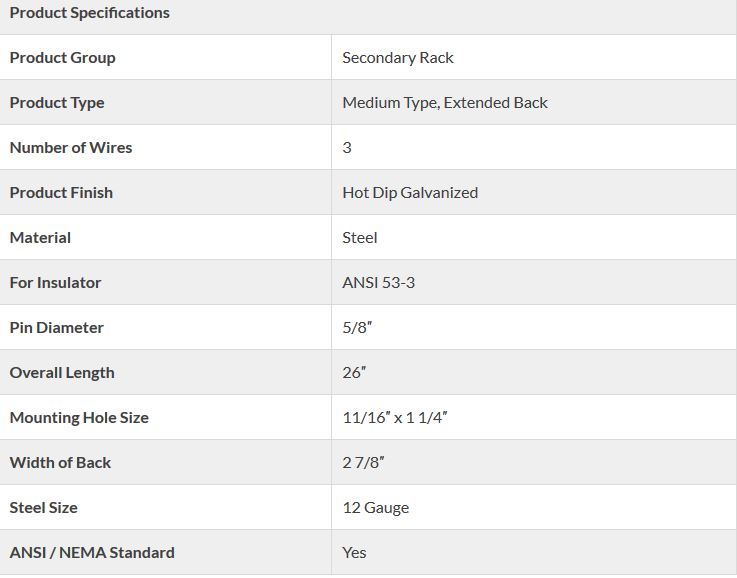

| Product Specifications | |

| Product Group | Secondary Rack |

| Product Type | Medium Type, Extended Back |

| Number of Wires | 3 |

| Product Finish | Hot Dip Galvanized |

| Material | Steel |

| For Insulator | ANSI 53-3 |

| Pin Diameter | 5/8″ |

| Overall Length | 26″ |

| Mounting Hole Size | 11/16″ x 1 1/4″ |

| Width of Back | 2 7/8″ |

| Steel Size | 12 Gauge |

| ANSI / NEMA Standard | Yes |

Secondary Rack: The Complete Guide

- Chapter 1: What is a Secondary Rack?

- Chapter 2: Why You Need a Secondary Rack?

- Chapter 3: Types of Secondary Rack for Overhead Transmission

- Chapter 4: Components and Parts of Secondary Rack

- Chapter 5: Steps in Secondary Rack Manufacturing Process

- Chapter 6: Technical Specifications for a Secondary Rack

- Chapter 7: How to Install Secondary Rack for Power Distribution

- Chapter 8: Frequently Asked Questions on Secondary Rack

- Chapter 9: Conclusion

I know you’re looking for a reliable secondary rack for your overhead line infrastructure.

That’s why today, I am going to show you everything to look for when buying this pole line hardware.

From the basic definition, benefits, applications, and components to designs of secondary racks – I am going to walk you through all the nitty-gritty of this accessory.

The best part?

By the end of this guide, you will be an expert in secondary racks.

So, let’s get straight away to the point;

What is a Secondary Rack?

A secondary rack refers to a type of spool insulator cable support that you attach either on the side or inside of the pole.

In most cases, the design of the secondary rack is in such a manner that it can accommodate two, three, or four conductors.

Secondary Rack

Secondary Rack

The actual spot on the pole where you mount this component can vary depending on whether it’s straight run or dead end.

The basic function of a secondary rack is for supporting the cable on an overhead pole line.

They also help in tightening sagging conductors.

The design, shape, as well as size of secondary racks, are quite different.

Of course, this is on the basis of the load and the particular specifications of the manufacturer.

Secondary rack in a transmission line

And by the way, this is also necessary since it allows you to attain the best option that suits your particular requirements.

Well, speaking of the requirements, it would also be vital to look into some of the common reasons why you would need this accessory.

Why You Need a Secondary Rack?

Inherently, attaining efficiency and optimum performance when constructing an overhead infrastructure requires quality materials and accessories.

So, you’ll find that the need for a secondary rack in such structures is inevitable.

In most instances, you’ll require this hardware to accomplish quite a number of overhead line structures.

Power distribution line

In other words, I’m trying to tell you that a secondary rack is essential in a wide range of pole line infrastructures.

Therefore, let’s quickly run through these applications since I want you to get a clear picture of how important it is;

· Applications of Secondary Rack

The truth of the matter is that you can use this component in various types of overhead line construction projects.

Here though, are some of the most common ones;

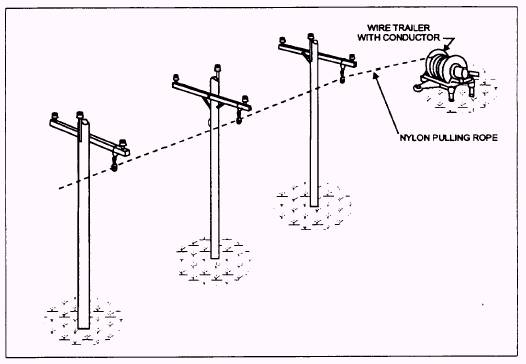

1. Transmission lines

A transmission line refers to a system of various structures, cables, insulators, and other types of hardcore accessories relaying electricity.

This type of line quite often transmits relatively high voltage and can also relay electricity over long distances.

So in this kind of infrastructure, you’ll realize that different types of secondary racks are normally used for stringing conductors.

They are essential given that they make it possible for the conductors to stay in position in the transmission overhead structures.

2. Utility pole mounting

This is also the other common area where the secondary rack is often used.

Basically, a utility pole mounting is a type of column that provides support to the overhead lines and various public utilizes.

Well, this kind of pole is supposed to carry different types of electric lines as well as sub-transmission lines.

For that reason, you’ll undoubtedly need secondary racks to string and fasten the different insulators on this type of pole.

3. Telephone pole line

Secondary racks are also popularly used in telephone pole lines.

Ordinarily, a telephone line is a simple overhead structure that carries a wide range of telephone communication equipment and components.

And it’s for that reason that you’ll indeed require a secondary rack since it enables you to fasten the relevant components accordingly.

So, as you can see, these are the major applications where you’ll need different types of secondary racks.

Of course, there are other applications that are not ideally common, especially in various structures and constructions.

Definitely, this component helps significantly in increasing the efficiency and performance of overhead pole line structures.

And talking of enhancing performance, let’s also look at some of the benefits of this particular pole line accessory;

· Benefits of Secondary Rack

The truth of the matter is that when constructing overhead line structures, you most definitely require secondary racks.

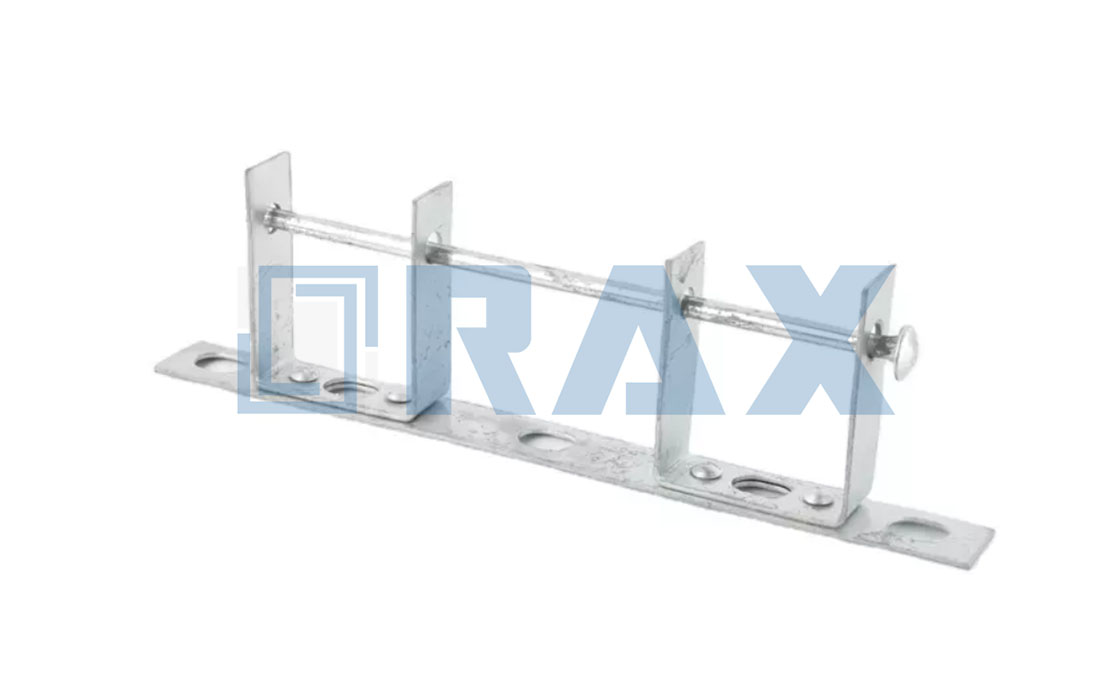

Secondary rack without insulators

Secondary rack without insulators

For that matter let’s now look at some of the benefits that you can obtain from using this type of pole line component.

1. Enhancing safety

If you look at some of the applications that I’ve mentioned above here, you’ll notice that they are rather risky infrastructures.

What I primarily mean here is that you need to ensure that you use high-quality materials and components when fixing the lines.

The reason for this is that any loose fitting might lead to serious injuries and damage to properties.

Therefore, you may need this component as a way of improving the safety of both the users and their properties.

2. Increasing efficiency

The truth of the matter is that using secondary racks in pole line infrastructure is an ideal way of enhancing efficiency.

What I imply here is that this accessory provides ideal support to the insulators.

So it becomes easy to coordinate other functionalities revolving around an overhead line structure during and after installation.

Therefore, your works become easy even when you come back for maintenance purposes.

3. Offers a high level of convenience

This is somewhat related to efficiency, but the fact is that secondary racks increase convenience in overhead infrastructures.

Incidentally, this happens quite often, particularly during installation, repairs, and replacements of other various pole line hardware.

In such instances, it happens that you’ll spend a short time trying to fix the requirements on a pole line structure.

4. Compliance

The thing is, all pole line accessories are under strict regulations.

Of course, this is attributed to the fact that they play a crucial role in holding critical overhead pole infrastructure.

So there is a need for making sure that you comply with the specific requirements that the regulatory body has put in place.

In other words, it is beneficial because it prevents you from clashing with the authorities which at times can be costly.

Reducing cost

What you ought to know is that secondary racks are vital in enabling you to cut various costs.

You see, installation, repair as well as replacement of different pole line hardware can at the time require several components.

But you’ll notice that secondary racks will prevent you from incurring additional expenses.

This is in the sense that they prevent damages that might cost you a considerable amount of money and time to replace.

So basically, these are the fundamental benefits of secondary racks.

And as you can see, they are all crucial and hence making it necessary to incorporate them when constructing overhead line structures.

Now, let’s shift our focus to the possible types of secondary racks you might come across when looking for one in the market.

Types of Secondary Rack for Overhead Transmission

Well, it’s quite imperative to know the many types of accessories that are available in the market.

Of course, it enables you to identify the specific one that you’re certain can meet your needs.

Again, it is also fundamental to know that these components are available in various types.

They vary in different aspects including size, design, shape as well as the manufacturers.

Ordinarily, the varying types of this accessory are often differentiated by the number of spools that each one has.

So to cut a long story short, let me highlight and describe some of the common ones that you’ll get in the market.

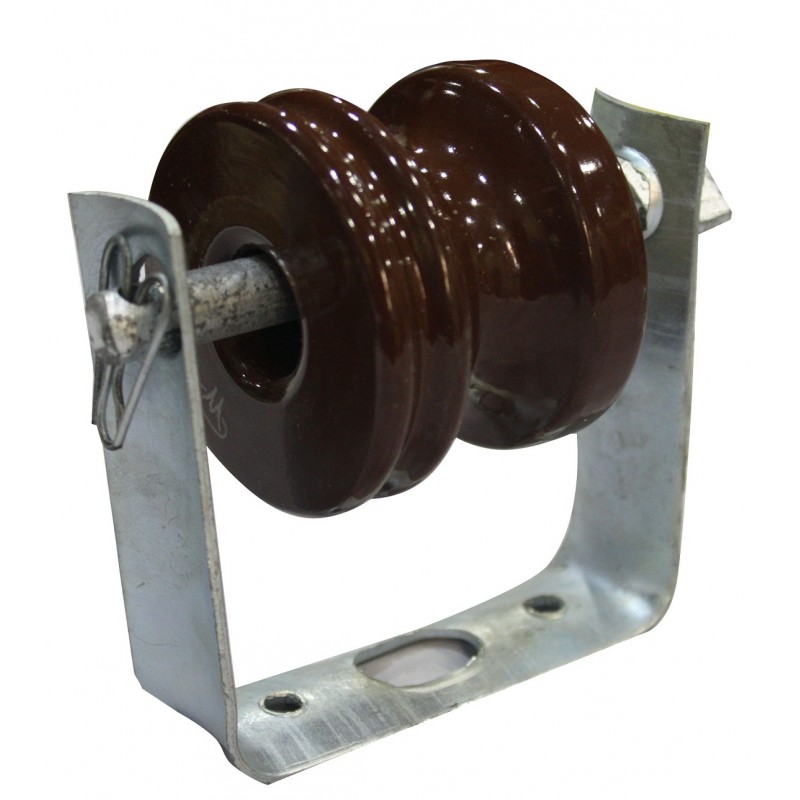

· Secondary Rack 1 Spool

This refers to the type of secondary rack that contains a single spool.

A spool is ordinarily the cylindrical part that has a ridge and an axial hole.

Secondary rack 1 spool

And so as the name suggests, this type of secondary rack only has one pool.

It is common mostly in telephone lines where the cables to be supported are not necessarily more.

· Secondary Rack 2 Spool

Again, as the name suggests, this is a secondary rack that has two spools.

Secondary rack 2 spool

It primarily implies that it can support two parallel conductors.

· Secondary Rack 3 Spool

This refers to a type of secondary rack which can hold up to three conductors.

Three spool secondary rack

It essentially has three spools just like the name suggests.

· Secondary Rack multi Spool

And finally, this is a type of secondary rack which ideally has multi spools just like the name also indicates. It supports 4 up to 10 insulators.

This particular one is relatively large and quite heavy given that it has to support many insulators.

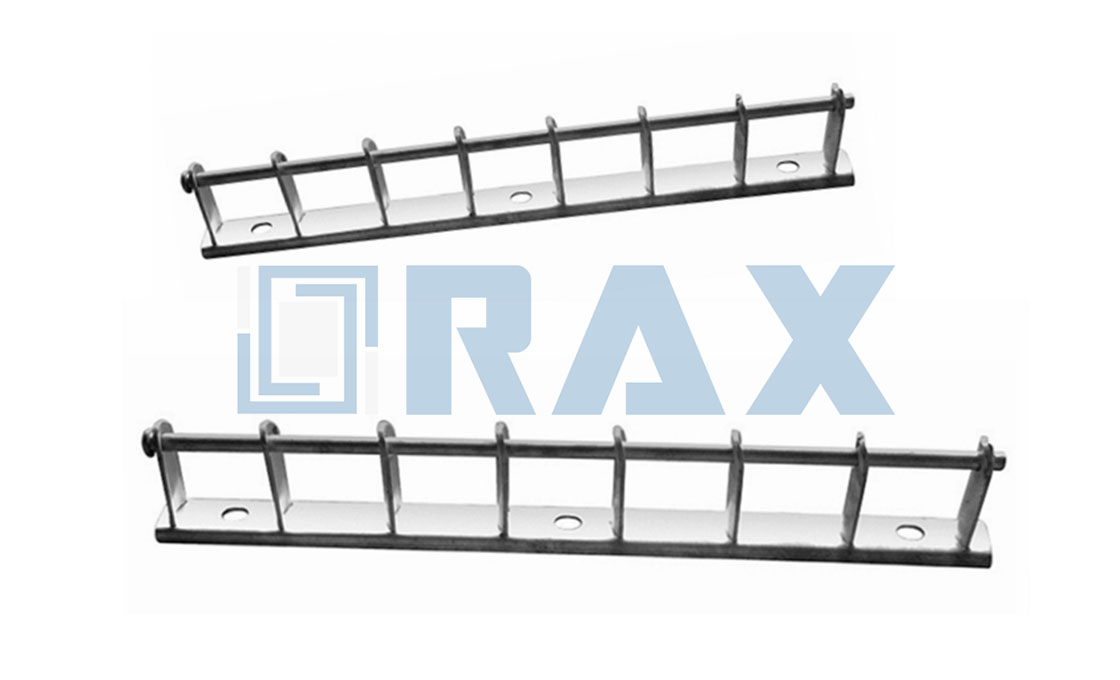

Incidentally, these are the types and designs of secondary racks that Rax Industry Electrical Equipment produces.

Secondary rack multi spool

Secondary rack multi spool

It means that it has multi compartments for fixing the conductors.

Components and Parts of Secondary Rack

By the way, understanding the components of this particular rack is essential.

Probably you’d think that its size is somewhat small to have many components.

But surprisingly, it has quite a number of components that would be ideal if I also discuss herein albeit briefly.

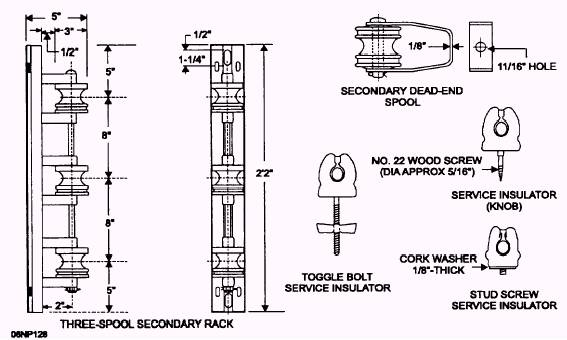

Parts of a Secondary Spool

So let’s have a look at them;

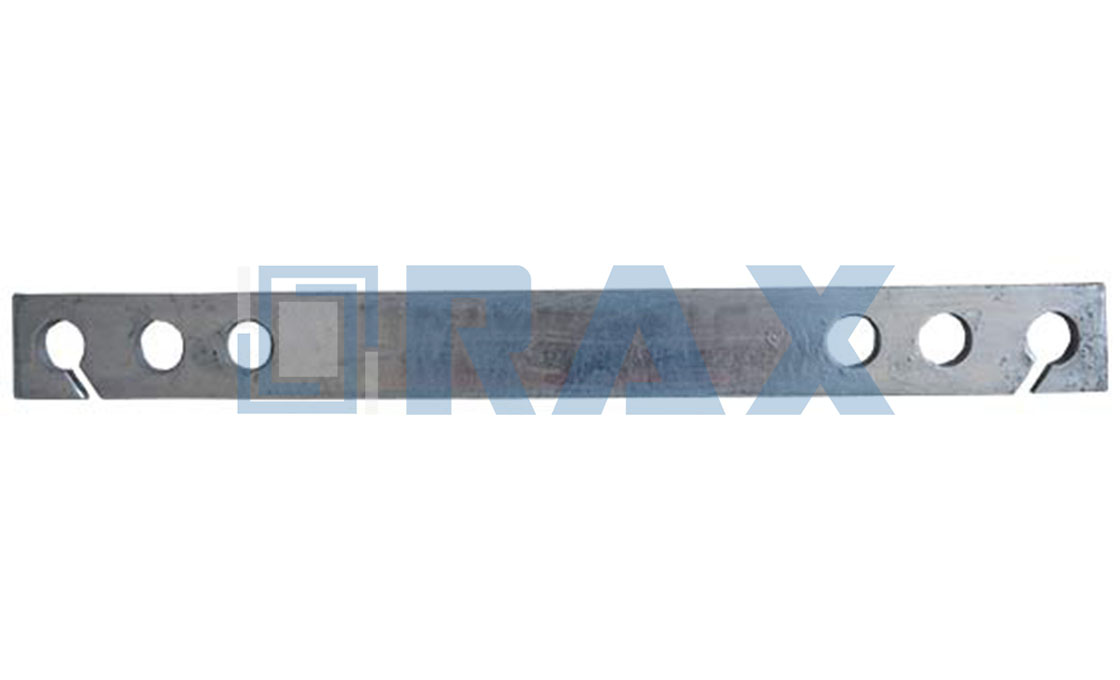

· Base

This refers to the bottom part of the secondary rack.

It is the part that lies on the post and also holds all the other components of this accessory together.

Often, it is made of metallic material given that it has to be strong and also resistant to various unfavorable weather conditions.

· U channel

Just as the name suggests, this component takes a U-shape and is vital for stringing the insulators in an overhead line infrastructure.

It is also made of metallic material due to the nature of the task that it performs which requires it to be strong.

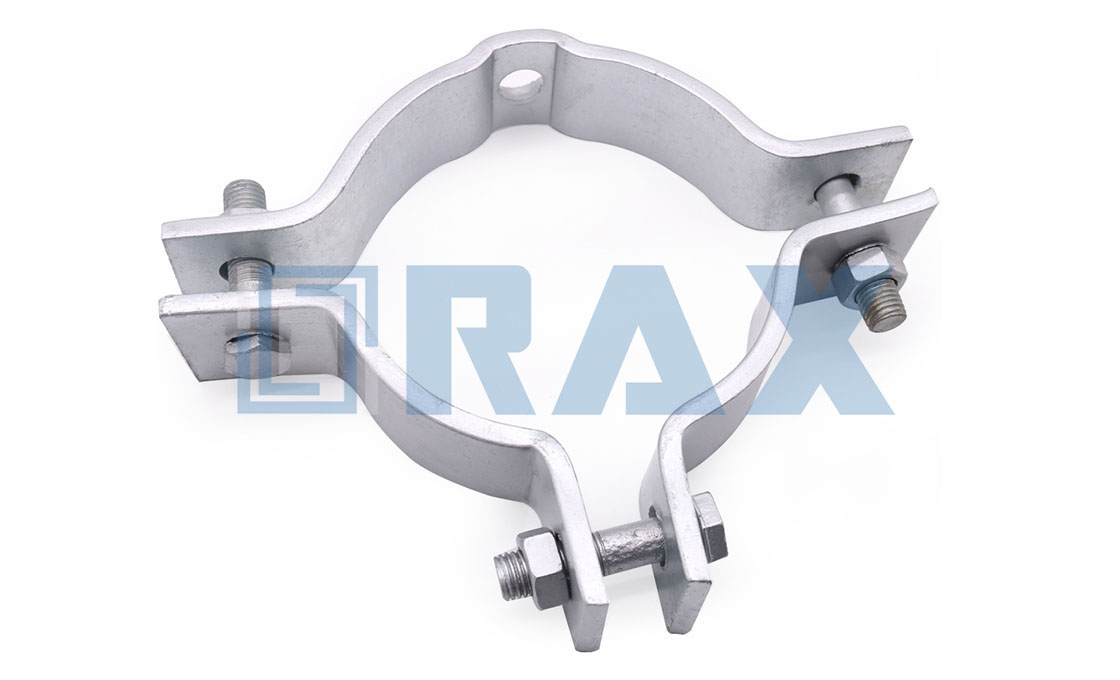

· Bolts and Nuts

Bolts and nuts are ordinarily used for fastening the secondary racks on the pole surfaces.

They’re helpful because they ensure that these components stay put and tight on particular surfaces.

· Holes

These are small rounded openings on the surface of the secondary rack’s base.

The holes are vital because they allow for the driving of bolts and nuts for subsequent fastening of the rack on the poles.

· Insulator

It is the main component that the secondary rack supports.

It merely refers to a material that permits an infrequent flow of electric current.

Insulators are significantly helpful in regulating the amount of electric current flowing in a particular transmission system.

· Cotter Pin

This refers to the type of metal that is often used in fastening the joining ends of a U-channel.

· Clevis Pin

On some occasions, you may also refer to it as a clevis fastener.

It is basically a fastener system that appears in three-piece and consists of the clevis, clevis pin as well as a tang.

Ideally, these are some of the key components of a secondary rack that you ought to know.

By the way, it’s important because you’ll always come across them whenever you’re mounting this accessory.

And before moving further, let’s first look at the manufacturing process of a secondary rack.

Steps in Secondary Rack Manufacturing Process

Primarily, manufacturing a secondary rack is not necessarily a difficult one.

In fact, as long as you have all the necessary materials, you can make it at your workshop.

However, it’s always recommended to ensure that you purchase from reliable manufacturers because of the quality standards.

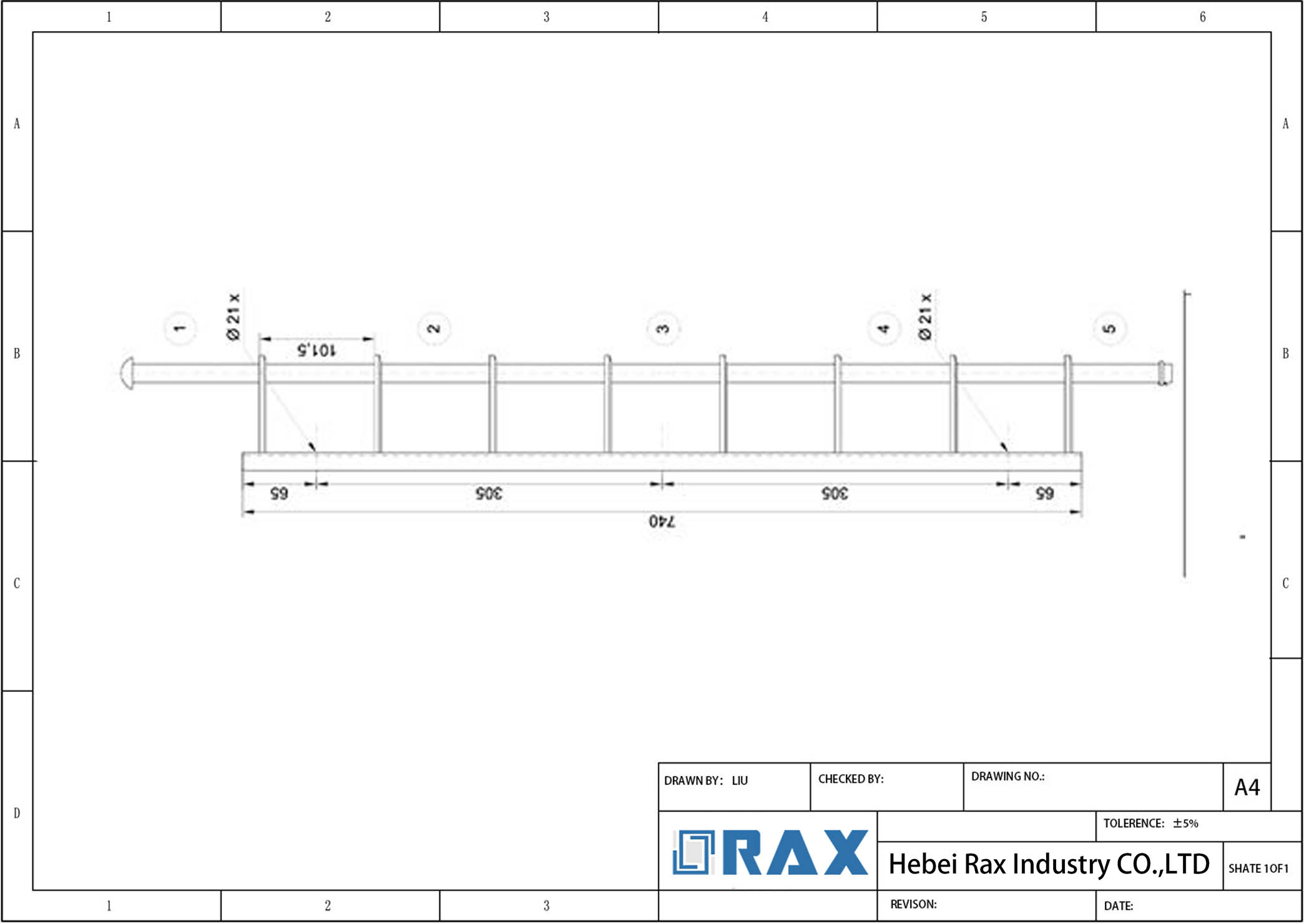

Technical drawing of a secondary spool

So let me take you through the basic steps of manufacturing this particular pole line accessory;

1. Welding Process

Welding, in this case, refers to the method of fabrication for joining the different metallic components of this accessory.

During welding, the appropriate materials are often used especially as a way of making sure that the rack meets the required standards.

Moreover, you have to measure the right dimensions before starting the welding process.

This will allow you to get the right size for the particular application where you intend to use the secondary rack.

2. Drilling Holes

After welding or fabricating the components accordingly, the next thing you got to do is to drill the holes.

And before you actually drill holes, you must first ensure that you mark the points accurately by measuring the length.

So mostly, you need to use a drilling machine that can easily create holes relatively first and conveniently.

Incidentally, the size of the holes should also complement the size of the bolts and nuts that you’ll use in mounting this rack.

3. Riveting

In this case, riveting refers to installing a permanent mechanical fastener on the secondary rack.

The purpose, in this case, is always to prevent instances which at times would lead to loose mounting.

Also, riveting helps to enhance the strength of the entire accessory and also makes it resistant to physical conditions that may hit it.

This process is done using rivets.

These are merely smooth cylindrical shaft that contains a shape that resembles head on one end.

And on the other opposite end, it is what many people like referring to the tail.

4. Hot Dip Galvanizing

Once the riveting process is over, the next thing that takes place is galvanizing.

Ideally, this is the process of application of protective zinc coating to the surface of this accessory.

The purpose of this particular process is to help in preventing the secondary rack from rusting.

Of course, the fact that you’ll mount it in outdoor conditions.

What happens is that all these initial processes often leave the surface of the secondary rack relatively rough.

So one way of making it consistent and appealing is through hot-dip galvanizing.

And also, you must remember that you have to carry out this process diligently to match the required standards.

These key processing steps of manufacturing secondary racks are ideal to know.

At least you get an idea of what takes place before you finally get the final product to use in varied applications.

Technical Specifications for a Secondary Rack

Well, one of the most important factors that you have to consider when purchasing or looking for secondary racks is the specifications.

You see, this accessory plays a fundamental role in determining the efficiency, quality, and performance of this product.

So it’s merely practical to ensure that you look keenly into these aspects before finally deciding on the particular type to buy.

Technical specifications of a secondary rack

Here are some of the key technical specifications to evaluate in a secondary rack;

· Type of Material

Arguably, this is the most significant aspect of a secondary rack that you need to check.

The fact that this is a component that you’ll install on poles and other exposed areas means you need a sturdy material.

It also implies that the specific material has to be resistant to weather, rust, and other environmental factors.

The most common material for manufacturing this product is often steel.

It’s ideal owing to its outstanding and favorable properties for this task.

· Number of Wires

This actually refers to the number of spools that the specific secondary rack you purchase has.

By now, you obviously understand that the designs of this pole line accessory regarding spools vary from one to five.

Therefore, you’ll need to choose a particular one depending on the application.

· Dimensions

In this case, dimension somewhat represents quite a number of factors including a mounting hole, pin diameter, and width of the back.

So it means that you have to be particular when it comes to the dimensions of this specific accessory.

It will help you because eventually, these aspects of dimension allow you to enhance the efficiency and performance of this product.

· Quality standards and certification

One thing you should never fail to consider when sampling the secondary racks is whether they meet the required specifications.

There’s always a regulatory body that provides particular certification and quality specifications that this accessory has to meet.

The other importance of this aspect is that it also helps to enhance the safety and performance of the entire system.

So that you stay with peace of mind knowing too well that everything is alright.

How to Install Secondary Rack for Power Distribution

The truth of the matter is that you need to install this particular pole line hardware appropriately.

Secondary rack

Do you know why?

To make it effective, safe and convenient.

So basically, the process itself is not complicated so to speak, all you need to have are the right equipment for the task.

Installation of secondary rack

- You must ensure that you know the precise spot on the pole where you want to install it. Actually, mark these spots appropriately to know particularly where you’ll have to drill the holes.

- Now, drill the holes whose dimensions correspond with the size of the bolts, nuts, and the holes of the secondary

Remember you need to tighten this hardware on this pole and one way of attaining this is drilling corresponding holes.

- Now pick your secondary rack and place it on the pole. Take the appropriate bolts, and nuts then fasten them to hold the rack

Remember at this time; you ought to enforce safety measures because failure to do so can result in life-threatening injuries.

- Then pick all the other components of the secondary rack and attach them accordingly to the pole. So that you may use them later on when there is a need to.

- Make sure that everything is in place such that by the time you’re leaving the pole this hardware will be able to perform correctly.

Frequently Asked Questions on Secondary Rack

Of course, possibly if you’re a first timer, you’ll always love to know quite a number of factors before purchasing this item.

And it’s for that reason that I’ve seen the need for compiling a few key frequently asked questions as a better way of enhancing your understanding.

So here are some of these questions;

1. How do I select different types of secondary racks?

Definitely, your contractor will advise you on the best one to choose.

However, you may select on the basis of the number of spools that you require.

2. Can I purchase secondary racks in bulk?

Yes. As long as you can determine the quantity that your particular project will require you can always make your order.

3. Do I need an installation manual for the secondary rack?

Yes. It is always important since it guides you on particular steps to follow when mounting this pole line accessory.

4. Can I make my own secondary rack at home?

Yes. It is possible as long as you have all the right materials.

However, it can be costly, laborious, and demanding.

Furthermore, you need to get certification for the items before using them which can be tedious.

5. How do I determine a certified secondary rack?

There’s always a mark of the standard on each of these products.

However, these emblems may vary from one country to another.

6. Can I install a secondary rack alone?

Yes, you can if you have the relevant knowledge and the project is relatively small.

Otherwise, you always need to seek assistance from a certified professional.

7. What happens if the rack is not fitting?

You’ll have to return it to the dealer and get another one.

Alternatively, you may adjust the dimensions on the pole accordingly if possible.

8. After how long do I need to replace the secondary rack?

It depends on both the environmental and weather factors.

But you need always to check to ensure that they’re in right shape.

9. What right size of the secondary rack do I need?

This also is dependent on the type of project you’re handling.

You need to be sure of the dimension before ordering this accessory.

Rax Industry Secondary Racks

Well, as I told you in the first sections of this guide, getting the right place to purchase these items can be difficult.

In fact, as a beginner, you may realize that hustle alone can be quite confusing and tiresome.

The good thing nonetheless, is that I have an ideal suggestion that you can seek these items.

Rax Industry is a leading manufacturer and supplier of high quality and certified secondary racks.

Indeed, this is the best company to seek these products from given that they have all different types of secondary racks.

So next time you want to buy these items just visit Rax Industry and get the best quality for your various needs.

Conclusion

Ideally, this guide has been an eye-opener for you especially if you’re reading it for the first time.

Gladly, you now know several aspects are revolving around this component.

Hopefully, you now know the applications, types, parts, manufacturing process, technical specifications, and way of installing secondary racks.

And most fundamentally is that you also know where you can easily and conveniently order all types of secondary racks from.

Nevertheless, if you have any inquiries, kindly contact our support team, and we will inevitably revert to you as soon as possible.

Further Reading

- Pole Line Hardware Guide

- Design Codes and Standards for Power Line Systems

- Overhead Power Line

- Electric Power Transmission

FAQ

What is a Secondary Rack?

A secondary rack refers to a type of spool insulator cable support that attached either on the side or inside of the pole.

How many types of Secondary Rack?

According to the spool number, there are secondary rack 2 spool, secondary rack 3 spool, secondary rack 4 spool, and secondary rack 5 spool.

What is the application of a secondary rack?

Secondary Racks can be used in various types of overhead line construction projects.

- Transmission lines

- Utility pole mounting

- Telephone pole line

What is the cost of a secondary rack

The price obviously depends on various aspects including dimensions, number of spools, design, and material used.

What’s the Secondary Rack price in the Philippines?

Rax Industry will supply you with the factory price which saves you a 20% cost!

What’s the Secondary Rack 3 spool price?

For different markets, there are different designs of a secondary rack, we will quote for you once you confirm our drawing.